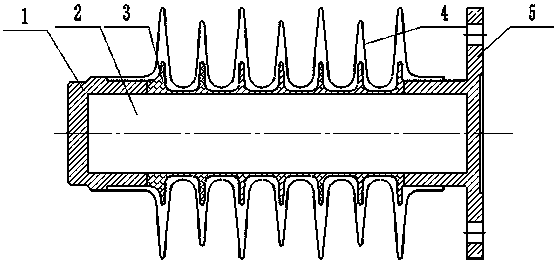

Wind-resistant composite insulator and preparation process thereof

A composite insulator and preparation process technology, applied in the field of power transmission and transformation, can solve problems such as fatigue fracture of silicone rubber materials, and achieve the effect of solving tearing and ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 1) According to the ratio of epoxy resin HW-12 and curing agent H-001 according to the mass ratio of 2:3.1, add them to the two tanks of the injection machine respectively;

[0026] 2) Heat the two tanks of the injection machine to 45-55°C, turn on the stirring and vacuum at the same time to preheat the material; the vacuum degree of the pretreatment process is ≤1.0 Pa, and the treatment time is 4 hours;

[0027] 3) Prepare the FRP mandrel and fittings, and crimp them. The crimped mandrels must meet the national standards and be checked one by one. Roughen the surface of the crimped mandrel with 200-320 mesh sandpaper, and wipe the surface with alcohol to ensure that the surface is free of oil, dust and other impurities.

[0028] 4) After the surface treatment of the mandrel is completed, put it into the oven and preheat it at 130±3℃ for 30min. Wrap 7-8 circles of raw material tape on both ends of the preheated mandrel (sealed at both ends), install it in the cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com