Method for encapsulating and manufacturing glue perfusion molded SIM (subscriber identity module) film card with flip naked chip

A manufacturing method and bare chip technology, which is applied in semiconductor/solid-state device manufacturing, record carriers used by machines, instruments, etc., can solve the problems of increasing product molding thickness, chip pin and chip damage, and difficulty in controlling production efficiency. To achieve the effect of improving the stress condition, stable quality and improving thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

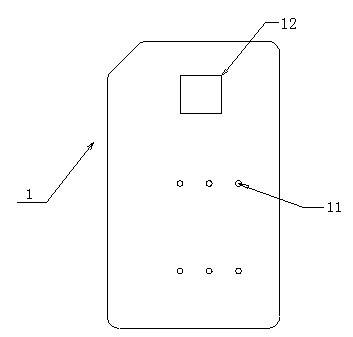

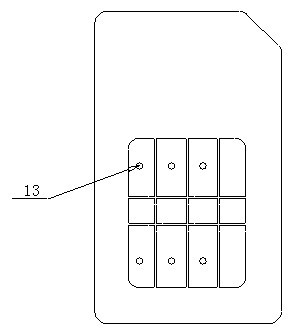

[0045] Processing and production of a SIM film card flexible circuit board with metal bumps, the position of the metal bumps is located in the central area that meets the SIM card pin specification. On the side of the flexible circuit board with metal bumps, there are flip-chip pads 19 such as Figure 9 As shown, the pads are respectively connected to the metal bumps of the SIM film card or the pins of the SIM film card through the lines of the flexible board, so as to realize the physical interface of the universal integrated circuit card (UICC) physically connected to the mobile phone terminal on one side. , and the other side has a physical interface that physically connects to a standard Universal Integrated Circuit Card (UICC).

[0046] The flexible circuit board assembly of the SIM film card is designed as Figure 8~9 As shown, a single splicing block unit flexible circuit board substrate contains multiple SIM film card flexible circuit boards. The entire substrate can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com