Welding method of bending machine rack

A welding method and bending machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of time-consuming and laborious welding and difficult to guarantee welding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

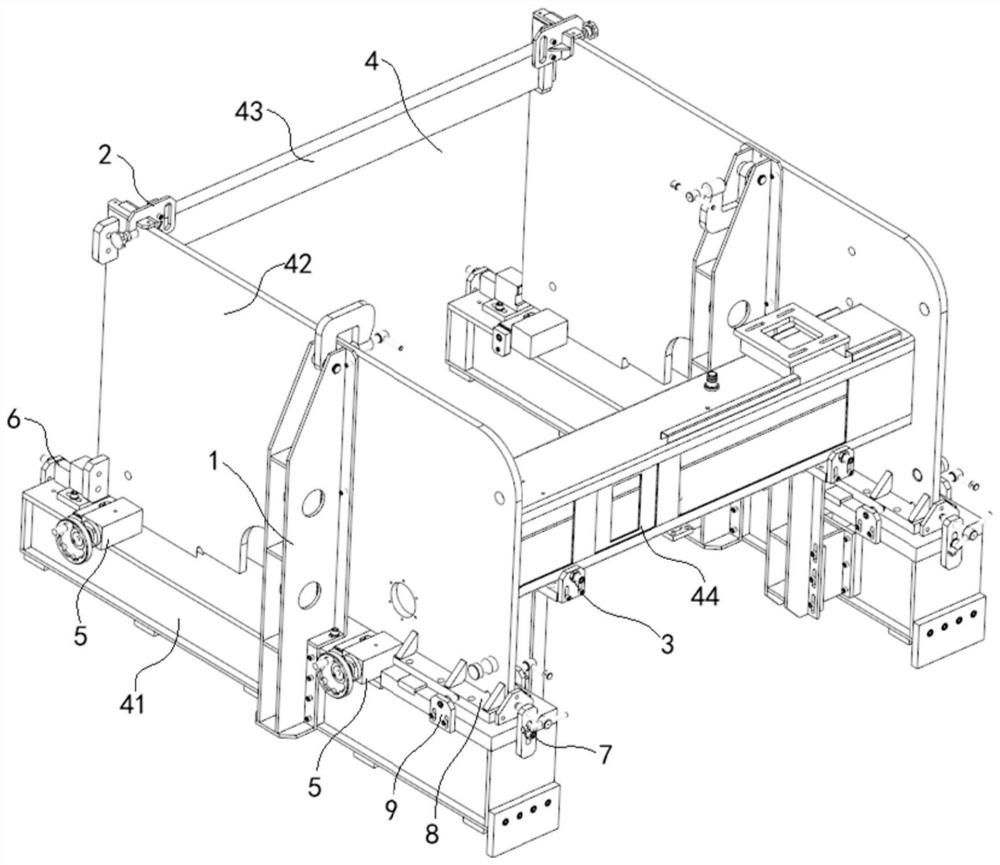

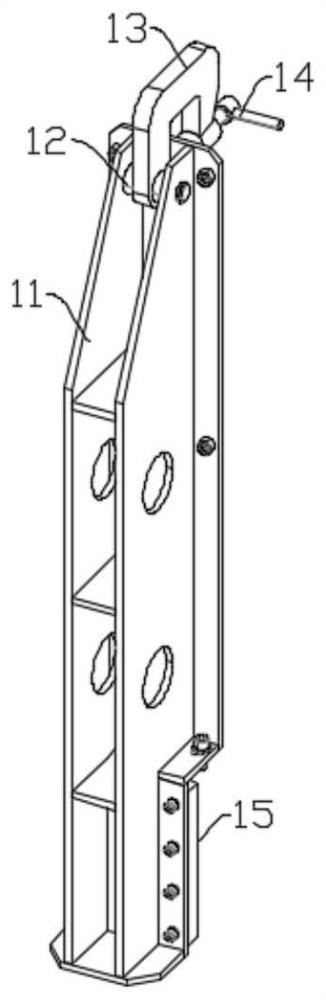

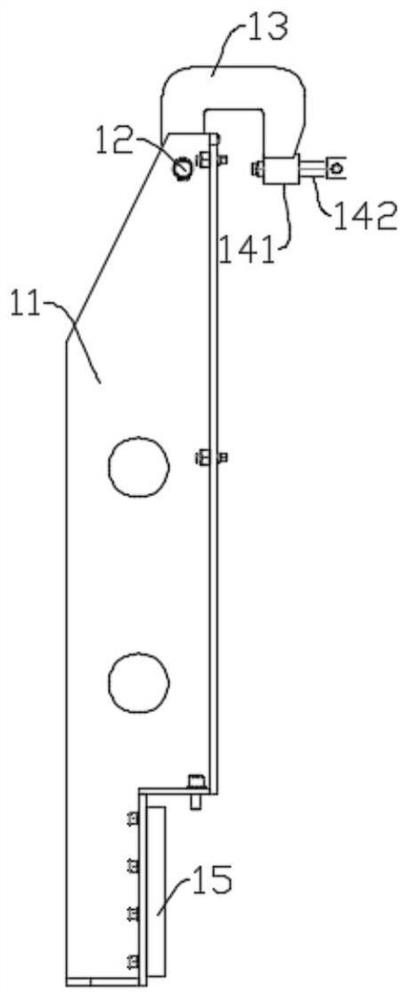

[0067] Such as figure 1 As shown, a bending machine frame welding tool is used to pre-position and fix each component of the bending machine frame, so as to facilitate its welding and improve the welding accuracy of the bending machine frame. Wherein, the bending machine frame 4 mainly includes a pair of bases 41 symmetrically arranged, a pair of wall panels 42 respectively installed on the pair of bases 41 , a pair of wall panels 42 installed between the pair of wall panels 42 and located at the top of the front ends of the wall panels 42 . The front beam 43 and the rear beam 44 installed between a pair of wall panels 42 and positioned at the middle height of the rear ends of the wall panels 42, because the installation positions of the front beam 43 and the rear beam 44, especially the weight of the front beam 44, are quite different. Often the same device cannot be used for fixation.

[0068] The frock mainly includes a first fixing device 1, a second fixing device 2 and a...

Embodiment 2

[0087] A bending machine frame welding method, using a bending machine frame welding tooling in Embodiment 1 to weld each component of the bending machine frame, comprising the following steps:

[0088] 1. After the two bases 41 are placed in parallel, pre-position and fix the wall panel 42 on the base 41 . Wherein, the specific process of pre-positioning and fixing the wallboard 42 on the base 41 is as follows: first, the wallboard positioning plate 8 and the fourth fixing device 5 are fixedly installed on the base 41, and then the wallboard 42 is snapped into the wall The clamping screw 522 and the positioning block 511 on the fourth fixing device 5 pass through the wallboard 42 at the same time. Then, the fifth fixing device 6 and the sixth fixing device 7 are installed on the two ends of the base 41 respectively, and the slider push rod 62 and the pressure block push rod 72 are rotated respectively to control the sliding block 61 and the pressure block 71 from the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com