Template jacking and template bracket using same

A formwork and jacking technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connecting parts, pillars, etc., can solve problems such as inconvenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

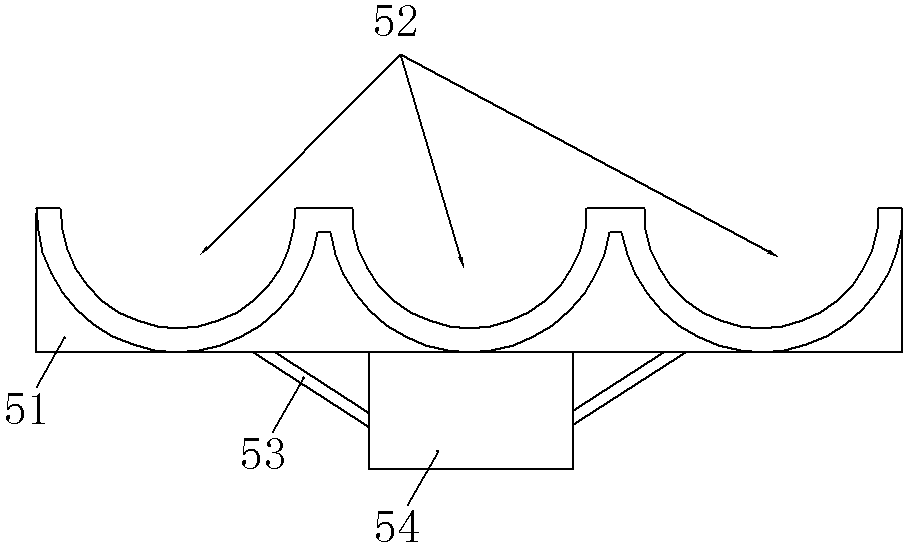

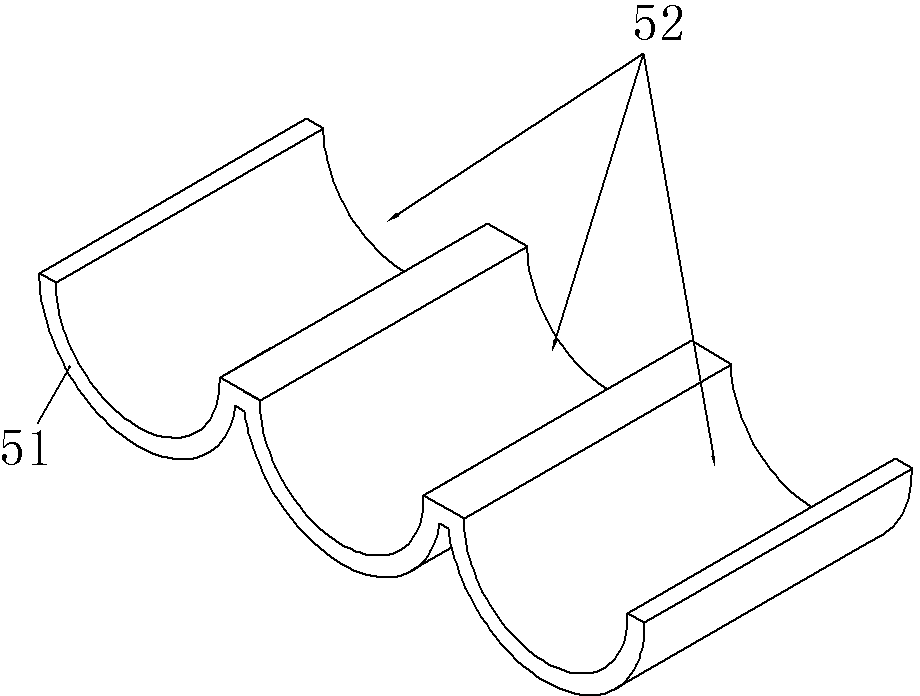

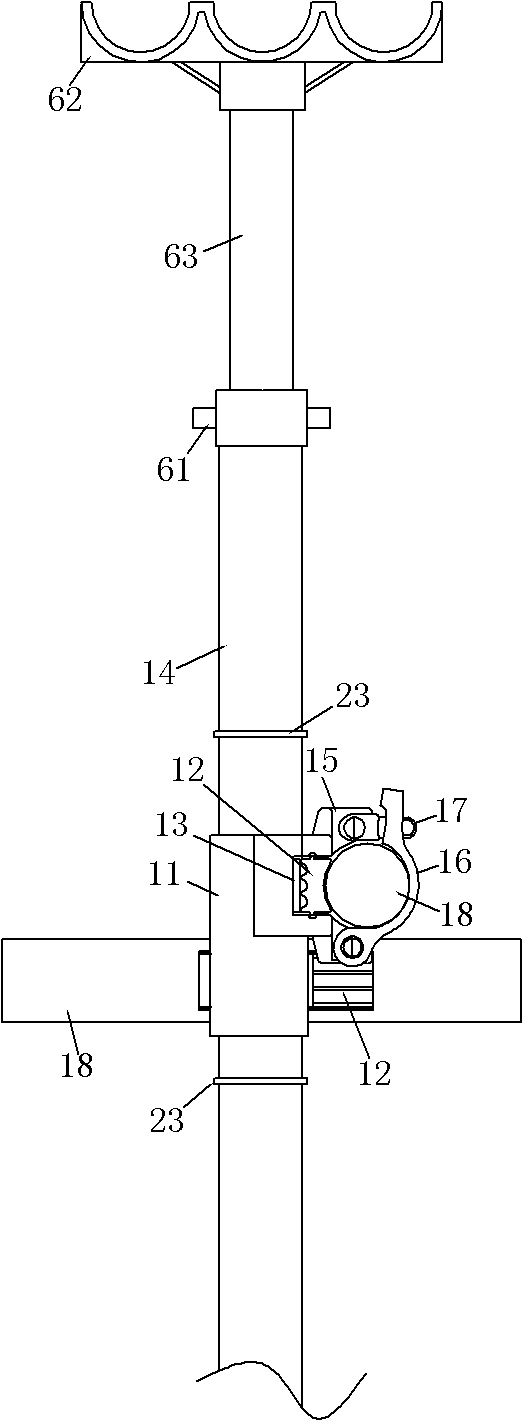

[0033] Embodiments of formwork jacking of the present invention, such as Figure 1-2 As shown, this includes a base body 51. In this embodiment, the base body 51 is plate-shaped, which can be made by means of stamping, casting, etc. The top surface of the base body 51 is provided with a limiting groove 52, and the limiting groove 52 is a through groove. It is used to place cylinders such as steel pipes and prevent the cylinders from slipping or rolling in the radial direction. In this embodiment, there are three limiting grooves 52, and the three limiting grooves are arranged side by side. In addition, in order to ensure that the cylinders in this embodiment The strength of the template jacking, the bottom of the base body 51 is also provided with a diagonal brace 53, specifically, the bottom of the base body 51 is provided with a socket sleeve 54 for connecting with the corresponding pole, and the diagonal brace 53 is supported on the socket. between the sleeve 54 and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com