Antiskid pair of nut

A nut pair, nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of low flexibility, easy to scratch parts, limited use range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

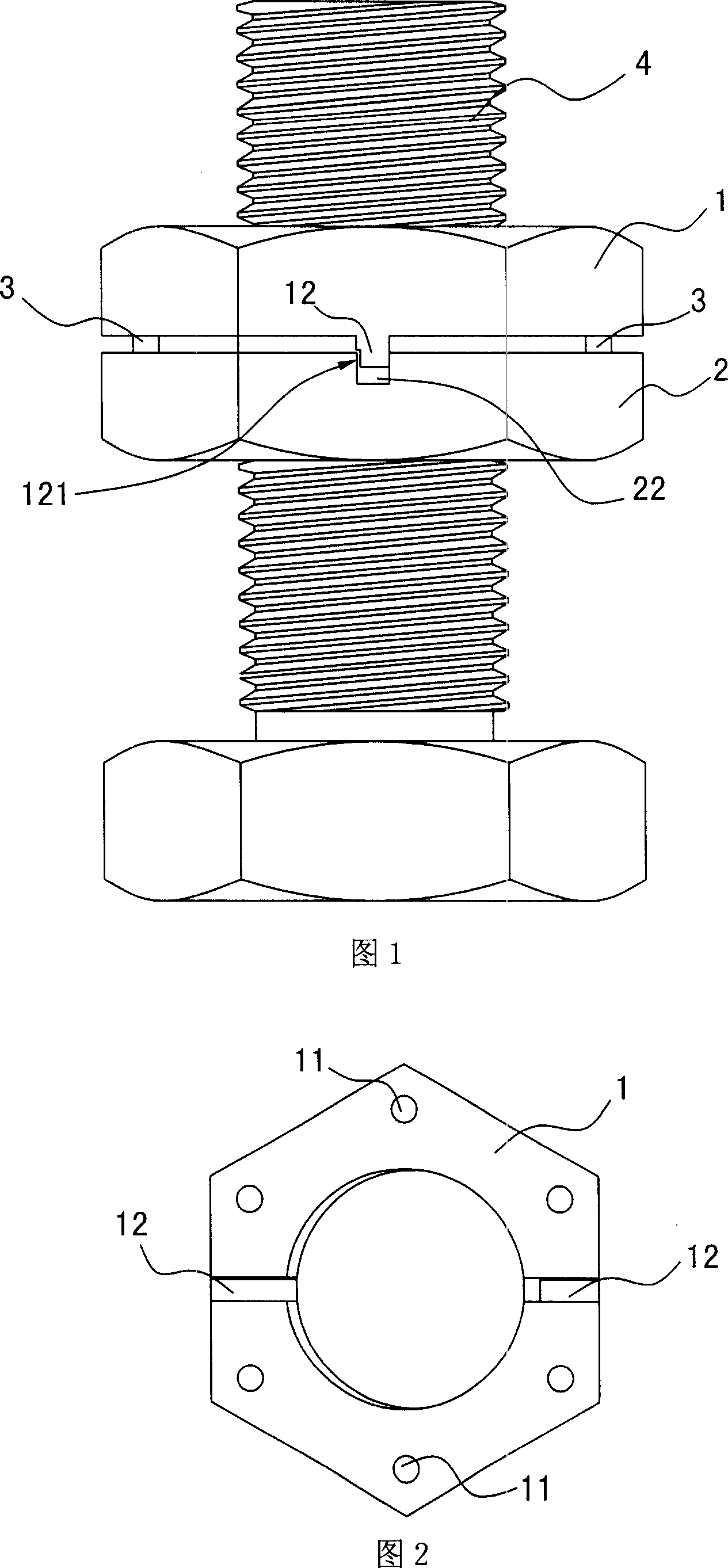

[0019] A non-slip nut pair as shown in FIG. 1 includes a connecting piece 3 and an upper nut 1 and a lower nut 2 that are both sleeved on the bolt 4.

[0020] In this embodiment, the upper and lower nuts 1 and 2 are the upper and lower parts of the same nut after a part is cut off. In specific implementation, the part of a nut whose thickness is half of the thread pitch of the nut's internal thread is cut by a wire cutting method, so that the upper part after the cut is used as the upper nut 1 and the lower part is used as the lower nut 2.

[0021] The upper and lower nuts 1 and 2 are spaced apart from each other. In this embodiment, the size of the interval is half of the internal thread pitch of the upper and lower nuts 1 and 2, that is, the upper and lower nuts 1 and 2 are still cut according to their positional relationship before cutting (within the mutual interval). Half of the thread pitch) is sleeved on the bolt 4.

[0022] Corresponding threaded holes 11 are opened on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com