Mining method of layering and non-segmented roadway filling in downward approach of broken surrounding rock ore body

A technology of crushing surrounding rock and filling mining, which is applied in underground mining, filling, ground mining, etc., can solve the problem of less research on roadway support technology for metal ore crushing surrounding rock, which is unfavorable for the sustainable development of mine economy and consumes a lot of manpower , material resources and other issues, to achieve the effect of reducing the cost of mining equipment, simplifying the layout of mining tunnels, and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

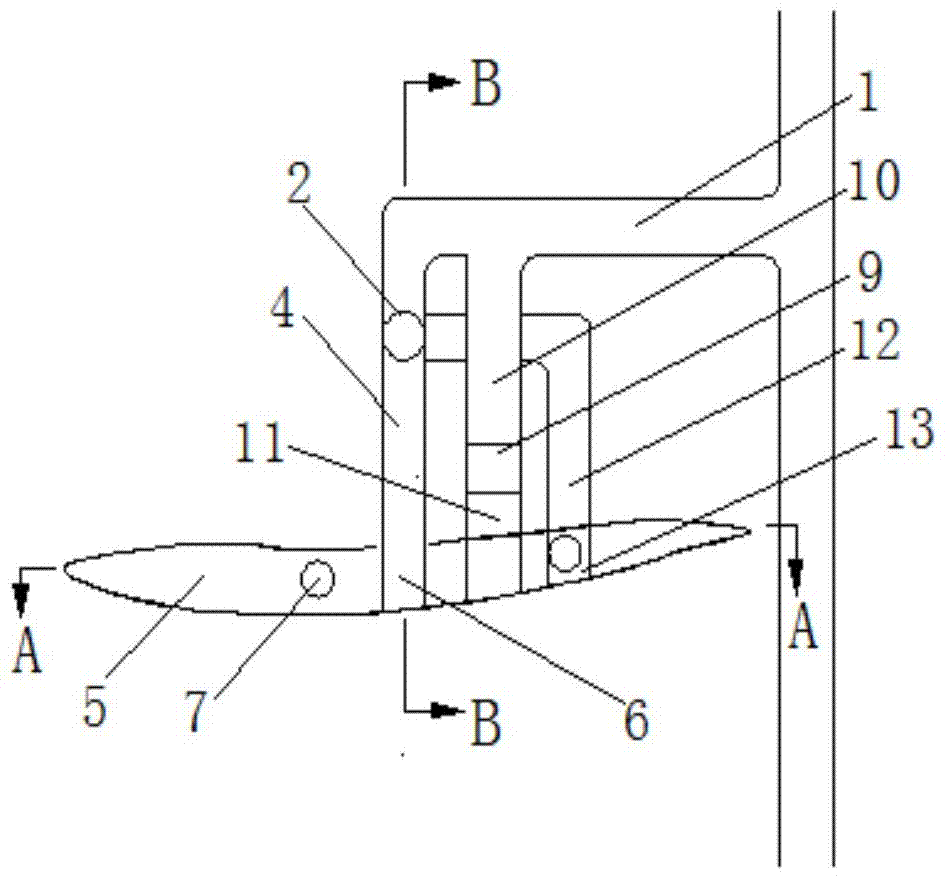

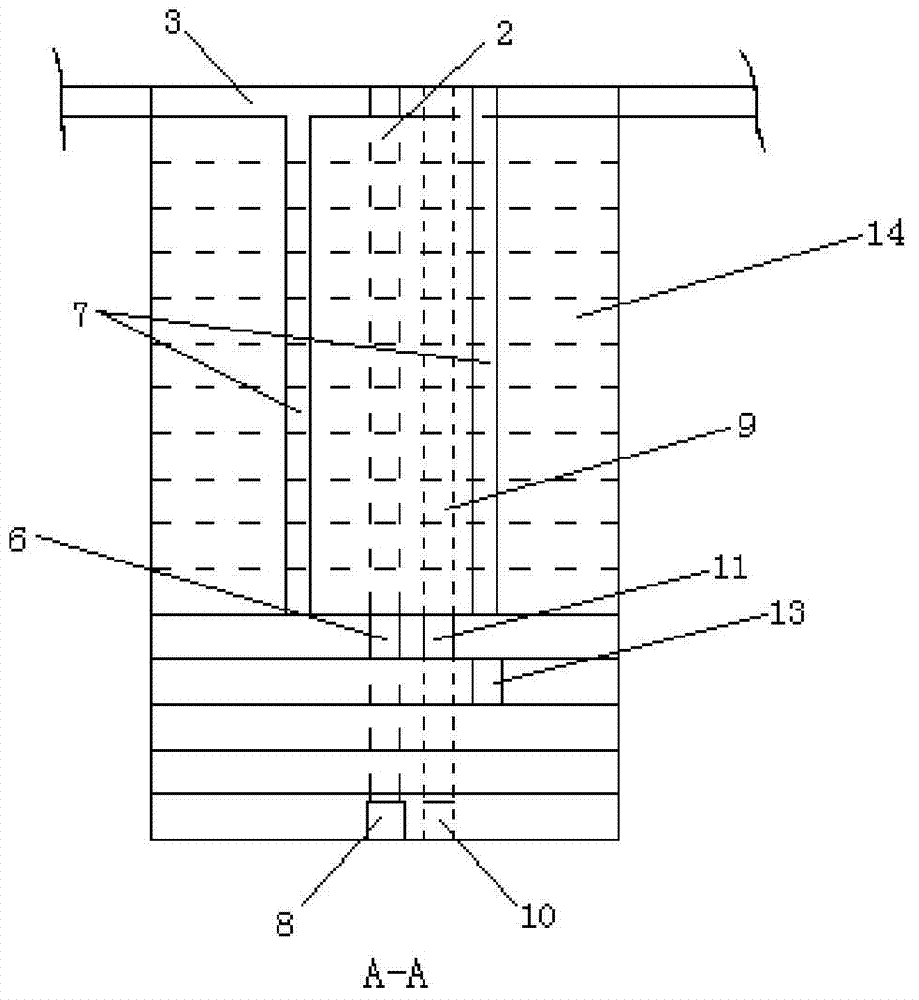

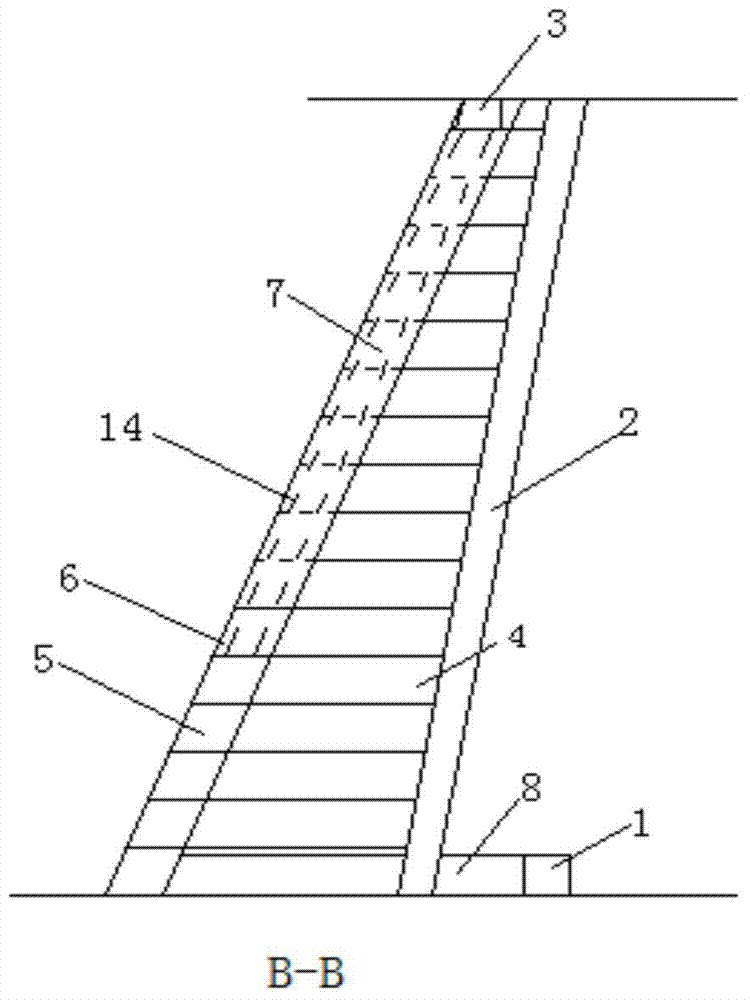

[0030] The stope layout of the mine method for layering and non-segmented roadway filling in the downward approach of the broken surrounding rock ore body of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1 to Figure 3 As shown, the broken surrounding rock ore body of the present invention has a downward approach layered non-section roadway filling mining method, and its corresponding broken surrounding rock ore body stope arrangement is as follows: stope main transport lane 1, slip shaft 2, along the vein Air return lane 3, chute connection road 4, ore body 5, layered level roadway 6, filling-return air shaft 7, vein-piercing transport road 8, pedestrian ventilation patio 9, vein-piercing air inlet duct 10, cutting level lane 11, The lower layer chute connecting road 12, the lower layer drift 13, and the overlying filling body 14.

[0032] Below, taking a gold mine as an example, the mining meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com