Approximate full face excavation structure and methods for mountain highway tunnel in critical stable surrounding rock

A road tunnel, critical stability technology, applied in tunnels, tunnel lining, earthwork drilling and mining, etc., can solve problems such as tunnel construction collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

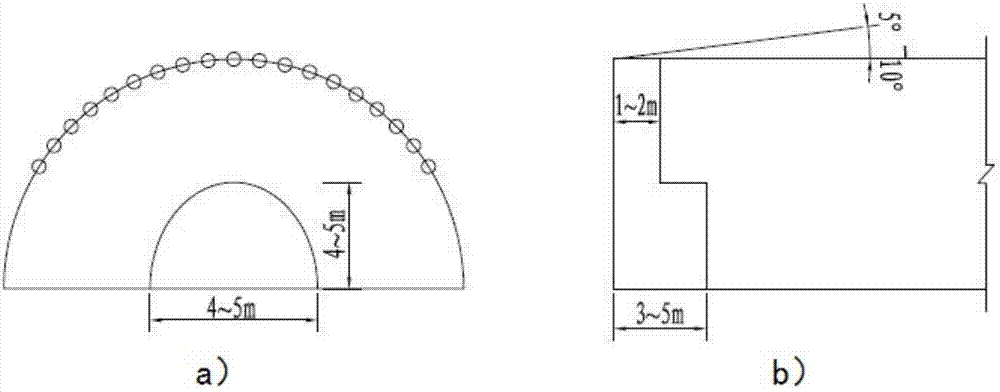

[0031] Such as figure 2 As shown, when the tunnel face is basically stable during tunnel construction, it is advisable to adopt a moderately advanced approach to the full-section construction method of the lower pilot tunnel.

[0032] The face excavation structure of this method is as follows: figure 2 ), along the outer edge of the tunnel contour line, φ108-120mm advanced pipe sheds are built at intervals of 50cm at 2-10° inclination angles in the surrounding rock of the tunnel, and the advanced pipe sheds are filled with cement mortar to form an advanced pre-support structure for the tunnel. A downward pilot tunnel with an arc top is opened on the face of the tunnel within the contour line of the tunnel. The width and height of the excavation plane of the downward pilot tunnel are 4-5m and the longitudinal advance is 3-5m along the excavation direction; the contour line of the tunnel and the downward pilot tunnel The excavation footage of the section clamped between the o...

Embodiment 2

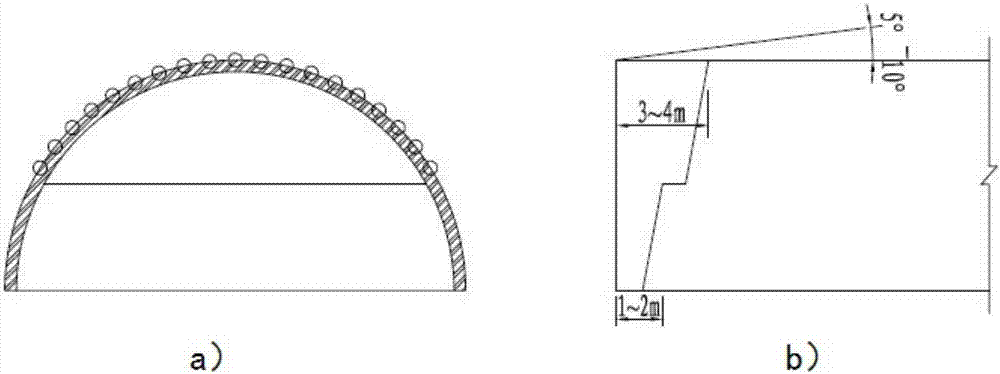

[0040] Such as image 3 As shown, when the face of the tunnel is stable at the boundary during tunnel construction, it is advisable to use short steps to reserve the core soil and approximate the full-section construction method.

[0041] The face excavation structure of this method is as follows: image 3 ) shows that along the outer edge of the tunnel contour line, φ108-120mm advanced pipe sheds are drilled at an interval of 50cm at an inclination angle of 2-10° in the surrounding rock of the tunnel, and the advanced pipe sheds are filled with cement mortar to form an advanced pre-support structure for the tunnel; There are inclined upper and lower steps on the face of the tunnel within the contour line. The upper step is 1-3m ahead of the lower step, and the core soil is reserved for both the upper and lower steps; the excavated tunnel is provided with initial support to bear all Surrounding rock load.

[0042] The construction steps of the approximate full-section constr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com