Coal bed methane exploring method of spraying gas-water mixed liquid to drill well and forming quincunx radial horizontal well

A technology of jet drilling and mixed fluid, which is applied in liquid/gas jet drilling, drilling equipment and methods, and mining fluids, etc. It can solve problems such as invalid construction control, easily polluted coal seams, and complex working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

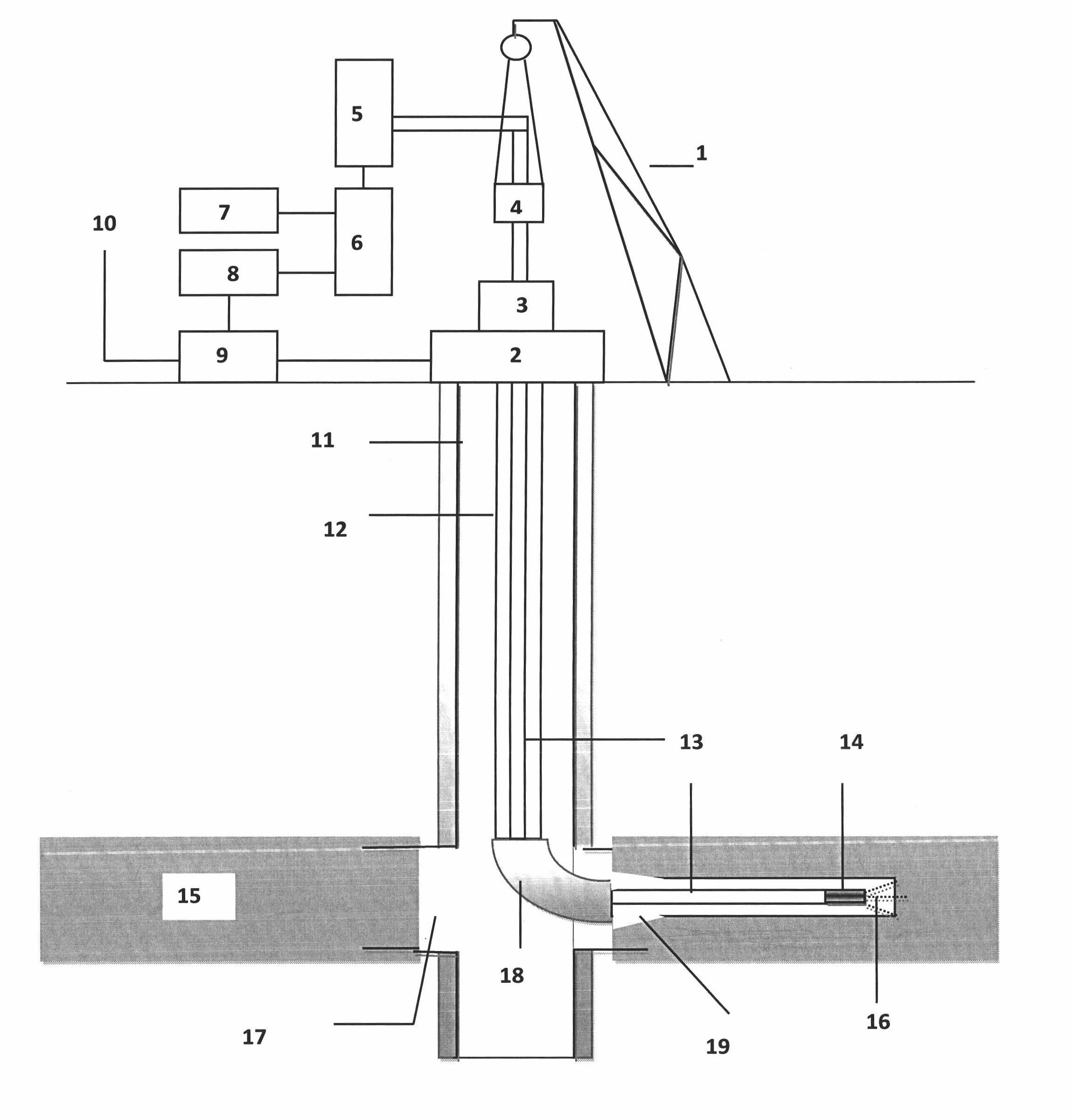

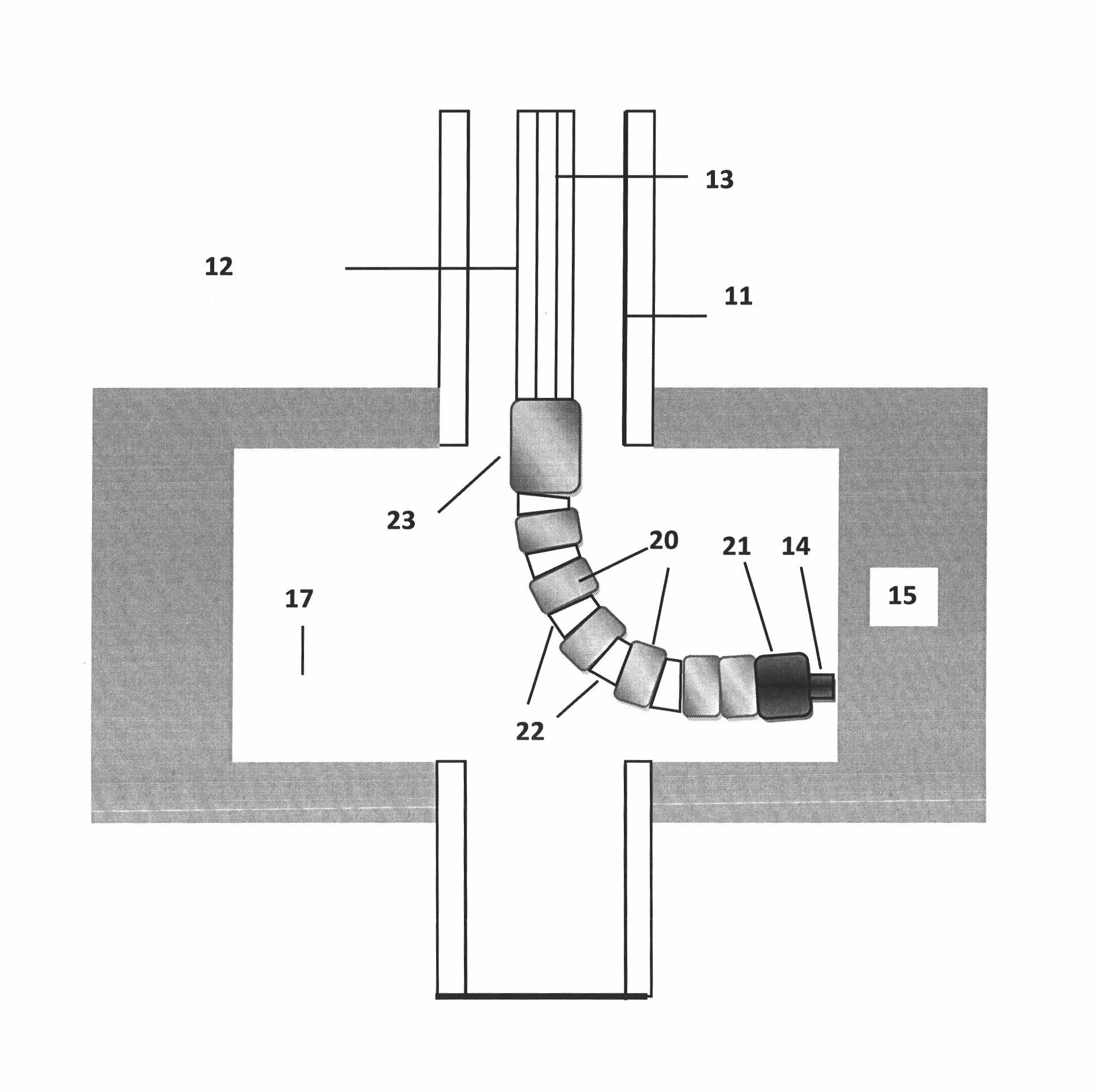

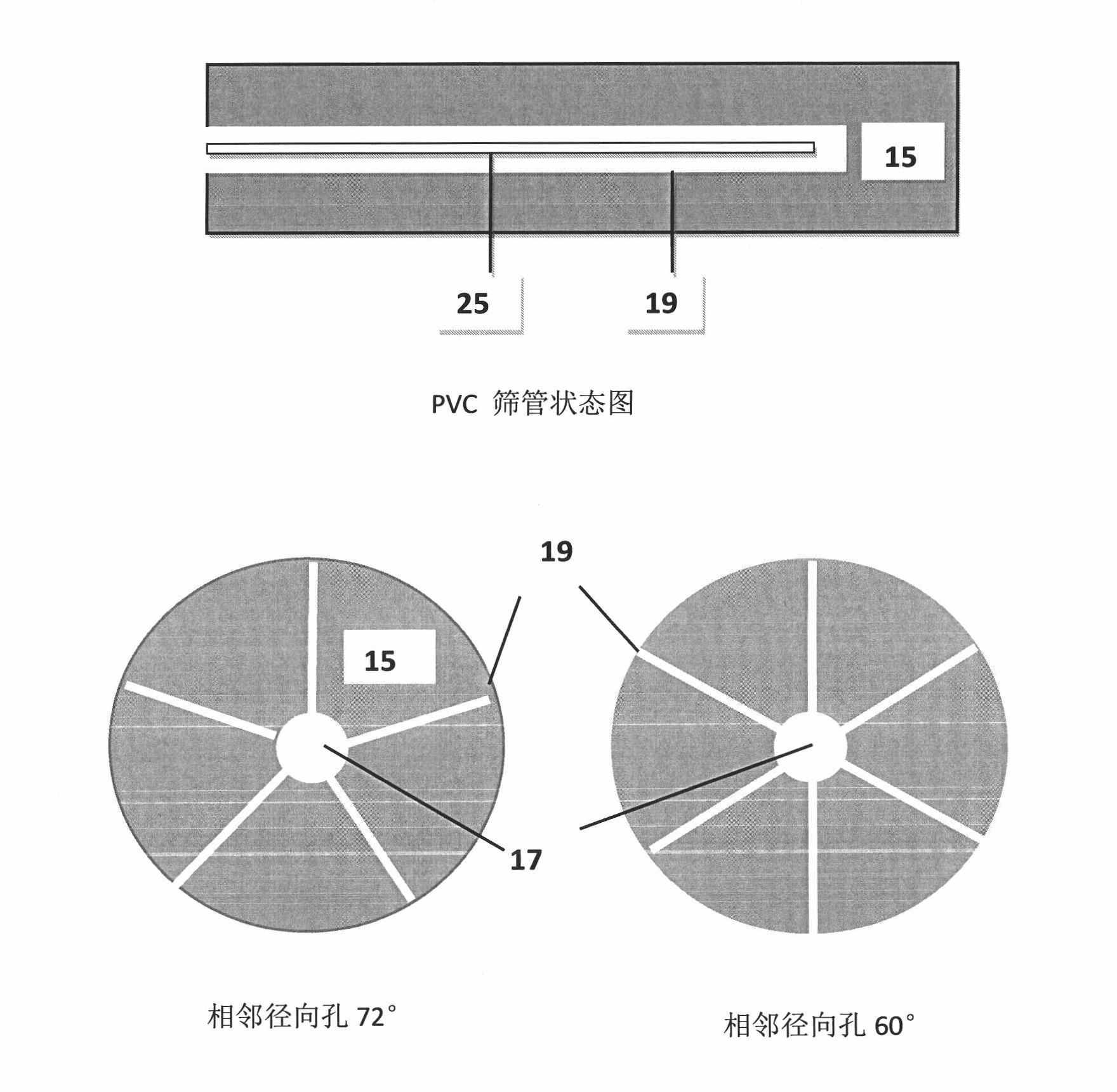

[0017] Such as figure 1 As shown, the two-stage reaming of the coal seam well section is to use a mechanical or hydraulic reamer to expand a smaller-diameter borehole in the coal seam well section, and then run a larger-diameter reamer to perform secondary reaming of the coal seam. hole, so that the borehole diameter of the coal seam section is reamed to a cave 17 with a diameter of about 1000mm. Its function is to eliminate the pollution of the coal seam during drilling and cementing, and to eliminate the obstruction of the casing wall to the stagnation of the mixed fluid during the jet drilling process to form a certain degree of "overpressure" in the radial hole, reducing the The pulverized coal produced during jet drilling invades and blocks the coal seam around the radial hole, and the third is to provide a radially oriented tool 18 activity space, so that radial guidance can be realized.

[0018] Such as figure 1 As shown, the high-pressure gas-water mixture jet drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com