Semiconductor porcelain plate sand blasting machine capable of performing timing rotating sand blasting

A sandblasting machine and semiconductor technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of high labor intensity, poor sandblasting effect, low work efficiency, etc., and achieve strong practicability, simple structure, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

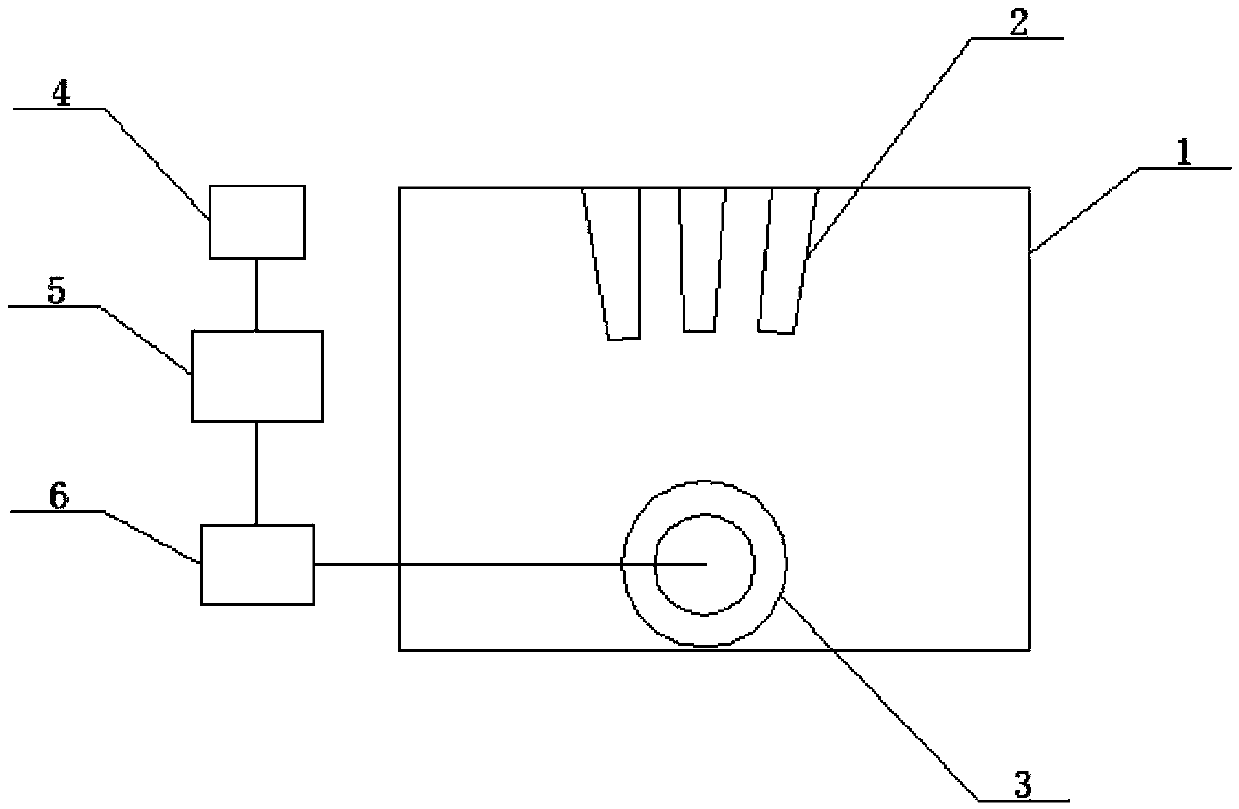

[0009] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a sandblasting machine body 1, a spray gun 2, and a turntable 3, and several spray guns 2 are arranged on the inner top of the sandblasting machine body 1, and several spray guns 2 are directed in the same direction, and the turntable 3 is set In the direction of several spray guns 2 in the sandblasting machine body 1, it also includes a timer 4, a controller 5, and a driver 6. The turntable 3 is connected to the driver 6 arranged outside the sandblasting machine body 1, and the driver 6 is connected to the controller 5 connection, the timer 4 is connected with the controller 5.

[0010] In this specific embodiment, when sandblasting the semiconductor porcelain plate, first estimate the required sandblasting time for the semiconductor porcelain plate, place the semiconductor porcelain plate on the turntable 3, then set the sandblasting time by the timer 4, and control The device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com