Continuous pass-through crushing station

A technology of crushing station and crushing box, which is applied in the direction of grain processing, etc., can solve the problems of long installation and commissioning period, high investment cost, poor equipment mobility, etc., and achieve the effect of reducing infrastructure cost, labor intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

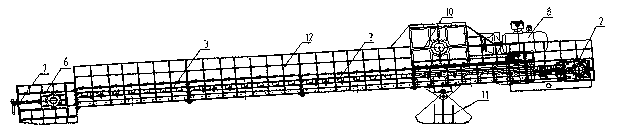

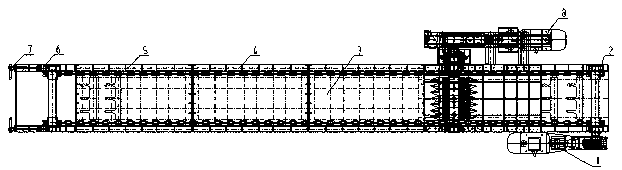

[0026] Such as figure 1 , figure 2 As shown, the continuous passing crushing station includes a conveying device and a crushing device. The conveying device is composed of a conveying drive 1, a conveying drive 2, a conveying box 3, a scraper 4, a drive shaft frame 5, a driven shaft frame 6, and a material baffle 9; the crushing device is mainly composed of a crushing drive 7, a crushing Box 8 and so on.

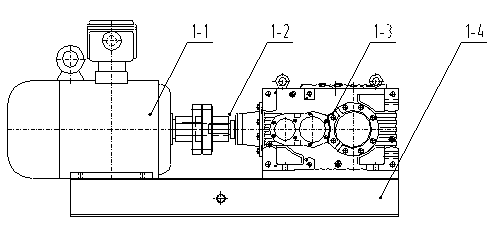

[0027] Three identical conveying boxes are connected by high-strength bolts to form an integral conveying box 3 with a certain length. The driven shaft frame 6 in the frame is connected to one end of the conveying box 3 through high-strength bolts, and the chain tightening device is fixed on the driven shaft. On the frame 6, the relative position of the driven shaft 2-4 can be changed by adjusting the chain tightening device, so as to achieve the purpose of tensioning the ring chain 2-2; Inlet. The conveying box body 3 is provided with a middle plate and a bottom plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com