Automatic cleaning device of monitoring camera

A monitoring camera, automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. Monitoring effect, work safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

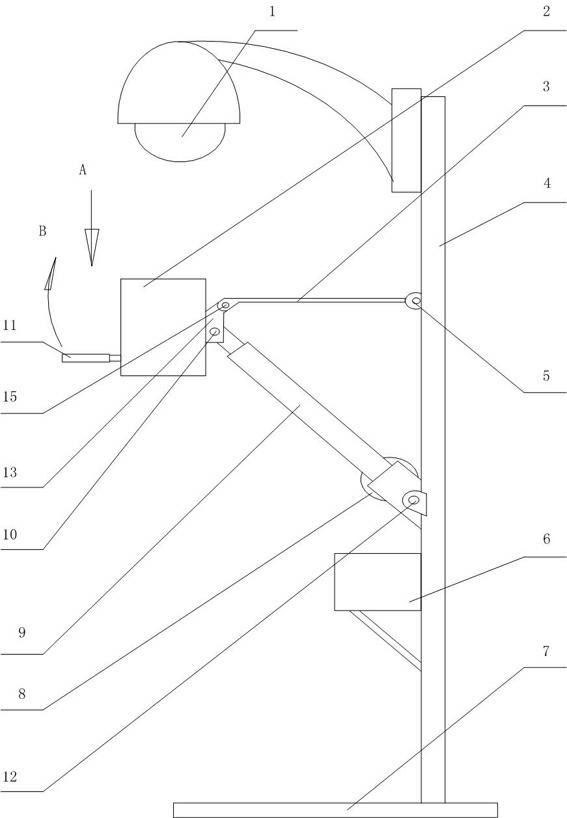

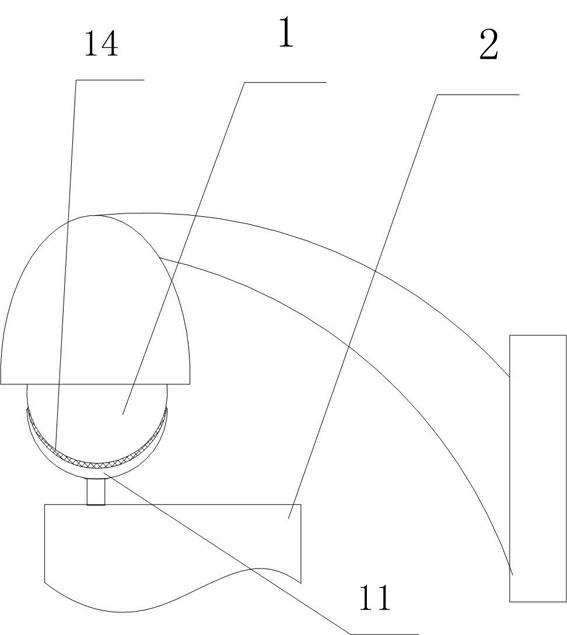

[0015] figure 1 Among them, the monitoring camera 1 is fixedly installed on the base 7 through the pole 4 . On the pole 4 at the bottom of the surveillance camera 1, it is located on one side of the pole supporting the surveillance camera, and the support is installed with a motor that can be pushed up in conjunction with the lifting mechanism to make the rotating brush 11 that is electrically rotated be attached to the surveillance camera 1 outer cover. putter 9.

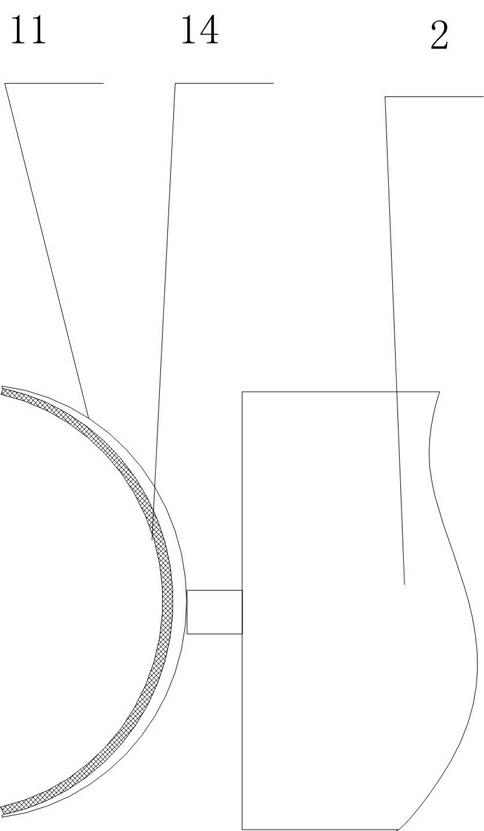

[0016] The rotating brush 11 is in a concave arc shape, and it can be cleaned more cleanly and thoroughly when rotating.

[0017] The installation of described rotating brush 11 is to be controlled by motor 8, the lower end of the electric push rod 9 that can stretch out obliquely upwards, is hinged on the same side that is positioned at the bottom of monitoring camera 1 on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com