Efficient rim rotation type automatic positioning device

An automatic positioning and rotary technology, used in positioning devices, clamping, supporting and other directions, can solve the problems of high environmental requirements, scrapped machine tools, high misjudgment rate, etc. The effect of low judgment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

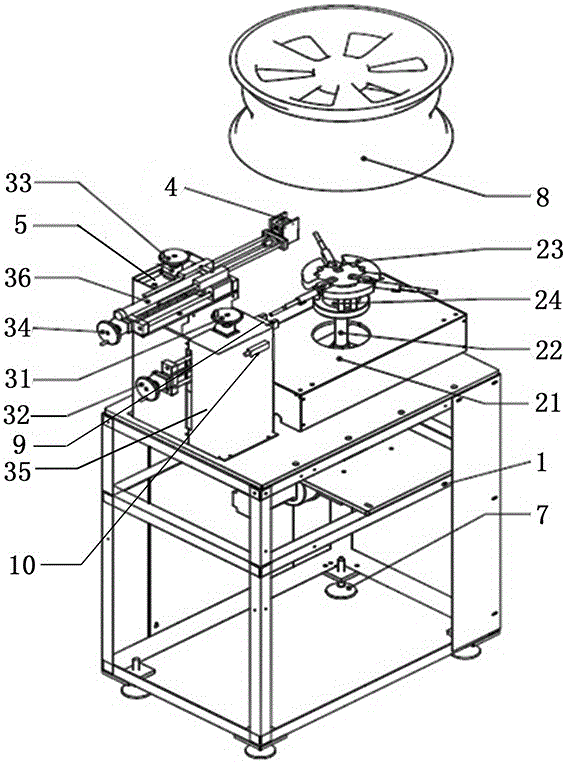

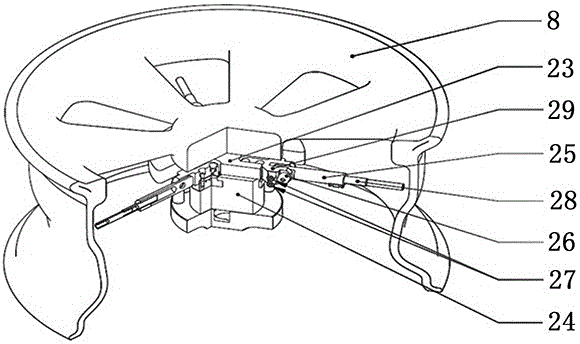

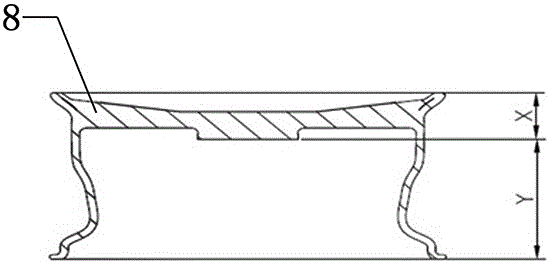

[0028] Such as Figure 1-2 The high-efficiency rim rotary automatic positioning device shown includes a frame 1, a positioning mechanism 2 and an adjustment mechanism 3. The positioning mechanism 2 and the adjustment mechanism 3 are arranged on the frame 1, and the bottom of the frame 1 is also provided with hooves 7. The adjustment mechanism 3 is also provided with a laser range finder 4 . In addition, the high-efficiency rim rotary automatic positioning device also includes an audible and visual alarm 6 , and the audible and visual alarm 6 is electrically connected with a photoelectric sensor 9 .

[0029] Further, in the above-mentioned high-efficiency rim rotary automatic positioning device, the positioning mechanism 2 includes an anti-collision frame 21, a notch is provided in the middle of the anti-collision frame 21, and a rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com