Manganese oxide reduction system of internal heating type rotary kiln

An internal heating rotary kiln and manganese oxide technology, applied in the field of internal heating rotary kiln reduction manganese oxide system, can solve the problems such as the influence and negative effects of the electrolysis section are difficult to solve, the process flow of the post-treatment section is complicated, and the efficiency is low and cannot be carried out. Achieve the effects of reduced energy consumption, high production capacity, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

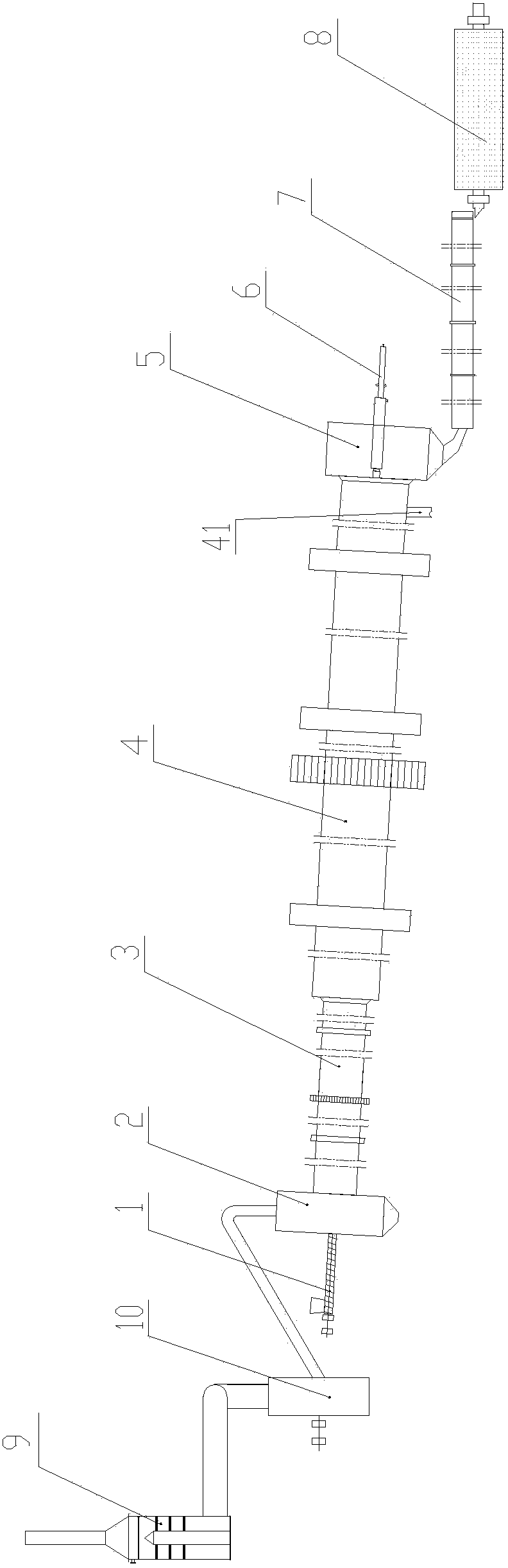

[0038] Such as figure 1 As shown, the internal heating rotary kiln reduction manganese oxide system provided by the present invention includes a screw feeder 1, a kiln head stove 2, a preheating drying kiln 3, an internal heating rotary kiln 4, and a kiln tail Stove 5, powder spray burner 6, water cooling conveyor 7, ball mill 8. The desulfurization and dust removal tower 9 is connected to the feed end of the preheating drying kiln 3 through the exhaust fan 10 and pipelines. The installation height of the screw feeder 1 is higher than that of the ball mill 8 , and the installation height of the desulfurization and dust removal tower 9 is higher than that of the screw feeder 1 . The preheating drying kiln 3 and the internal heating type rotary kiln 4 are connected end to end to form a whole when installed, and a sliding sealing device is adopted in the middle.

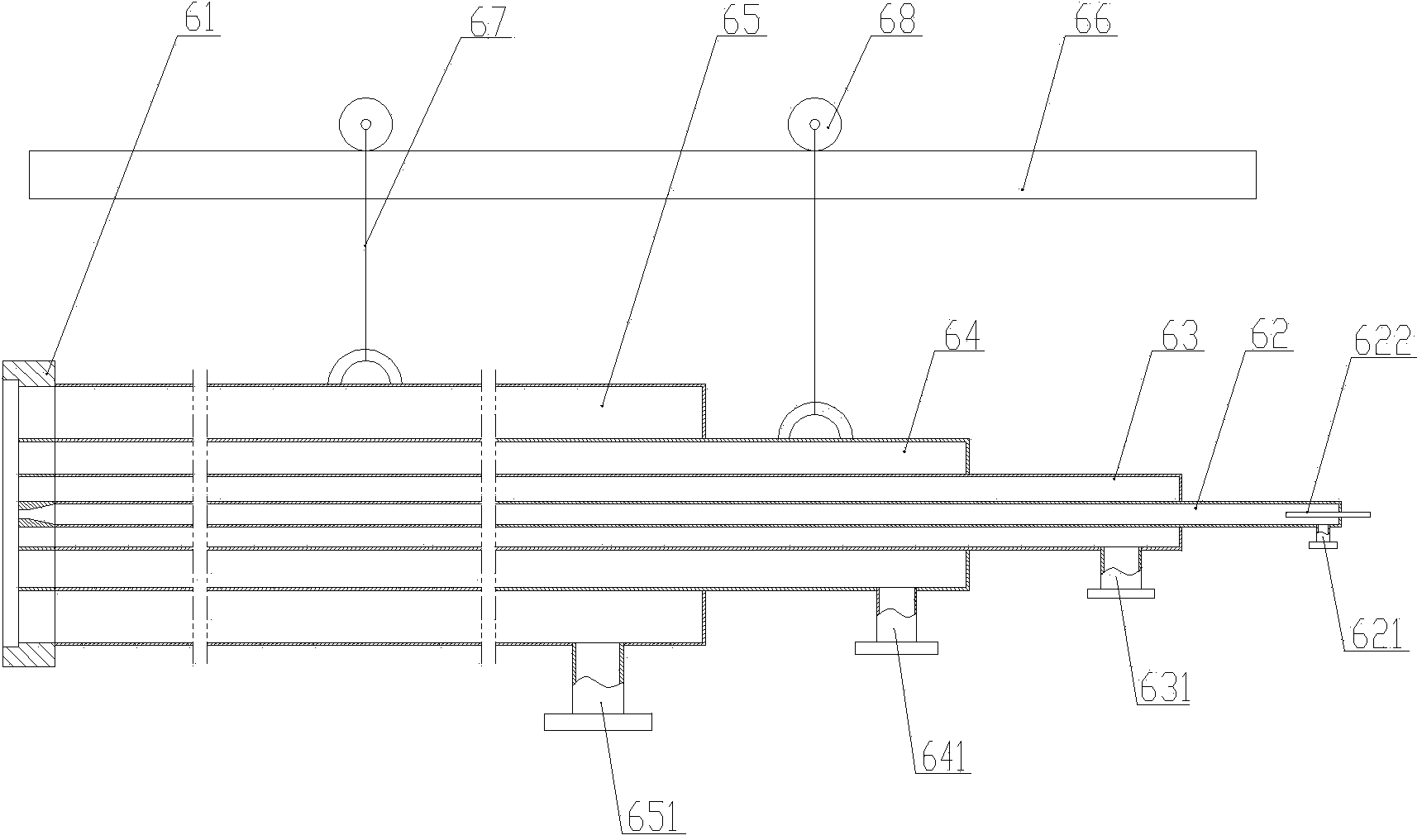

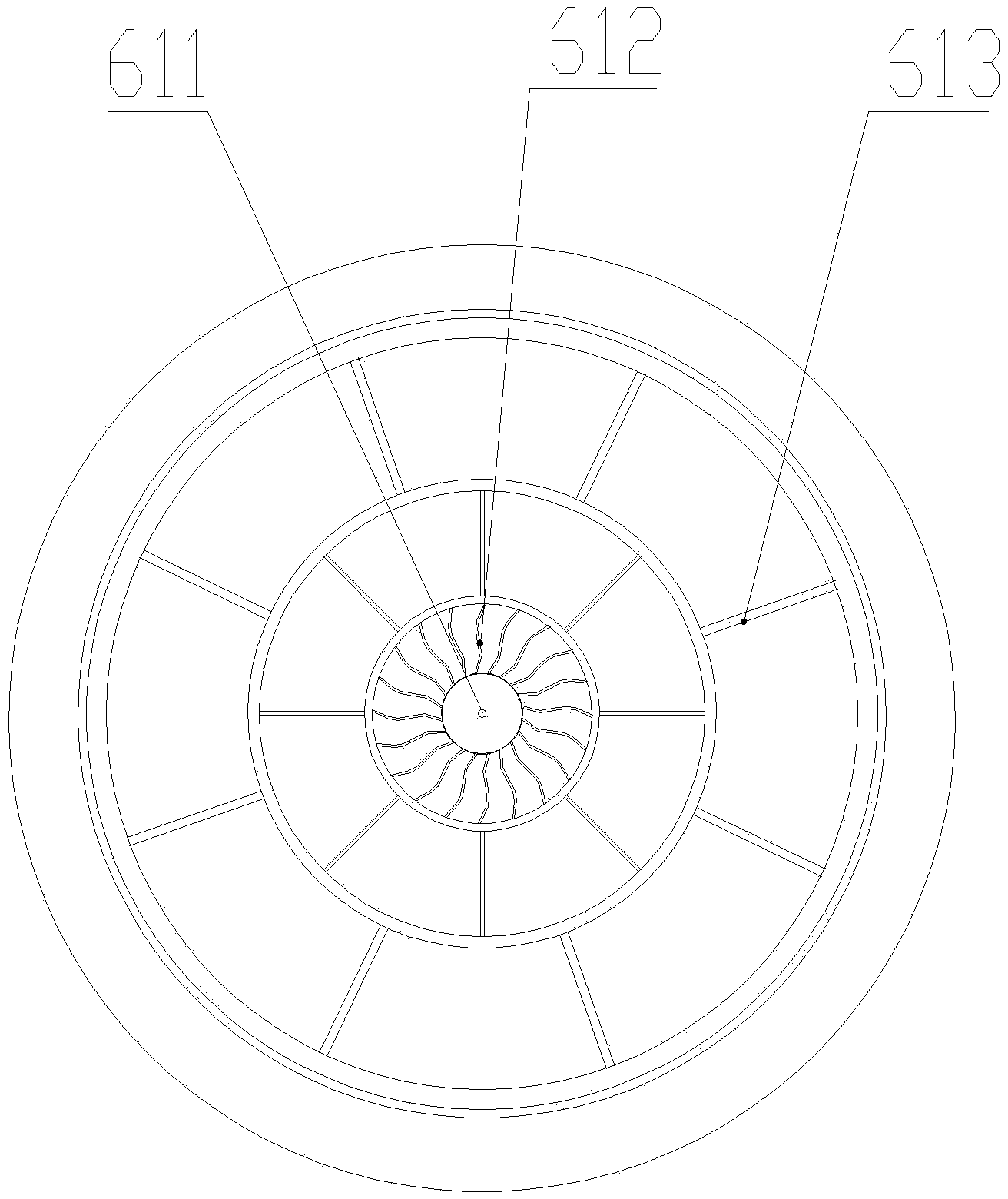

[0039] Such as figure 2 , image 3 As shown, the powder spraying burner 6 is a multi-channel burner, including a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com