Coal mining method of lengthened front-beam fully-mechanized mining and fully-mechanized top coal carving of three-soft coal seam and equipment

A technology of three soft coal seams and coal mining methods, applied in mining equipment, ground mining, earth square drilling and mining, etc., can solve problems such as hindering the penetration and diffusion of Marisan, coal cannot be bonded into one body, and restricting safe production at the mining face. It achieves the effects of being beneficial to gas management, reducing the amount of bottom drilling, and having a large cover space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

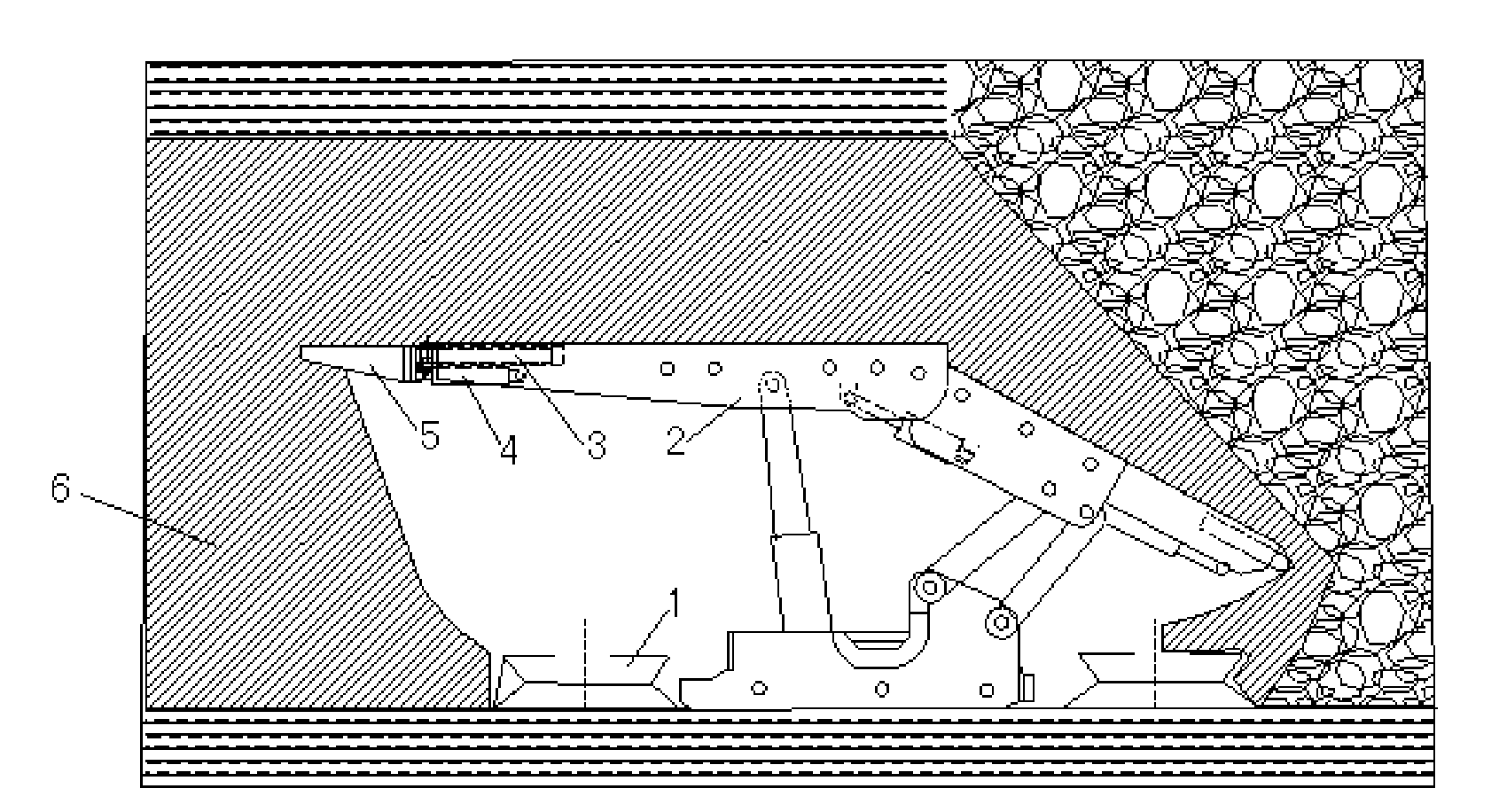

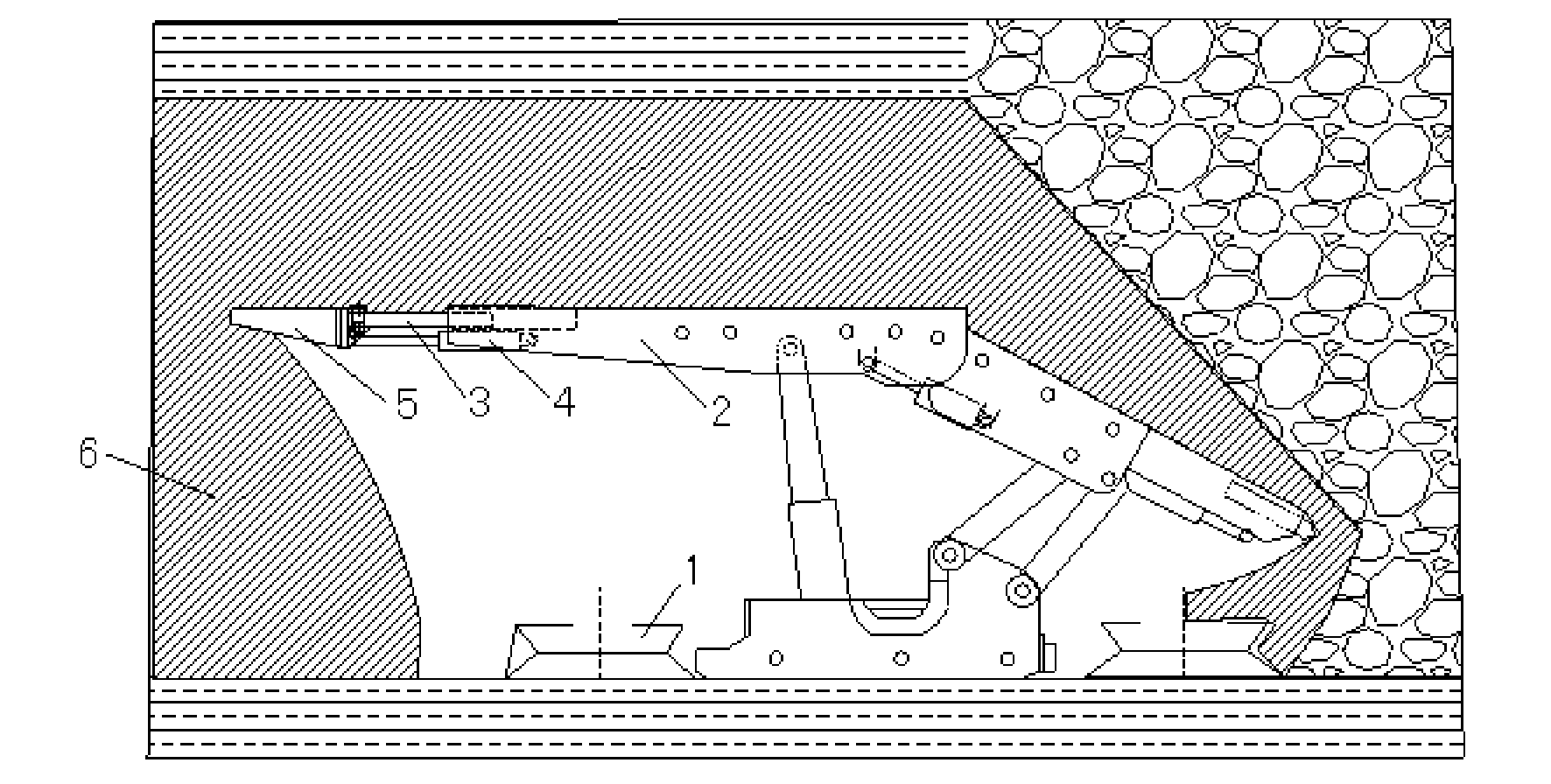

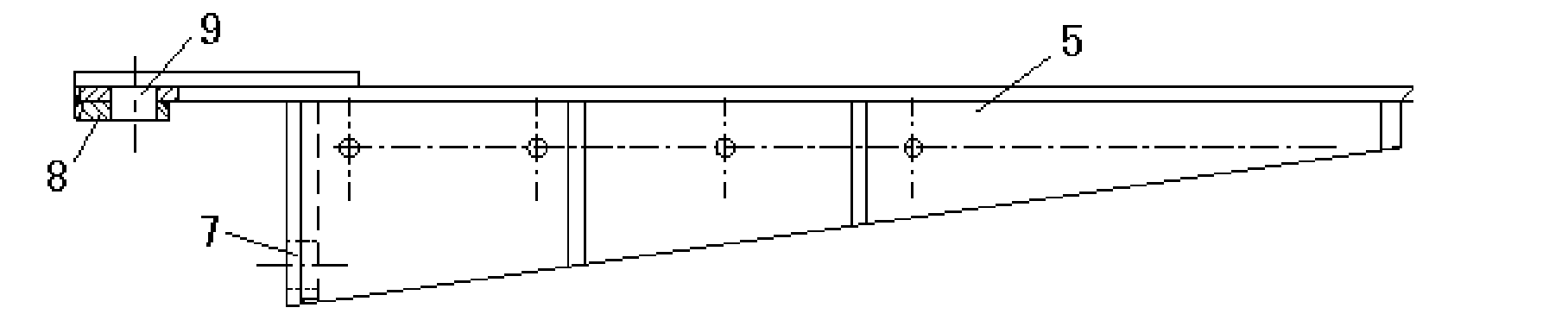

[0019] Example 1. Such as figure 1 As shown, the coal mining equipment includes a coal mining machine, a scraper conveyor 1 and a hydraulic support 2, and the front end of the hydraulic support 2 is equipped with a telescopic front beam 3 and a telescopic front beam hydraulic cylinder 4, and the telescopic front beam 3 and the telescopic front beam hydraulic pressure Oil cylinder 4 is connected by pin, and lengthening front beam 5 is installed on the front end of telescopic front beam 3, and lengthening front beam 5 is fixedly connected on telescopic front beam 3 by bolts. The shape of lengthening front beam 5 is as image 3 As shown, its width is the width of the telescopic front beam 3, and the length will be different according to the softness of the coal seam, the mining height and the depth of the sheet side. It is 1.2 to 1.6 meters. The fixing of elongated front beam 5 at telescopic front beam 3 beam ends is key of the present invention. When processing and welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com