Medium-length hole blasting and cutting method in underground construction

A deep hole blasting and underground engineering technology, applied in blasting and other directions, can solve the problem of low blasting efficiency and achieve good blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The invention provides a deep hole blasting cutting method in underground engineering, the specific technical scheme is as follows:

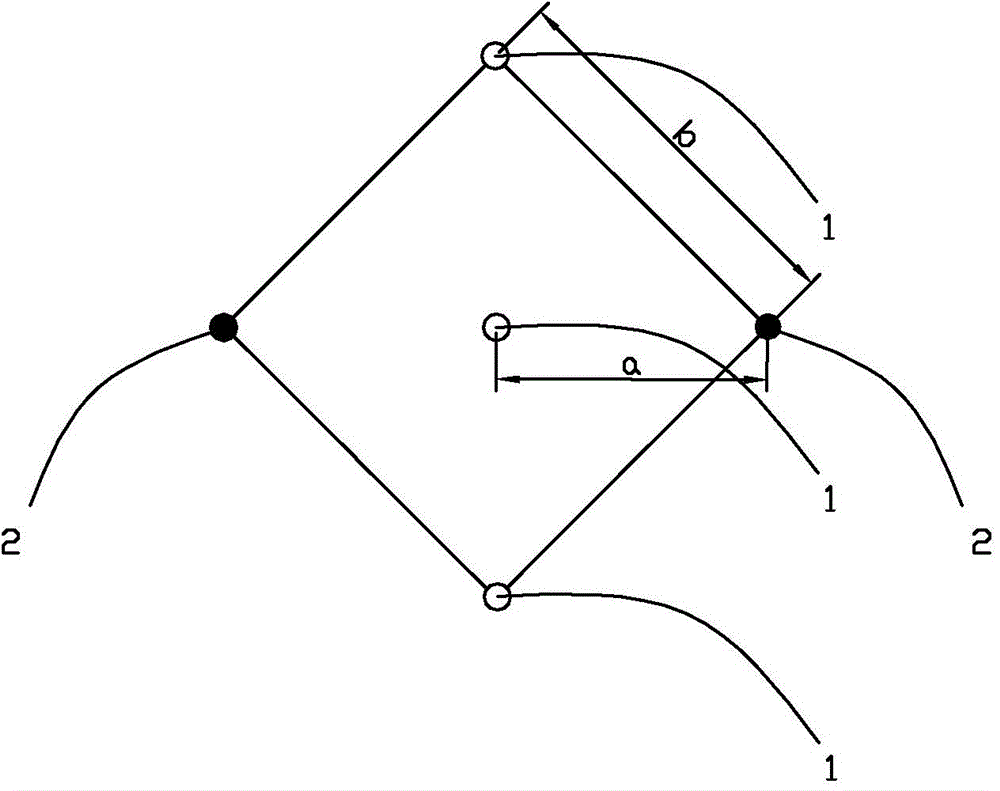

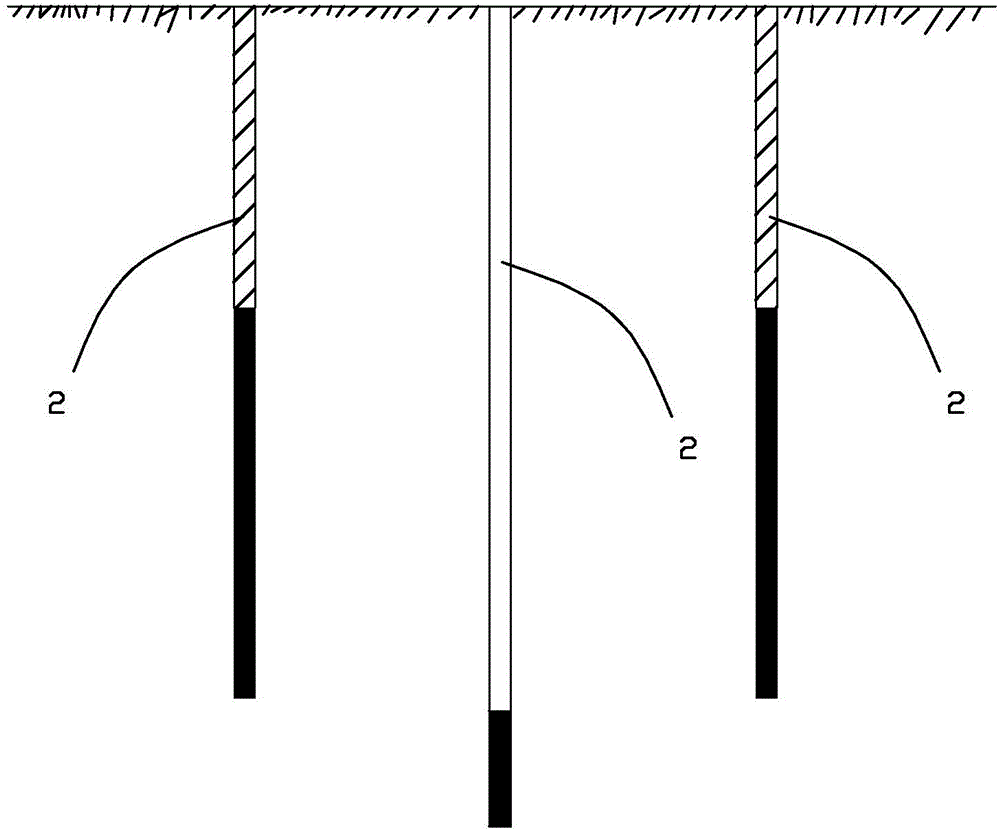

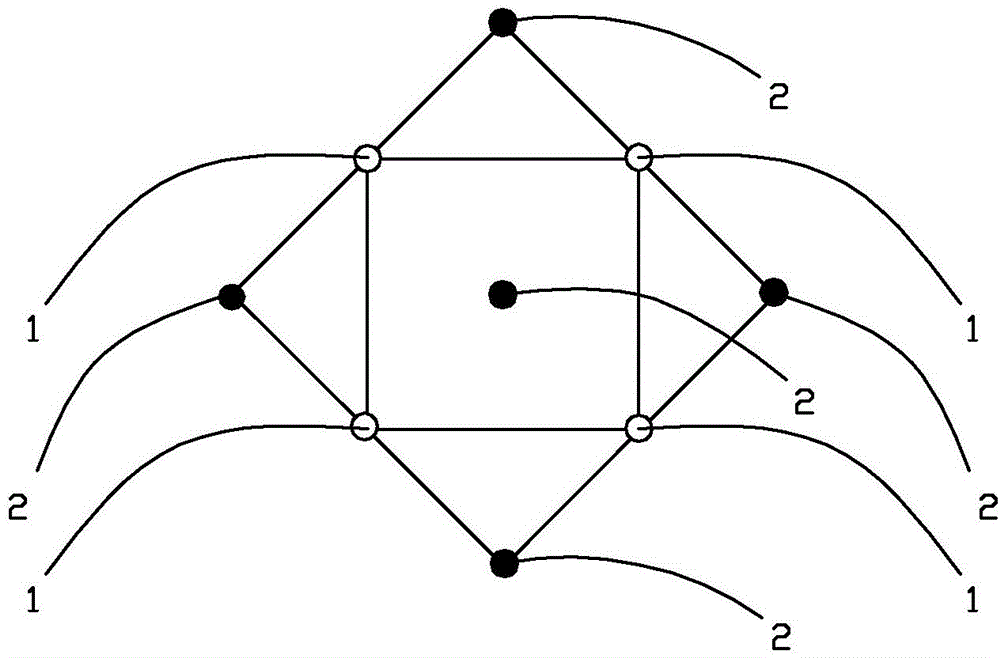

[0025] The deep hole blasting in underground engineering adopts the straight hole cutting method. The continuous columnar charge of the cut blast hole 2 is divided into two parts, the upper columnar charge breaks the rock, forms a weak throw, and produces a blasting funnel, while the lower columnar charge produces a crushing and crushing effect, and only a very small amount of energy is used for the rock of the throw.

[0026] According to this, the spacing z of the blast hole 2 can be calculated by the following formula: z=φ(p 1 / p c ) 1 / β , where φ is the charge diameter; β is the attenuation index, μ is Poisson's ratio of rock; p 1 is the explosion pressure on the 2 wall of the cutting blast hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com