Rock breaking tunneling machine using liquid nitrogen and jet of ice particles

A roadheader and liquid nitrogen technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problem of abnormal wear and replacement frequency of disc hobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

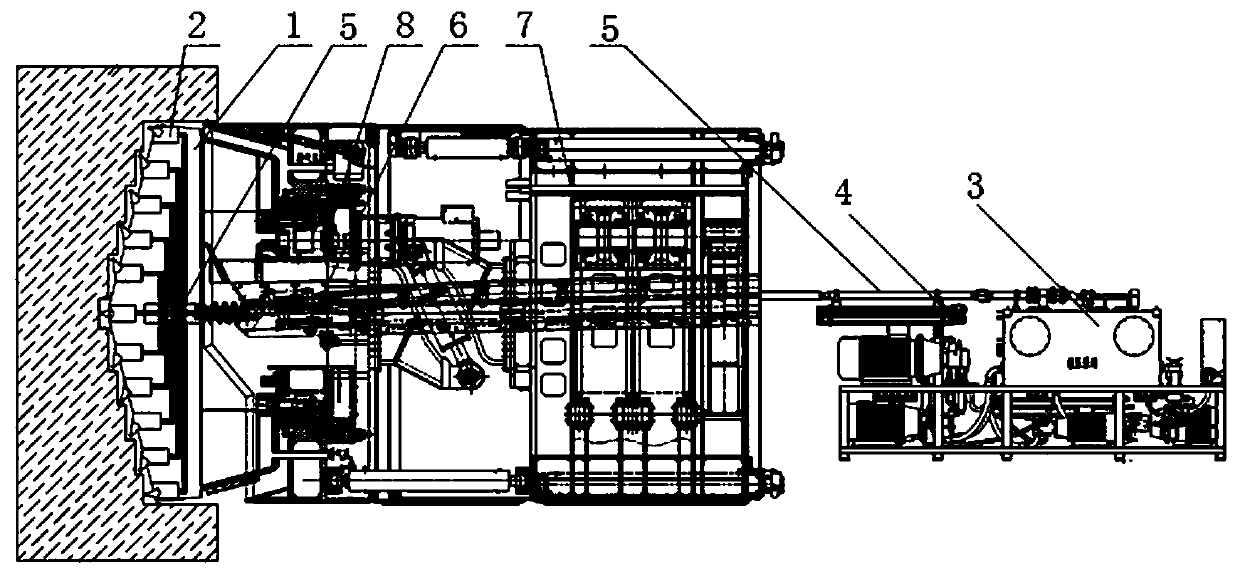

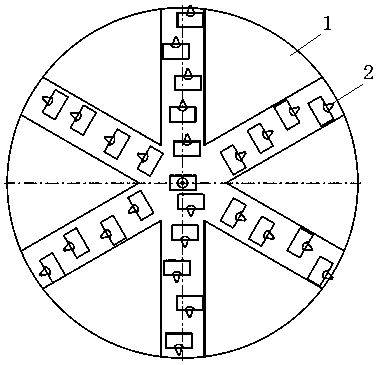

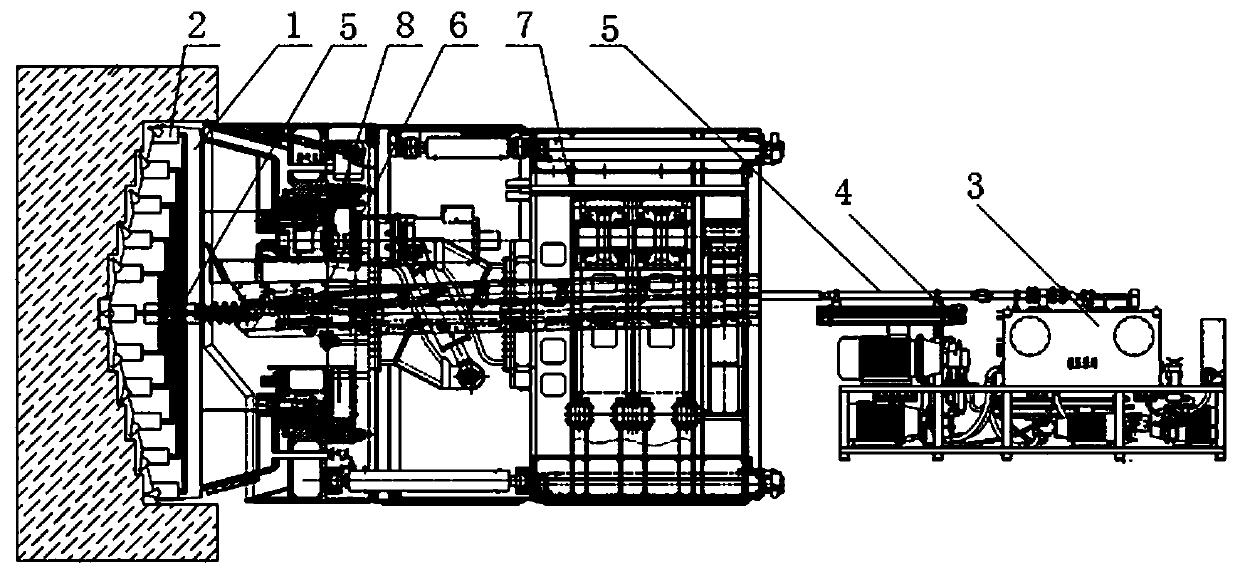

[0016] Embodiment 1, a kind of tunneling machine utilizing liquid nitrogen and ice particle jet to break rock, such as figure 1 and figure 2 As shown, a cutter head system 1 is included, and a liquid nitrogen ejection nozzle 2 is arranged on the cutter head system 1 , and the liquid nitrogen ejection nozzle 2 is connected to a liquid nitrogen generator 3 through a high-pressure pipeline 5 . The liquid nitrogen generating device 3 can generate liquid nitrogen, and the liquid nitrogen generating device 3 can transport the generated liquid nitrogen to the liquid nitrogen emission nozzle 2 through the high-pressure pipeline 5, and the liquid nitrogen emission nozzle 2 can eject the liquid nitrogen at a super high speed, A jet beam with highly concentrated energy is formed. This jet beam has the impact of water jet, freezing force destruction function and thermal destruction function, and can break rocks to realize tunneling.

[0017] An ice particle production device is arranged...

Embodiment 2

[0020] Embodiment 2, a roadheader using liquid nitrogen and ice particle jet to break rock, the liquid nitrogen injection nozzle 2, high-pressure pump station 4, negative pressure device and ice particle production device are all connected to the control system. The control system can remotely adjust the output pressure of the high-pressure pump station 4, control the opening and closing of the liquid nitrogen injection nozzle 2, control the production and transportation of ice particles, and then can conveniently adjust the volume of liquid nitrogen injected by the liquid nitrogen injection nozzle 2 according to different geology. pressure.

[0021] Other structures of this embodiment may be the same as Embodiment 1.

Embodiment 3

[0022] Embodiment 3, a roadheader that uses liquid nitrogen and ice particle jets to break rocks. A pressure gauge is provided on the high-pressure pipeline 5 between the high-pressure pump station 4 and the liquid nitrogen injection nozzle 2, which can be monitored in real time according to the pressure gauge. The pressure of the ejected liquid nitrogen can be adjusted in real time through the high-pressure pump station 4 .

[0023] Other structures of this embodiment may be the same as those of Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com