Shale gas directional fracturing yield-increasing method

A directional fracturing and shale gas technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems that the distribution of shale gas cannot adapt to the transformation of shale gas reservoirs and the low permeability of reservoirs. , to achieve the effect of avoiding direction randomness, increasing penetration rate and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

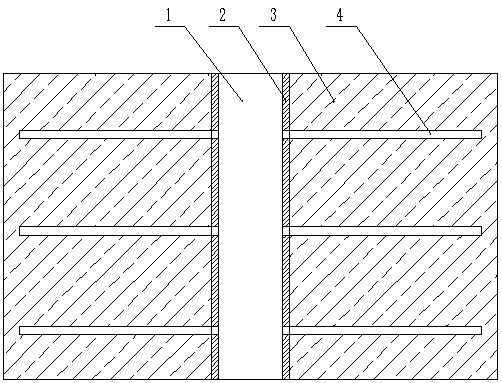

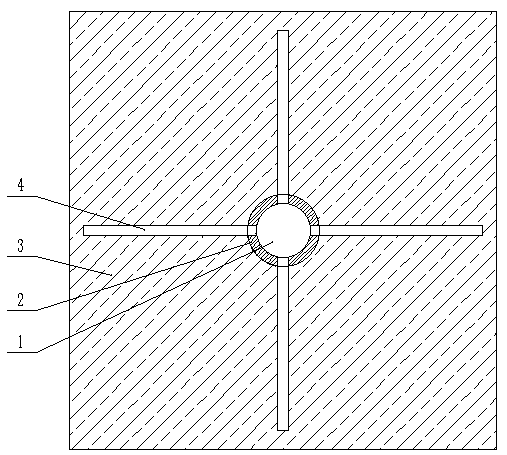

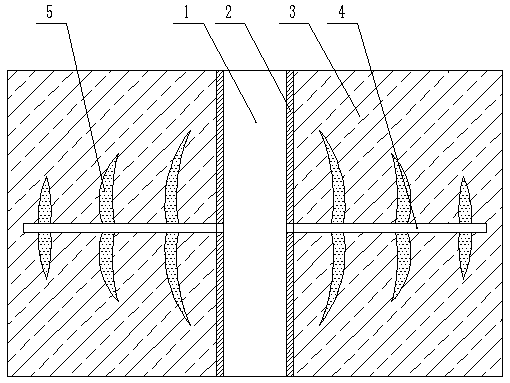

[0019] Such as Figure 1-3 As shown, this embodiment relates to a shale gas directional fracturing stimulation method, comprising the following steps:

[0020] a. Drill the vertical well 1 and cement the well with the casing 2; the well shall be drilled with conventional technology, and the drilling depth should not exceed 3,500 meters. After the depth is greater than 3,500 meters, it is no longer suitable for mining due to geothermal problems method. When cementing with casing 2, it is preferable to use 5-inch or 5.5-inch casing for cementing, and the pressure-resistant grade parameter of casing 2 should not be less than 15,000 psi, and a high-pressure casing should be used.

[0021] b. Drill a number of thin radial wells 4 in different radial directions in different flat layers; according to the formation detection results, use the radial well drilling device to drill holes on the casing 2 in the preset direction, and then drill into the shale layer 3 A certain depth is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com