Reaction device for anode or cathode material of lithium battery

A negative electrode material and reaction device technology, which is applied in the field of lithium battery positive electrode or negative electrode material reaction device, can solve the problems such as the process cannot be continuously produced, and achieve the effect of adapting to large-scale industrial production, precise production, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

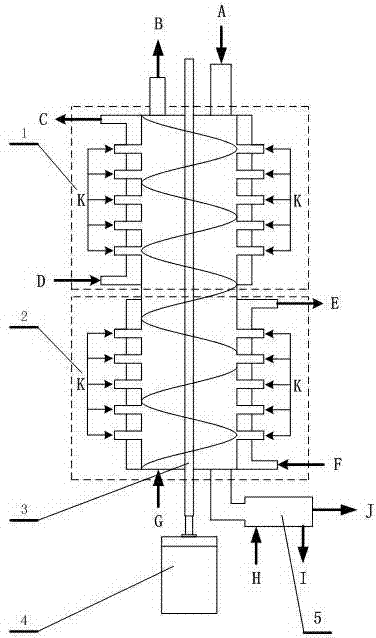

[0017] The mixture of lithium carbonate and manganese dioxide with a particle size of 0.1-100 μm is added to the preheating section 1 through the material inlet A, and high-temperature flue gas is introduced into the jacket of the preheating section 1 to maintain 300-500°C in the preheating section 1, After the mixture of lithium carbonate and manganese dioxide is preheated for several hours, it is directly pushed into the reaction section 2 by the screw feeding device. The high-temperature flue gas is introduced into the jacket of the reaction section 2, so that the reaction section 2 is maintained at 500-900 ° C. At this temperature, the mixture of lithium carbonate and manganese dioxide reacts for several hours to generate lithium manganate, and the generated manganese Lithium acid then enters cooling device 6. In the cooling device 6, the generated lithium manganate is cooled by surface water cooling. Cooling water enters the cooling device 6 from the water inlet H of the...

example 2

[0019] The mixture of lithium carbonate and titanium oxide with a particle size of 0.1-100 μm is added to the preheating section 1 from the material inlet A, and high-temperature flue gas is introduced into the jacket of the preheating section 1 to maintain 300-500°C in the preheating section 1, After the mixture of lithium carbonate and titanium oxide is preheated for several hours, it is directly pushed into the reaction section 2 by the screw feeding device. The high-temperature flue gas is introduced into the jacket of the reaction section 2 to maintain the temperature in the reaction section 2 at 500-900°C. At this temperature, the mixture of lithium carbonate and titanium oxide will react for several hours to form lithium titanate, and the produced titanium Lithium acid then enters cooling device 6. The generated lithium titanate is cooled by surface water cooling in the cooling device 6 . Cooling water enters the cooling device 6 from the water inlet H of the cooling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com