Catalytic module capable of removing formaldehyde at room temperature and preparation method thereof

A technology for eliminating formaldehyde and room temperature, applied in the field of air purification, can solve the problems of unfavorable reaction molecular adsorption product molecular desorption, limit the wide application of catalyst, reduce catalyst efficiency and other problems, achieve excellent low temperature activity and removal efficiency, low noble metal loading, The effect of improving catalytic activity and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

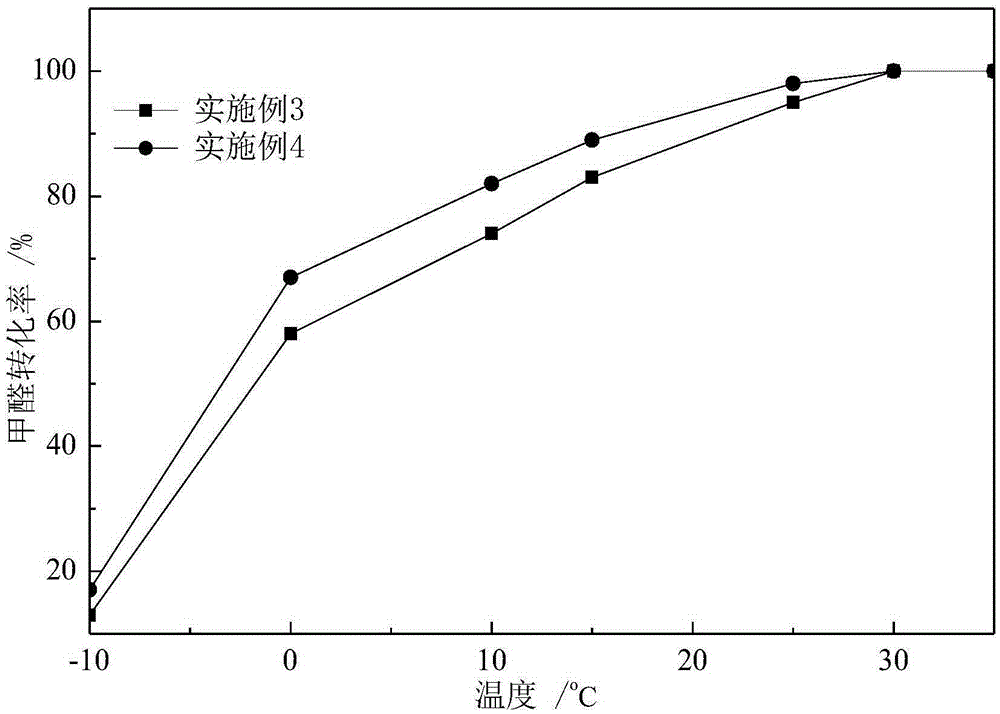

Examples

preparation example Construction

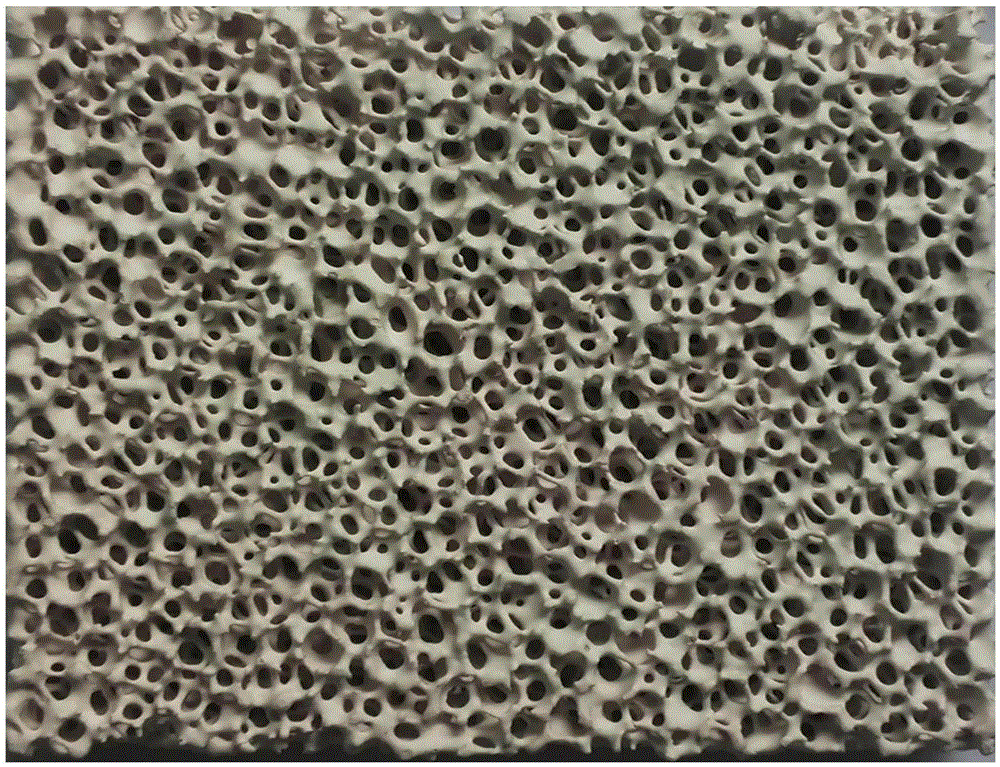

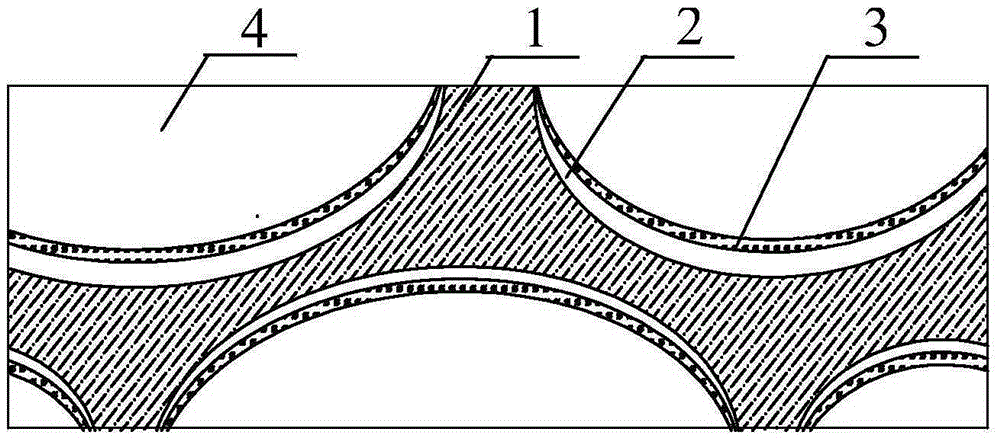

[0057] A method for preparing a catalytic module that eliminates formaldehyde at room temperature, the preparation of the above-mentioned catalytic module includes the following steps: coating the coating 2 on the surface of the foamed ceramic structure by a vacuum coating method, and then using the dipping method or precipitation method on the coating 2 The step of carrying the catalyst layer 3 on the surface so as to obtain the catalytic module, the specific operation process includes the following steps:

[0058](1) Mix 10-40 parts by weight of coating precursor powder, 0.1-20 parts by weight of binder, 0.01-5 parts by weight of film-forming aid and deionized water, and the deionized water and coating precursor The mass ratio of the powder is 9:1~6:4; place the uniformly mixed slurry on a disperser, and disperse it at 300~550r / min for 20~60min; then use nitric acid or hydrochloric acid solution with a mass concentration of 5~20% to dissolve Adjust the pH of the slurry to pH...

Embodiment 1

[0072] Embodiment 1 Foam ceramic structure surface coating coating 2:

Embodiment 1-1

[0074] 50gTiO 2 (Type A), 1.5gHPMC-6000, 0.25g fatty alcohol polyoxyethylene ether (R=C16~18, n=20) and 250mLH 2 O Mix evenly, put it on a disperser and disperse at 350r / min for 30min, adjust the pH of the slurry to 3~4 with a 10% nitric acid solution, and continue to disperse for 15min; transfer the slurry to a sand mill for 1.5h Then transfer it to the storage tank of the vacuum coating machine, and then place the silicon carbide foam ceramic structure with a size of 100×100×20mm in the sample chamber for vacuum coating for 10 minutes, and use compressed air to blow out the excess slurry in the channel 4.

[0075] Put the slurry-coated foam ceramics in a curing box at 25°C and a relative humidity of 70% for 6 hours, dry at 80°C for 6 hours, and bake at 400°C in air flow for 4.0 hours to obtain carrier 1-1. 2 The coating amount is 57.8g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com