A device for unpacking

A technology of boxes and boxes, applied in the direction of lifting devices, etc., can solve the problems of overturning wooden boxes, difficulty in taking out wooden boxes, waste of production costs and storage space, etc., and achieve the effect of improving strength and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail through specific embodiments below.

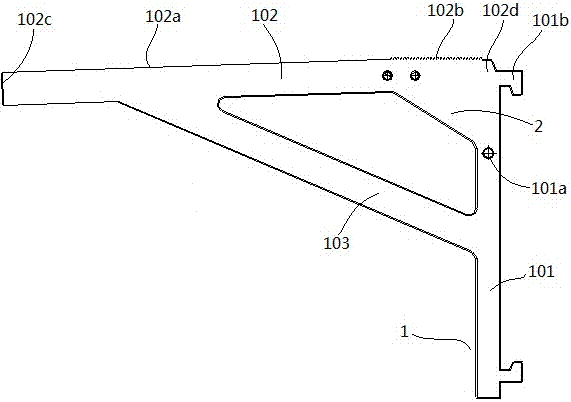

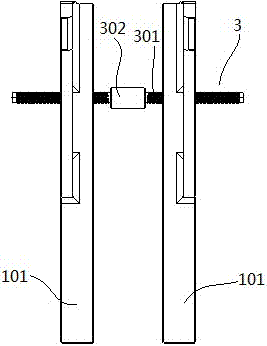

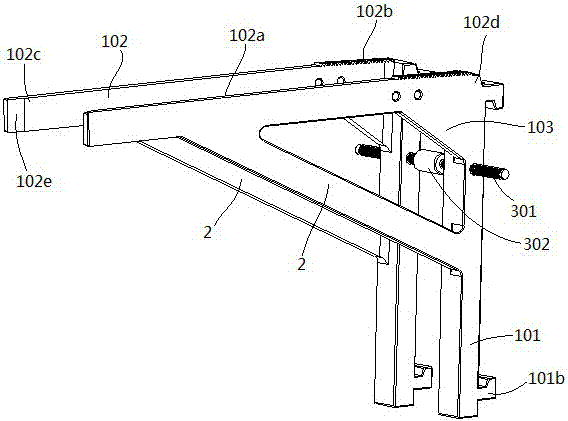

[0019] Please refer to Figure 1 to Figure 3 , the embodiment of the present invention, the box-extracting device is used in conjunction with a forklift to take out the box body, and it includes two sets of L-shaped box-extracting parts 1 arranged in parallel and at intervals. The box-extracting parts 1 include a vertical arm 101 and are located The upper end of the vertical arm 101 and the horizontal arm 102 integrated with the vertical arm 101, the junction of the vertical arm 101 and the horizontal arm 102 is thickened to form a reinforcement structure 103, and the vertical arm 101 is provided with a screw thread The hole 101a and the fork foot structure 101b matched with the forklift, the horizontal arm 102 has a working surface 102a matched with the box, and a plurality of toothed structures 102b are arranged on the working surface 102a;

[0020] reinforcement 2, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com