Prefabricated stair structure

A staircase and ladder technology, which is applied in the direction of stepped structures, stairs, building structures, etc., can solve the problems of bad sewage dust noise, difficulty in aligning steel bars and fixed pipes, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

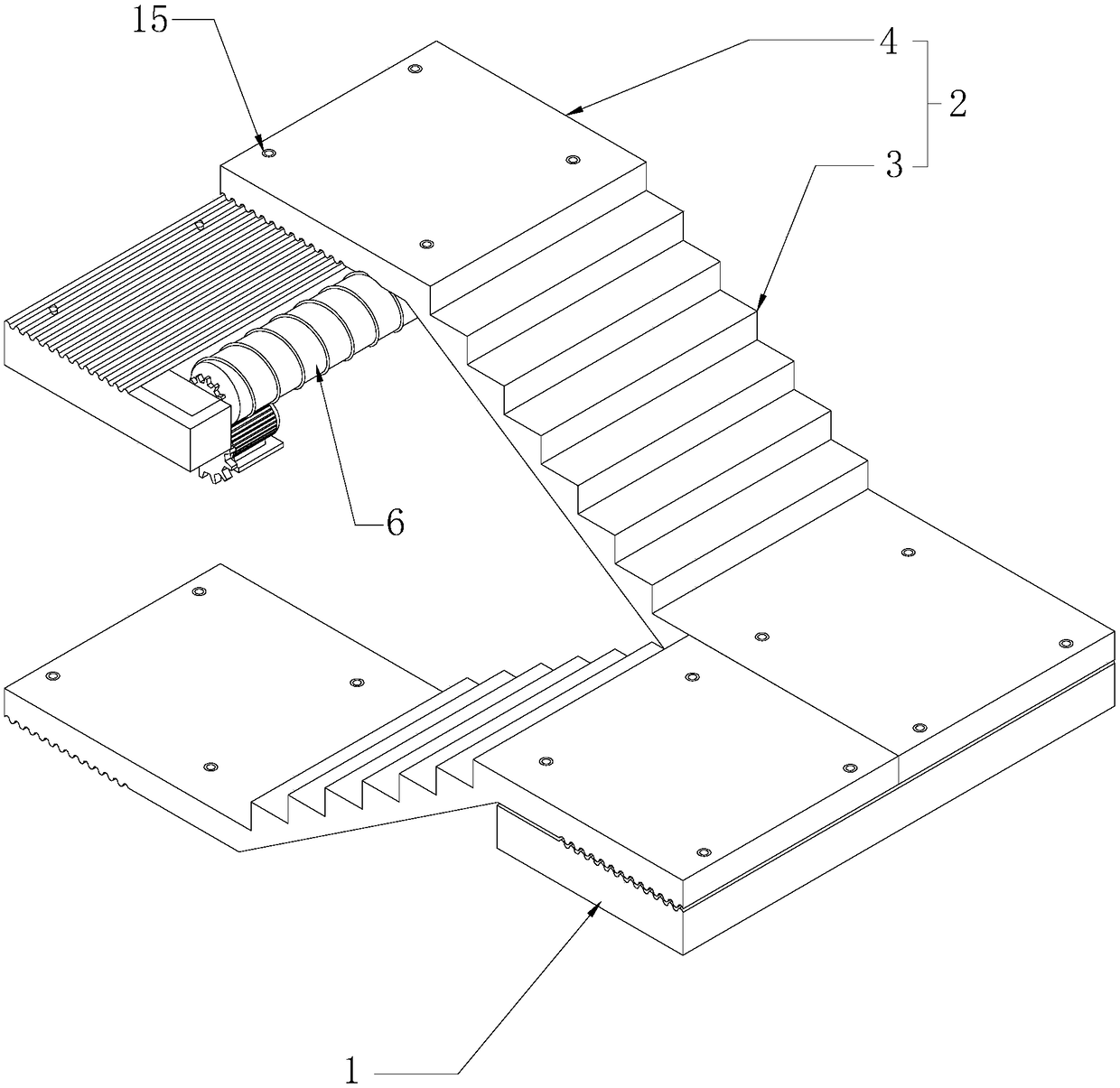

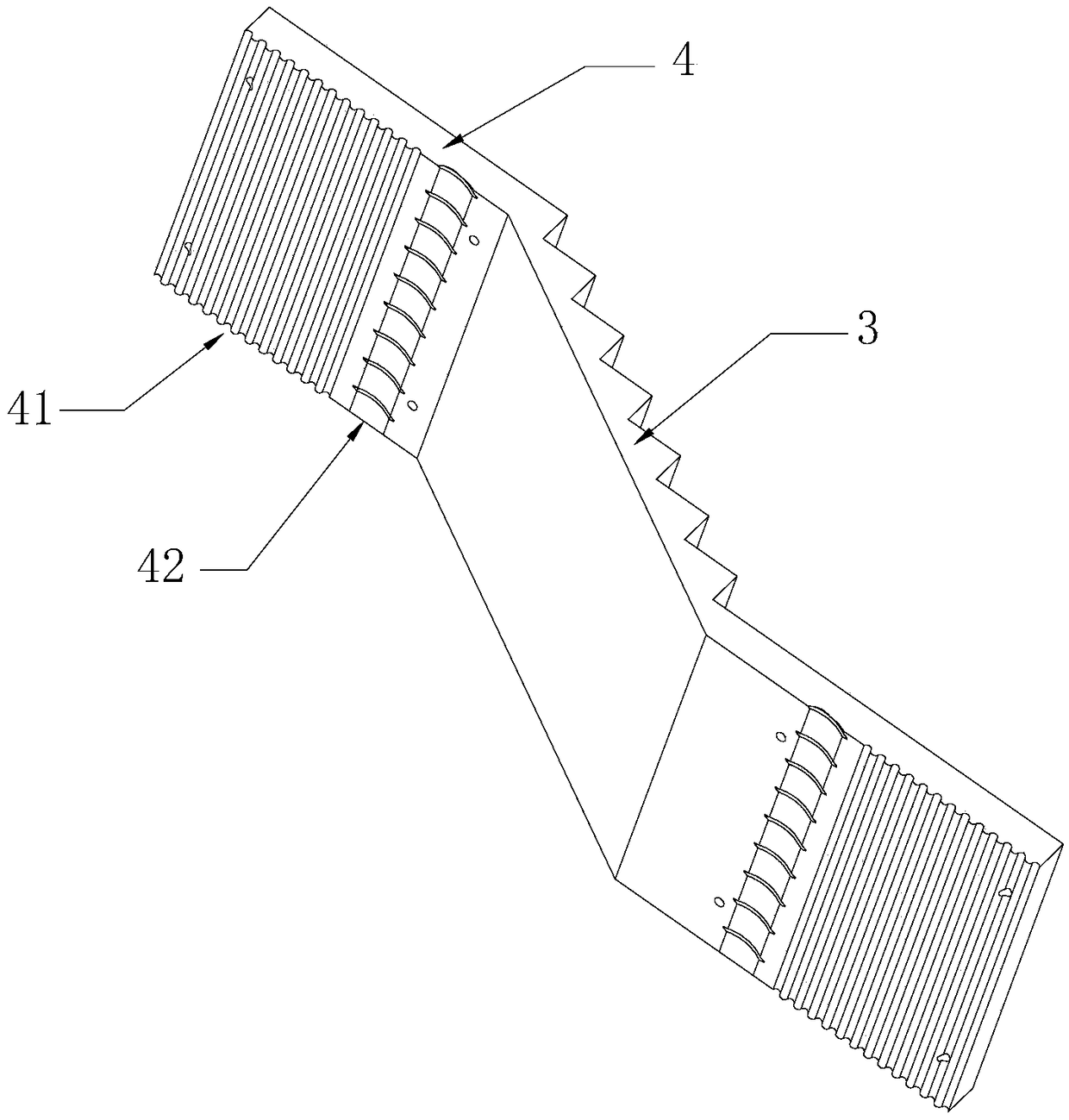

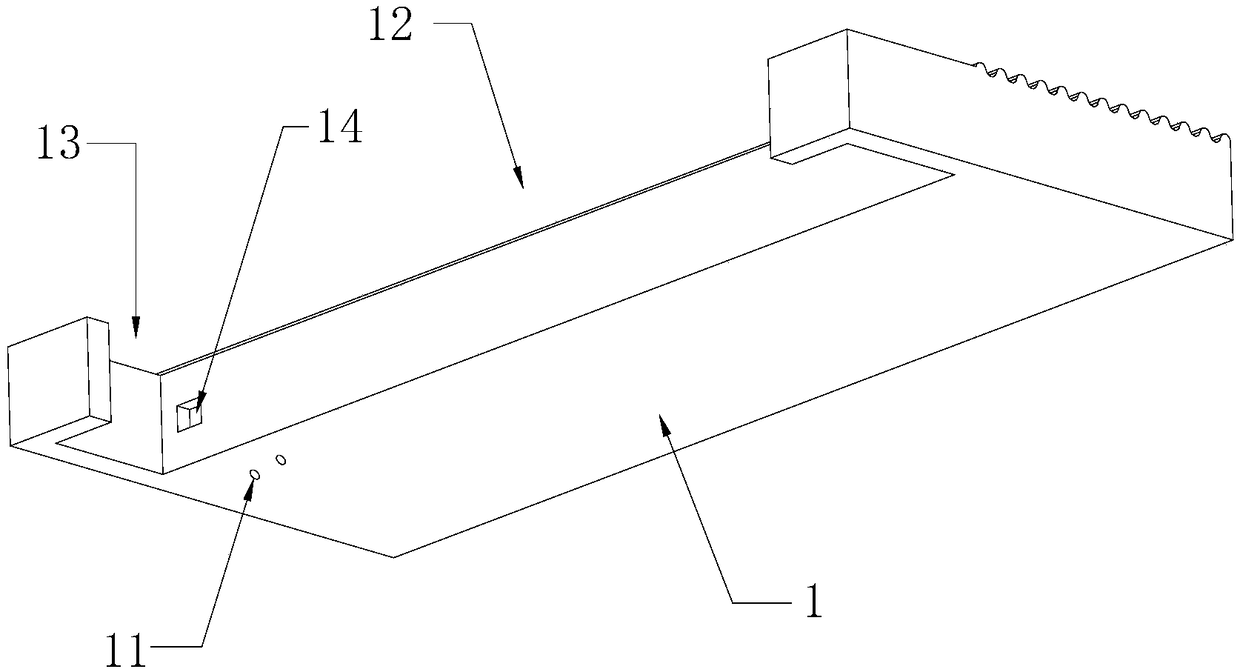

[0032] like figure 1 As shown, a prefabricated staircase structure includes a beam 1 and a staircase 2. The staircase 2 includes a step part 3 and a fixing part 4 located at both ends of the step part 3. The fixing part 4 is erected on the beam 1, and support rollers are arranged on the beam 1. 6. The rotation axis of the support roller 6 extends along the length direction of the beam 1, and a positioning groove 42 for the support roller 6 to be embedded and matched is reserved at the lower end of the fixed part 4, and inserting grooves are provided on the fixed part 4 and the beam 1. Connecting pipe 15, the insertion pipe 15 is arranged along the vertical direction.

[0033] like Figure 4 As shown, when installing the stairs 2, lift the stairs 2, put the stairs 2 (combined figure 2 shown) is erected on the beam 1, the fixed parts 4 at both ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com