Waste filling thin coal seam tunnelling method

A technology of thin coal seam and gangue, which is applied to the field of relatively hard roof and floor, can solve the problems of high gangue extraction rate and low coal output rate in tunneling, reduce the rate of gangue per ton of coal, increase the amount of coal output during tunneling, and reduce the environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

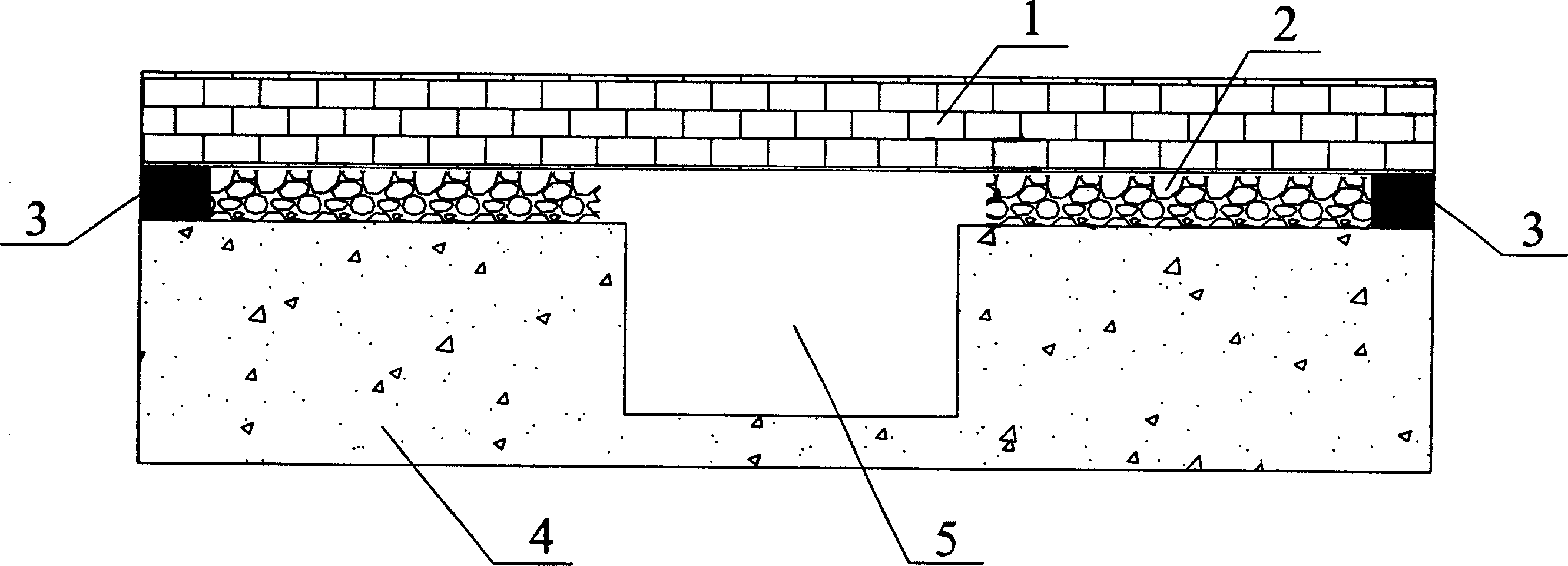

[0008] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0009] As shown in the accompanying drawings, after excavating the section of the roadway 5 that meets the formal production requirements, a certain length of coal seam is excavated along the thin coal seam 3 on both sides of the roadway 5. The specifications of the roadway 5 are generally: the width is about 2.5m, the thickness The height of the coal seam floor 4 from the thin coal seam roof 1 can reach about 1.8m, and the coal body length of the thin coal seam 3 extracted by the left and right sides can reach about 10m at most. Adhere to the shallow eye, less charge, improve the quality of the roadway. The mined coal body space is filled and reinforced with gangue excavated from the roadway, and when necessary, the filled gangue layer 2 is grouted to make it tightly in contact with the coal seam roof 1 and coal seam floor 4 to ensure that the roadway m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com