Scaffold diagonal bar

A technology of scaffolding and diagonal braces, which is applied in the field of construction scaffolding, and can solve problems such as inconvenient use, low efficiency of disassembly and assembly, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

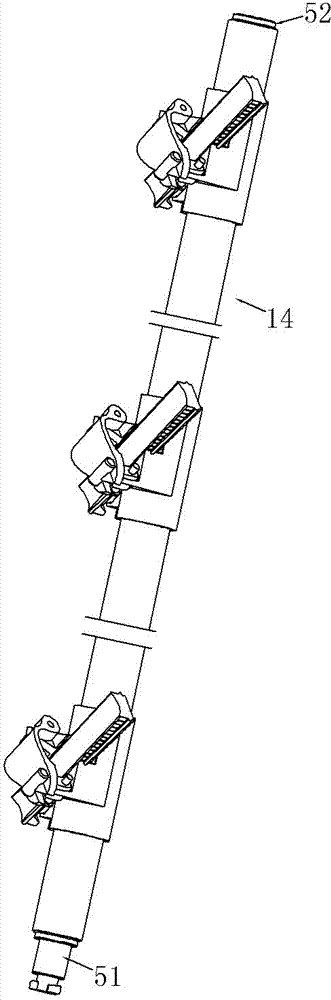

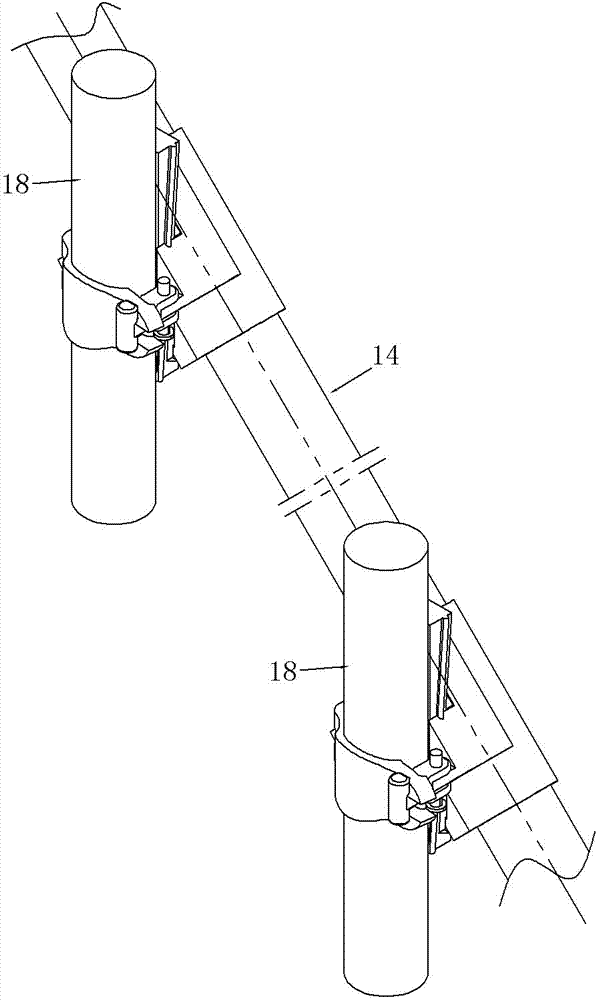

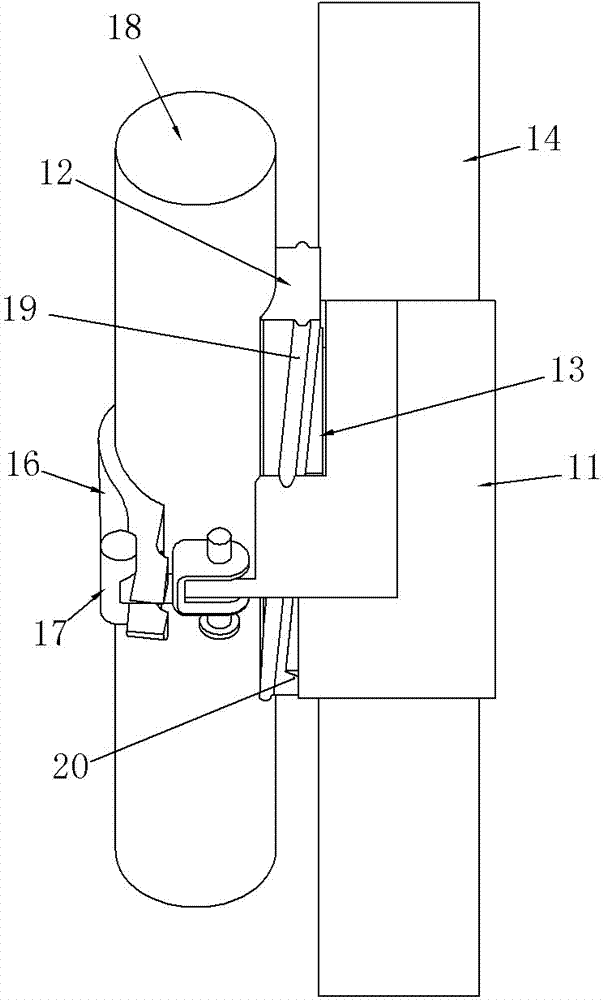

[0035] Embodiment 1 of scaffolding diagonal brace, such as Figure 1-15 As shown, it includes a diagonal brace steel pipe 14, and the brace steel pipe 14 is equipped with a fastener. The fastener includes a sliding sleeve 11, an expansion slider 12 and a compression slider 13. The sliding sleeve 11 is slidably sleeved on the diagonal brace steel pipe 14. On the outside, there are two hinge seats 15, the two hinge seats are oppositely arranged, their hinge axes are parallel to each other and intersect with the center line of the sliding sleeve, the center line of the sliding sleeve and the hinge axes of the two hinge seats Each has a set angle of 45° between them. One of the hinge seats is hinged with a gland 16 for pressing the corresponding scaffold steel pipe, and the other is hinged with a hasp 17 corresponding to the gland 16. In this embodiment, The hasp 17 is a T-shaped buckle, and the gland 16 is lapped and matched with the hasp 17 through the bayonet 101 provided at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com