Glass clamping device for building decoration

A technology for architectural decoration and glass, applied in the directions of architecture, building structure, application, etc., can solve the problem of low safety of glass clamping, and achieve the effect of improving safety and stability, improving stability and being easy to pull out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

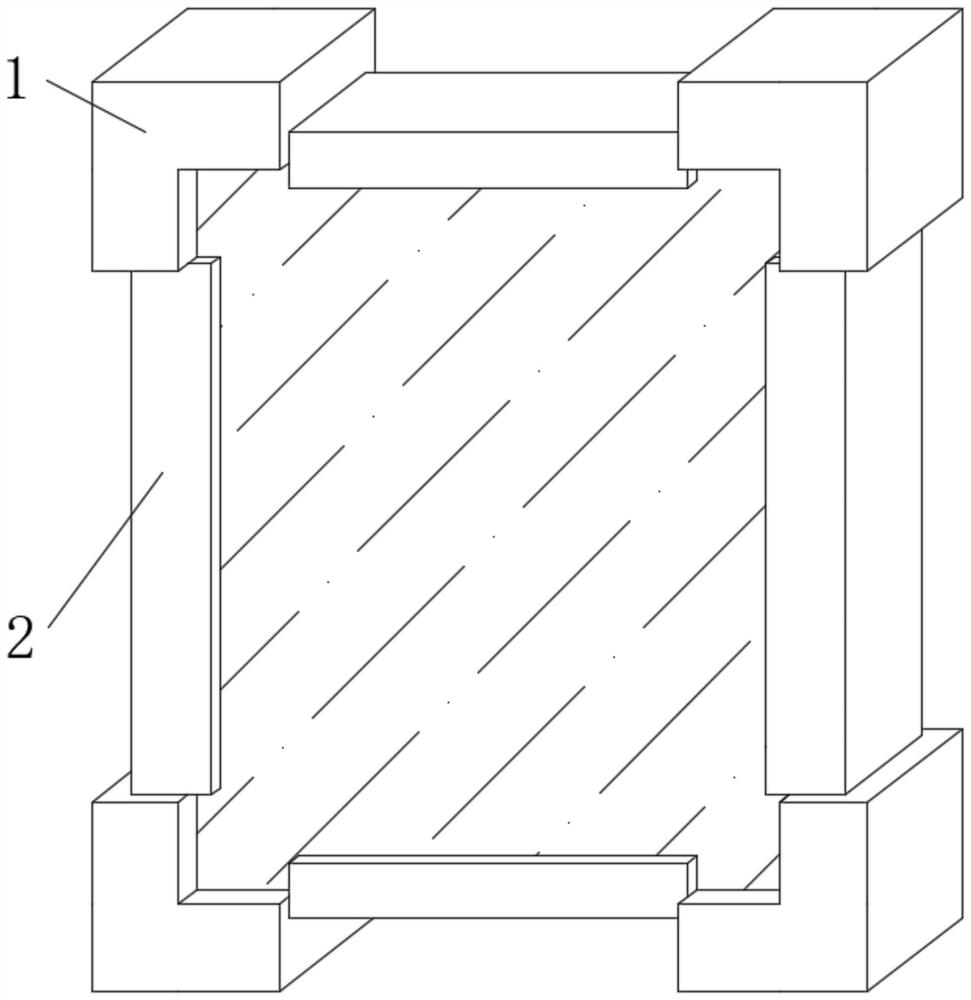

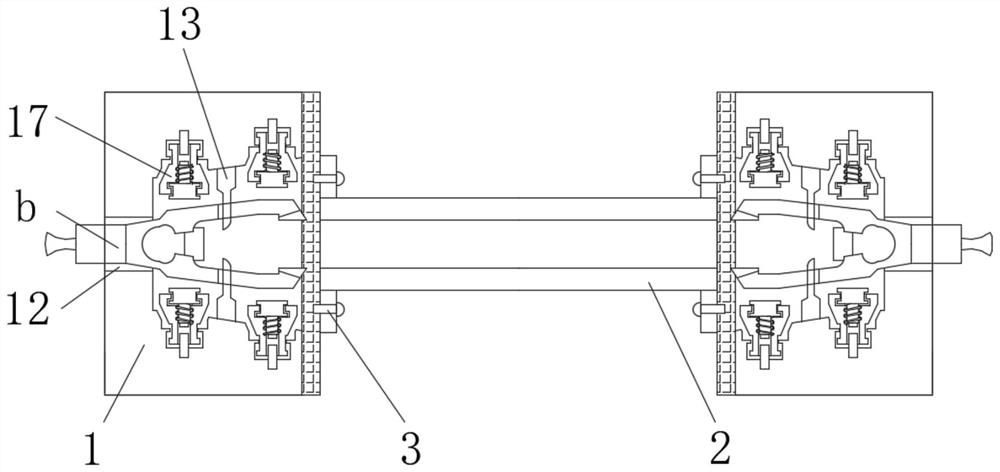

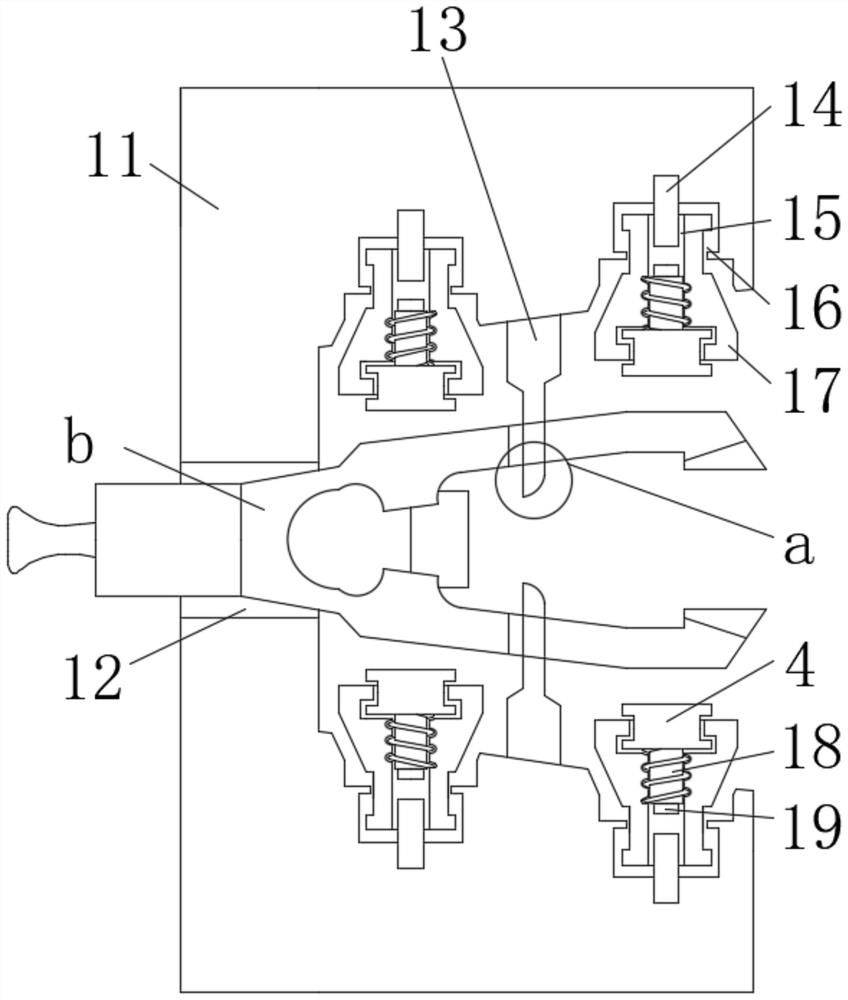

[0030] Such as Figure 1-3 As shown, the present invention provides a technical solution: a glass clamping device for architectural decoration, including a fixing device 1, the number of the fixing devices 1 is four, and the fixing devices 1 are clamped with plastic by side edges. 2 threaded connection, the contact surface between the fixing device 1 and the side clamping plastic 2 is fixedly connected by connecting rivets 3, the fixing device 1 includes a fixing block 11, and the middle of the left surface of the fixing block 11 is opened There is a first through hole 12, a clamping device b is sleeved inside the first through hole 12, a first groove 16 is opened in the depression on the right side of the fixed block 11, and the number of the first groove 16 There are four, and the first grooves 16 are uniformly arranged in the depression on the right side of the fixing block 11 .

[0031]The middle position inside the first groove 16 is fixedly connected with a first magnet...

Embodiment 2

[0034] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the clamping device b includes a shift block b1, the right side of the shift block b1 is fixedly connected with a spring clamp handle b2, and the spring clamp The middle of the right side of the handle b2 is fixedly connected with a cushioning plastic pad b4, and the upper and lower ends of the right side of the spring clamp handle b2 are fixedly connected with a clamping rod b3, and there are four clamping rods b3, and the four clamping rods b3 are evenly arranged At the right end of the spring clamp handle b2, a clamping device 6 is fixedly connected to the end of the clamp rod b3 away from the spring clamp handle b2. The glass is clamped inside the clamping rod b3, and the cushioning plastic pad b4 achieves a protective effect, and the clamping device b is pulled out from the first through hole 12 during the installation process, so that the adsorption dev...

Embodiment 3

[0037] Such as Figure 6-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the ash filter device a includes a collection shell a2, and the top of the collection shell a2 is fixedly connected to the block a1 through a connecting rod The outer surface of the cover block a1 is sleeved in the depression at the bottom of the pre-clamping rod 13, and the inner walls on both sides of the collection shell a2 are respectively fixedly connected with the ash block a3 and the elastic spring a4, and the collection shell The bottom of a2 is slidingly connected with a dust scraping device 5 , and the bottom end of the elastic spring a4 is fixedly connected with the upper surface of the dust scraping device 5 . The ash filtering device a contacts and clamps on the glass under force, and the elastic spring a4 acts as a buffer during the clamping process to prevent the glass from being broken due to excessive force.

[0038] The dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com