Three-dimensional interconnected hierarchical-structured zeolite molecular sieve material and preparation method thereof

A zeolite molecular sieve and pore structure technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of complex operation, inability to adjust the pore diameter of the pore, reaction conditions, and equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

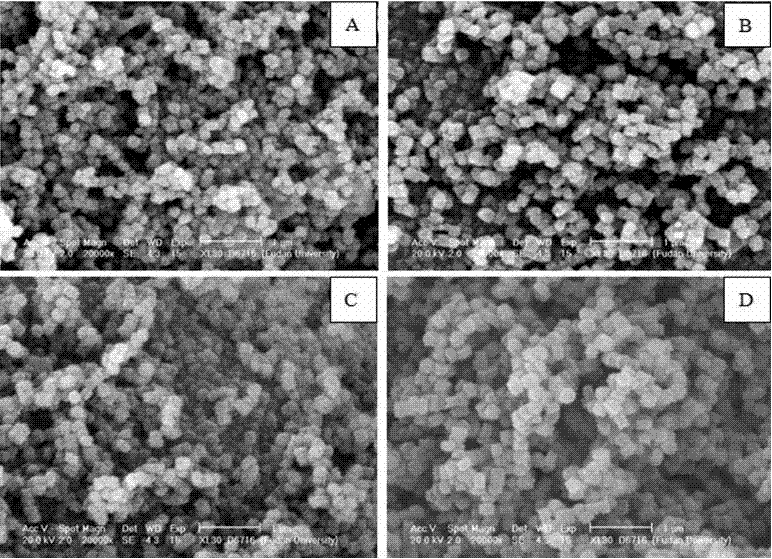

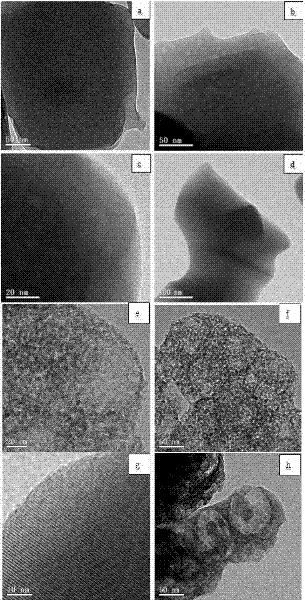

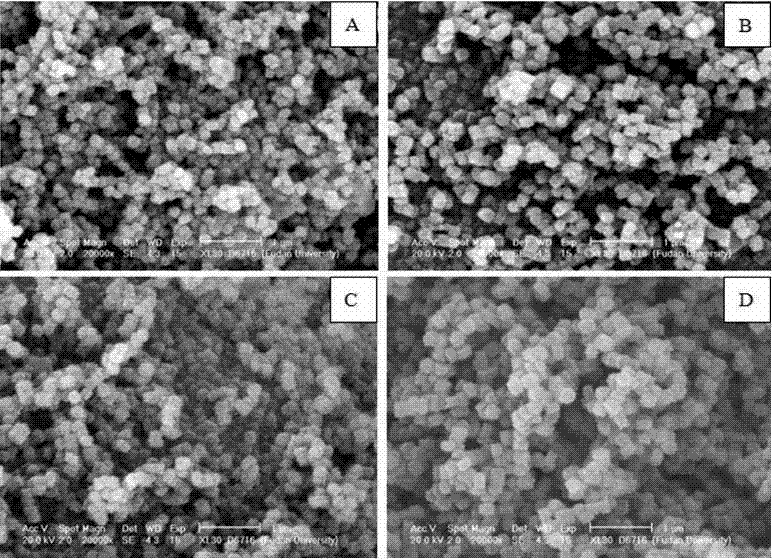

Image

Examples

Embodiment 1

[0027] (1) Prepare PDDA and DBS into a 1wt% aqueous solution, and then prepare a solution according to the volume ratio of PDDA / DBS solution of 10:11, mix it evenly, and let it stand as a templating agent for later use.

[0028] (2) Mix 4ml of template agent with 4.0g of 50wt% TPAOH and a small amount of distilled water under vigorous stirring. After stirring for half an hour, slowly add 5g of TEOS and 0.1g of AIP (which can be dissolved in a small amount of distilled water first) into the reaction system. Then add about 10ml of distilled water.

[0029] (3) After further stirring at room temperature for 24 h, the reactants were transferred to the substrate of a hydrothermal kettle and crystallized at 150-200 °C for 2-3 days.

[0030] (4) After the product is centrifuged and washed with distilled water, it is dried in a vacuum oven at a constant temperature of 45°C, and then calcined at 550°C for 3~5h to remove the template.

[0031] (5) The product is a white solid, which...

Embodiment 2

[0033] (1) Prepare PDDA and DBS into a 1wt% aqueous solution, and then prepare a solution according to the volume ratio of PDDA / DBS solution of 10:11, mix it evenly, and let it stand as a templating agent for later use.

[0034] (2) Mix 10ml of template agent with 3.5g of 50wt% TEAOH and a small amount of distilled water under vigorous stirring. After stirring for half an hour, slowly add 4~6g of sodium silicate and 0.1g of aluminum sulfate (dissolved in a small amount of distilled water first) reaction system and add a small amount of NaOH. Add approximately 4 ml of distilled water.

[0035] (3) After further stirring at room temperature for 24 h, the reactants were transferred to the substrate of a hydrothermal kettle and crystallized at 150-200 °C for 2-3 days.

[0036] (4) After the product is centrifuged and washed with distilled water, it is dried in a vacuum oven at a constant temperature of 45°C, and then calcined at 550°C for 3~5h to remove the template.

[0037] ...

Embodiment 3

[0039] (1) Combine PDDA and AOS 16 Prepared into 1wt% aqueous solution, and then according to PDDA / AOS 16 The volume ratio of the solution is 10:7 to make a solution, mix it evenly and let it stand as a template for later use.

[0040] (2) Mix 10ml template agent with 4.0g 50wt% TPAOH and a small amount of distilled water under vigorous stirring. After stirring for half an hour, slowly add 5g TEOS and 0.2 g AIP (dissolved in a small amount of distilled water) into the reaction system slowly. Then add about 5ml of distilled water.

[0041] (3) After further stirring at room temperature for 24 h, the reactants were transferred to the substrate of a hydrothermal kettle and crystallized at 150-200 °C for 2-3 days.

[0042] (4) After the product is centrifuged and washed with distilled water, it is dried in a vacuum oven at a constant temperature of 45°C, and then calcined at 550°C for 3~5h to remove the template.

[0043] (5) The product is a white solid, which turns into a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com