Heating station for seamless bonding of underwear

A heating table, seamless technology, applied in the field of heating table, can solve the problems that affect the stable product quality of ironing equipment, position deviation, etc., achieve the effects of reducing labor intensity, improving production efficiency, and avoiding positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

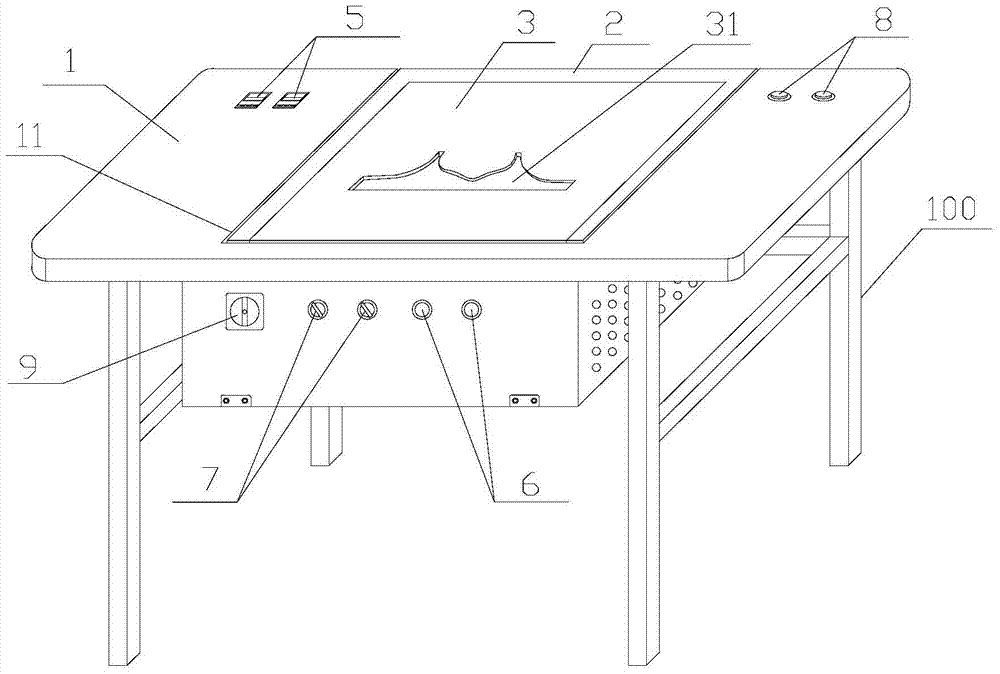

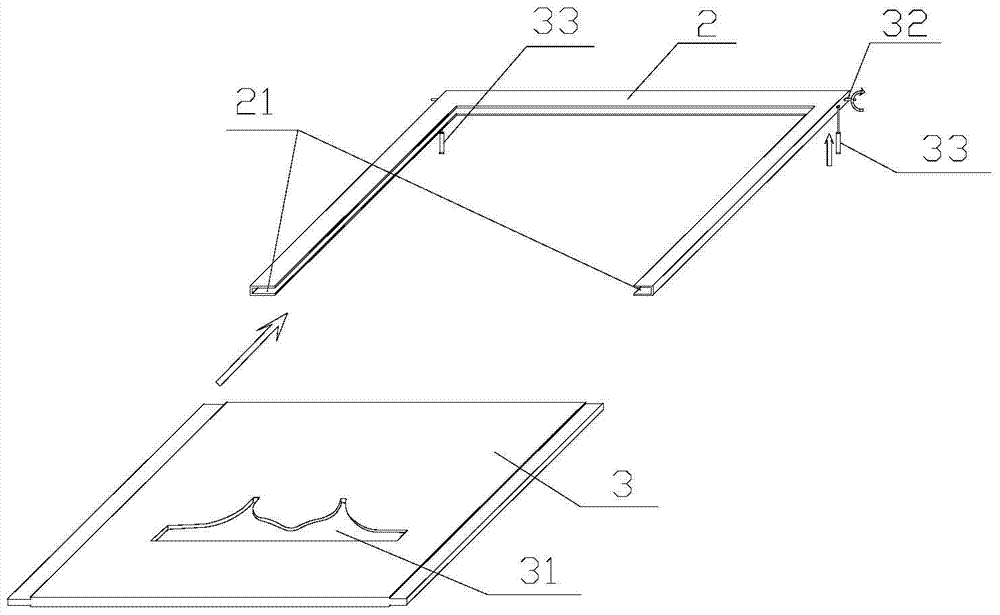

[0021] see figure 1 , a heating table for seamless bonding of underwear, including a machine body 100 with a table top 1 , a heat insulating base 2 , a heat insulating board 3 , a heating device 4 , and a heating plate temperature control device 5 .

[0022] The table top 1 is provided with a hollow opening 11 penetrating up and down, and the heat insulation board 3 is detachably installed in the hollow opening 11 . A hollow groove 31 having the same shape as the cut piece to be heated is opened on the heat insulating board 3 , and the heating device 4 is arranged below the hollow opening 11 .

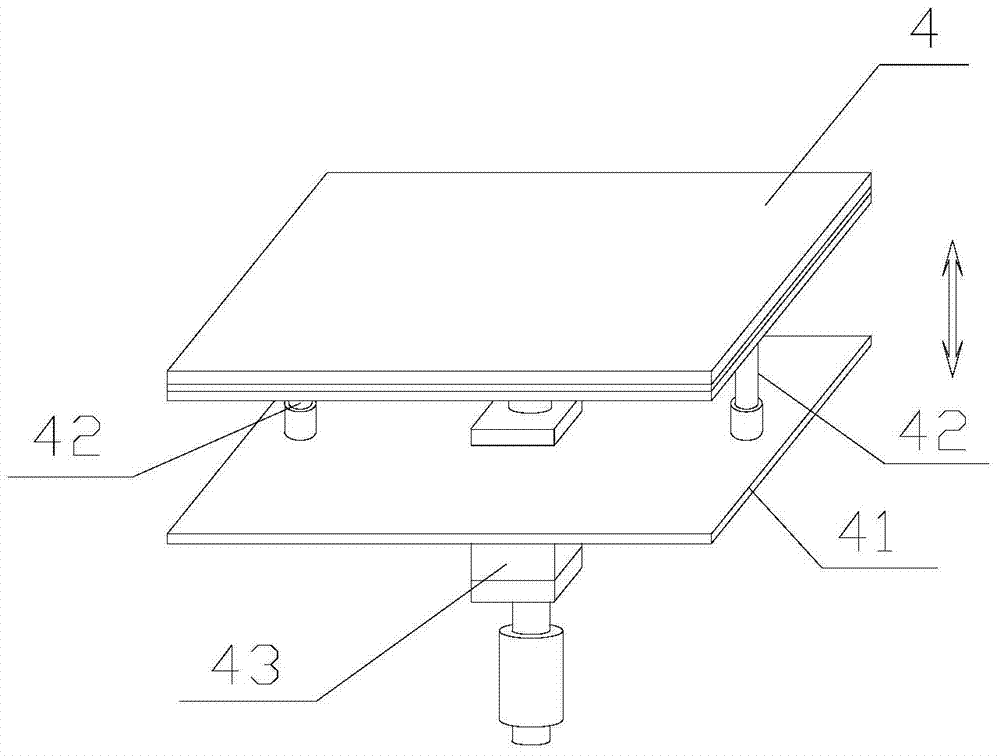

[0023] Such as image 3 As shown, the heating device 4 in this embodiment is a heating plate. The heating plate is arranged below the hollow opening 11 so as to move up and down. A lifting device 43 that drives the heating plate to move up and down is also provided under the table top 1, and the lifting device is an air cylinder or an oil cylinder. Specifically, a fixed plate 41 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com