Rock breaking multi-arm cantilever tunneling machine carried with suspension cutters and method for constructing rock breaking multi-arm cantilever tunneling machine

A technology of cantilever roadheader and cutting knife, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., and can solve problems such as difficult excavation of special-shaped tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

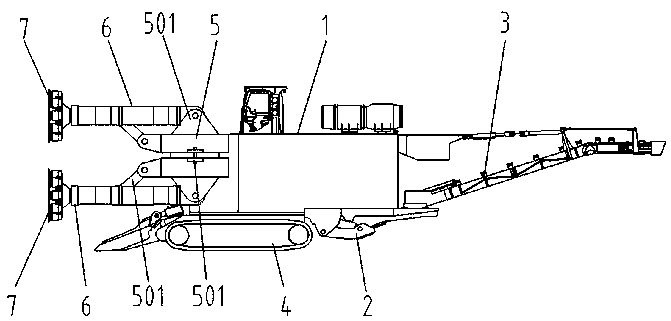

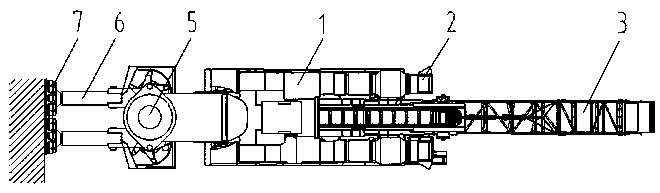

[0033] Embodiment 2: A multi-arm type cantilever roadheader equipped with a suspension cutter for rock breaking, the two rotary tables 5 are connected by bearings, such as figure 2 As shown, two booms 6 are hinged on each turntable 5 , and each boom 6 is hinged to two pitch cylinders 503 . It is convenient for the cantilever 6 to move up and down and rotate stably and uniformly, to increase the bearing capacity of the cantilever 6, and to carry out unified and coordinated rock breaking on the face of the tunnel. Other structures and usage methods are the same as those in Example 1.

Embodiment 3

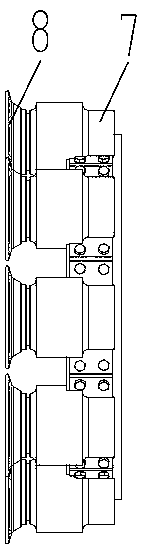

[0034] Embodiment 3: A multi-arm type cantilever roadheader equipped with a suspension cutter to break rock, in order to make the suspension cutter 8 easy to bear force when breaking rock, as Figure 4 As shown, the edge of the upper part of the hanging cutter 8 extends out of the edge of the cutter head 7, and the lower part of the hanging cutter 8 is fixed on the cutter head 7 by bolts. Other structures and usage methods are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com