Ultralow surface full-hydraulic drill type coal mining machine

A fully hydraulic, shearer technology, used in earth-moving drilling, rotary drilling rigs, cutting machines, etc., can solve the problems of equipment slippage, low power of coal plows, and low operating reliability, and reduce the cost of excavation. The effect of reducing the height of the whole machine and reducing the cost of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

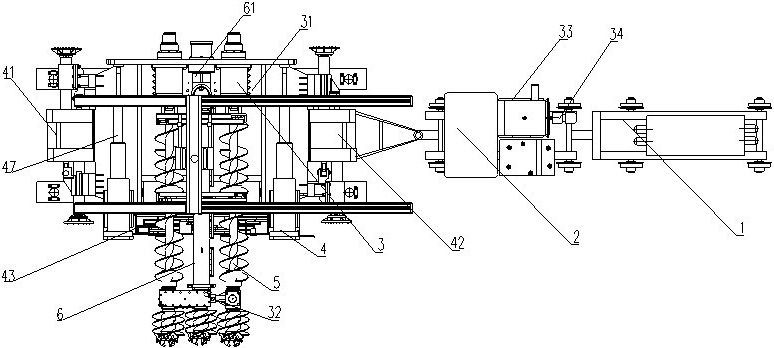

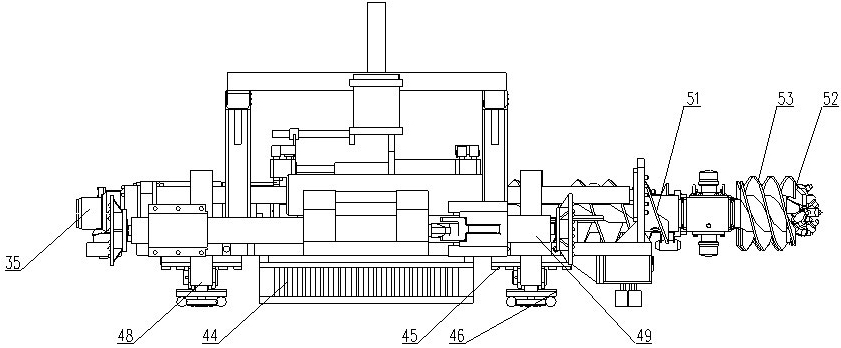

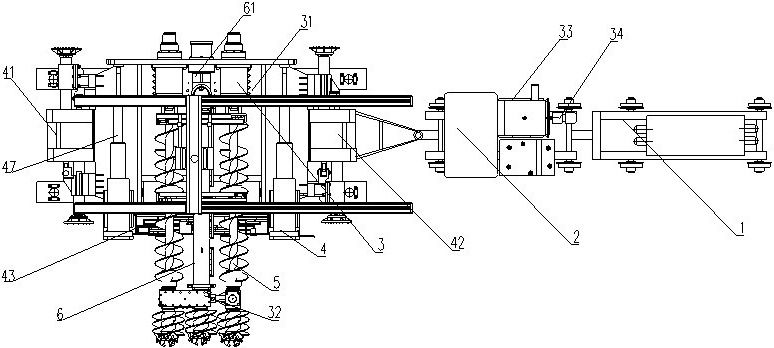

[0015] Such as figure 1 and figure 2 As shown, the present invention includes an electric control assembly 1, a hydraulic assembly 2, a drilling tool assembly 5 and a ventilation device 6, and also includes a transmission device 3 and a frame 4, and the transmission device 3 includes a driving frame 31, a front moving box 32, Motor 33, duplex plunger pump 34, driving motor 35, motor 33 is connected to driving motor 35 through duplex plunger pump 34, driving motor 35 is connected front moving box 32 through output shaft, front moving box 32 is connected drill bit 52, driving motor 35 is two and is installed on the driving frame 31, frame 4 comprises left side frame 41, right side frame 42, front frame 43 and connecting beam 44, left side frame 41 and right side frame 42 are connected with connecting beam 44 by high-strength bolts Connection, the front frame 43 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com