Hose Connection Device

A hose connection and hose technology, applied in the direction of hose connection devices, pipes/pipe joints/fittings, connections with fluid cut-off devices, etc., can solve the problem of reduced clamping force, vacuum formation cannot always be guaranteed, Does not always reliably prevent problems such as fluid outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

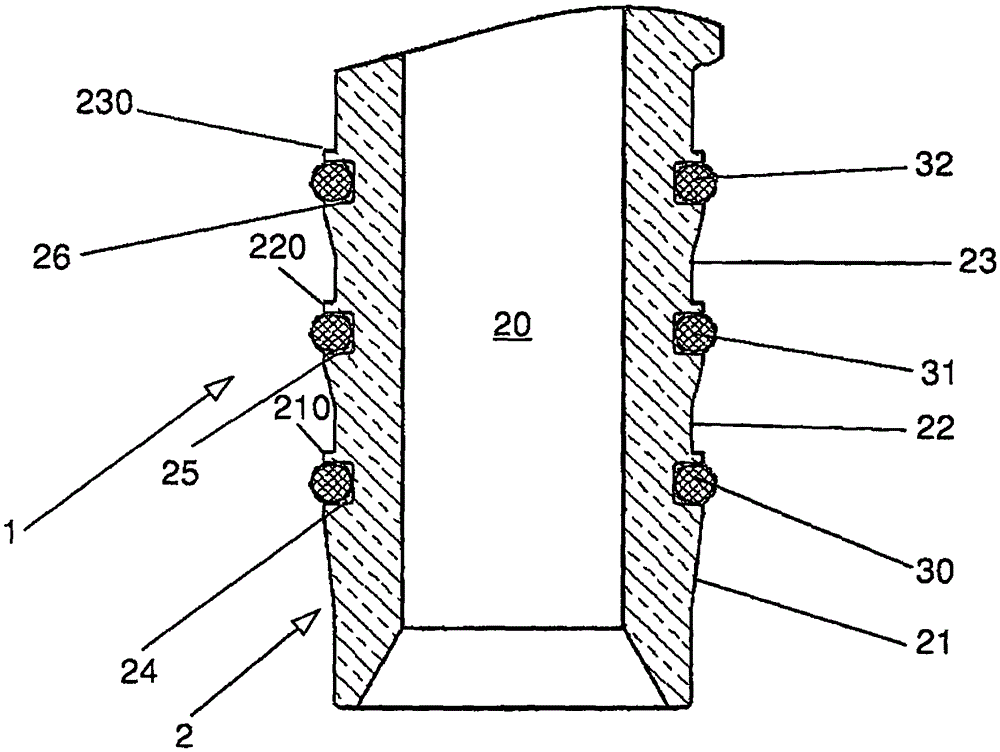

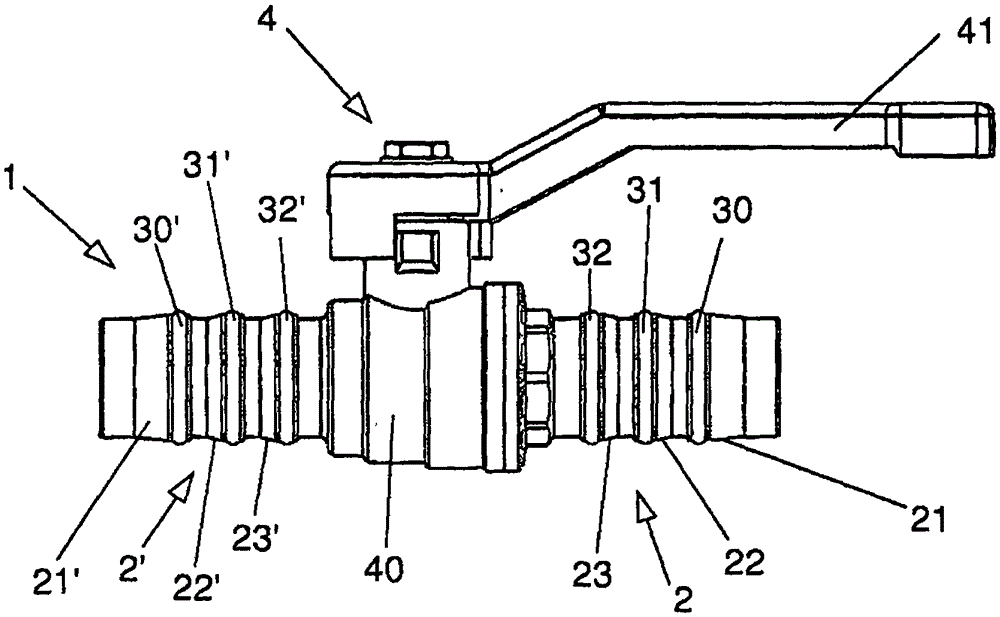

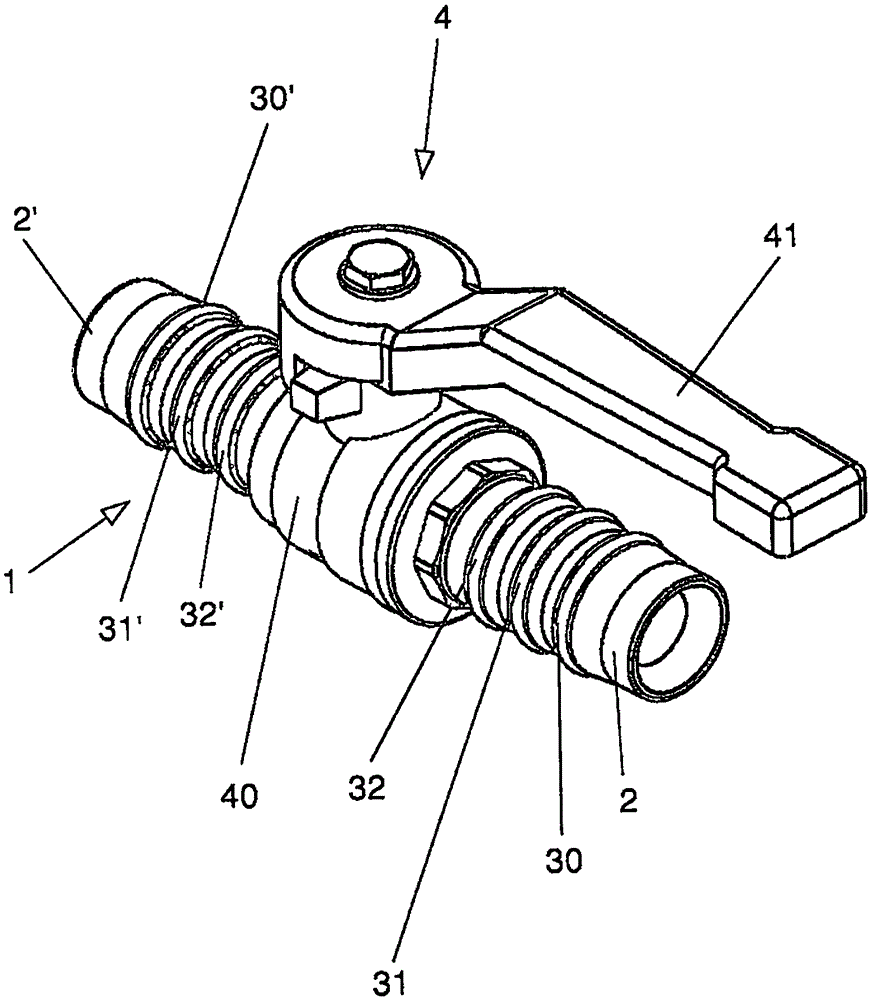

[0021] refer to figure 1 , the hose connection device 1 configured for connecting at least one hose has at least one hollow connection section 2 which has a fluid flow opening 20 inside it, through which a fluid, in particular water, can flow Open your mouth. The connection section 2 is dimensioned and shaped such that a hose can be plugged directly onto it from the outside without a connection adapter or the like. In a manner known per se, viewed in the longitudinal direction, the connecting section 2 has three outer wall sections 21 , 22 , 23 extending in the circumferential direction and having a substantially frustoconical shape. On the rear end of each outer wall section 21 , 22 , 23 viewed in the longitudinal direction, a setback 210 , 220 , 230 is formed from the larger outer diameter to the smaller outer diameter. In other words, the outer wall sections 21 , 22 , 23 have a ribbed structure. The frustoconical shape of the outer wall sections 21 , 22 , 23 in particula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com