Patents

Literature

38results about How to "Avoid process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

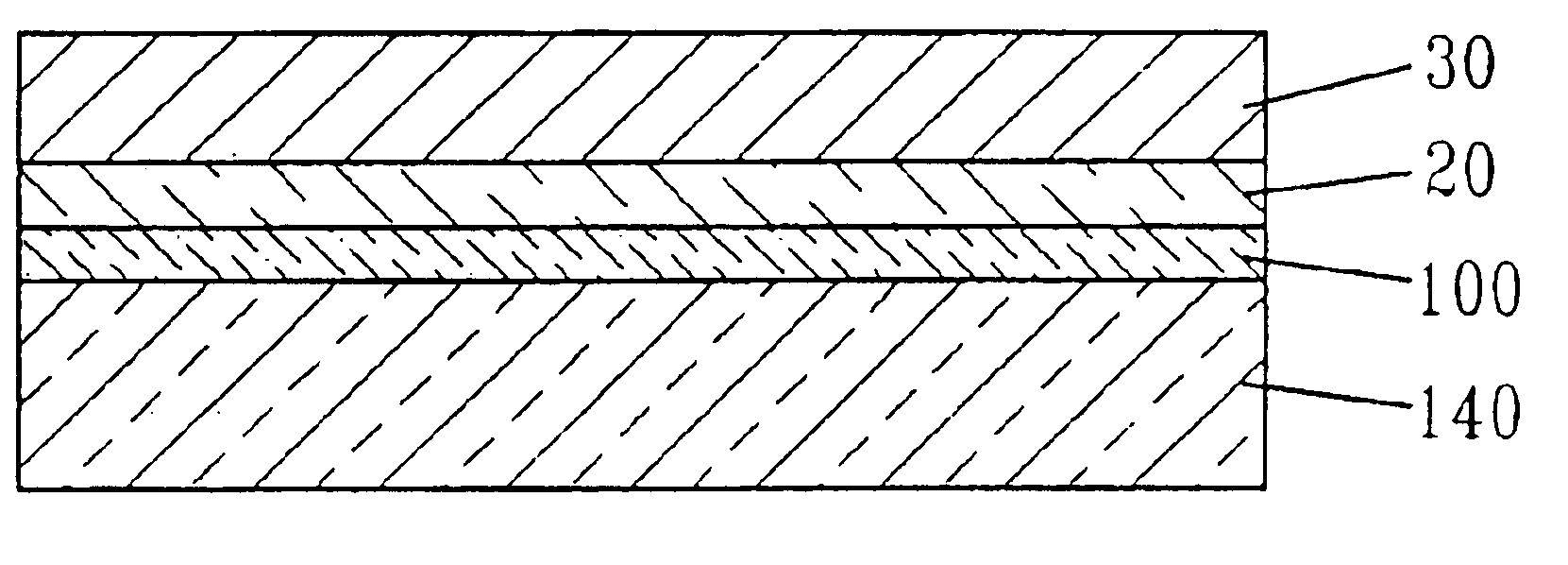

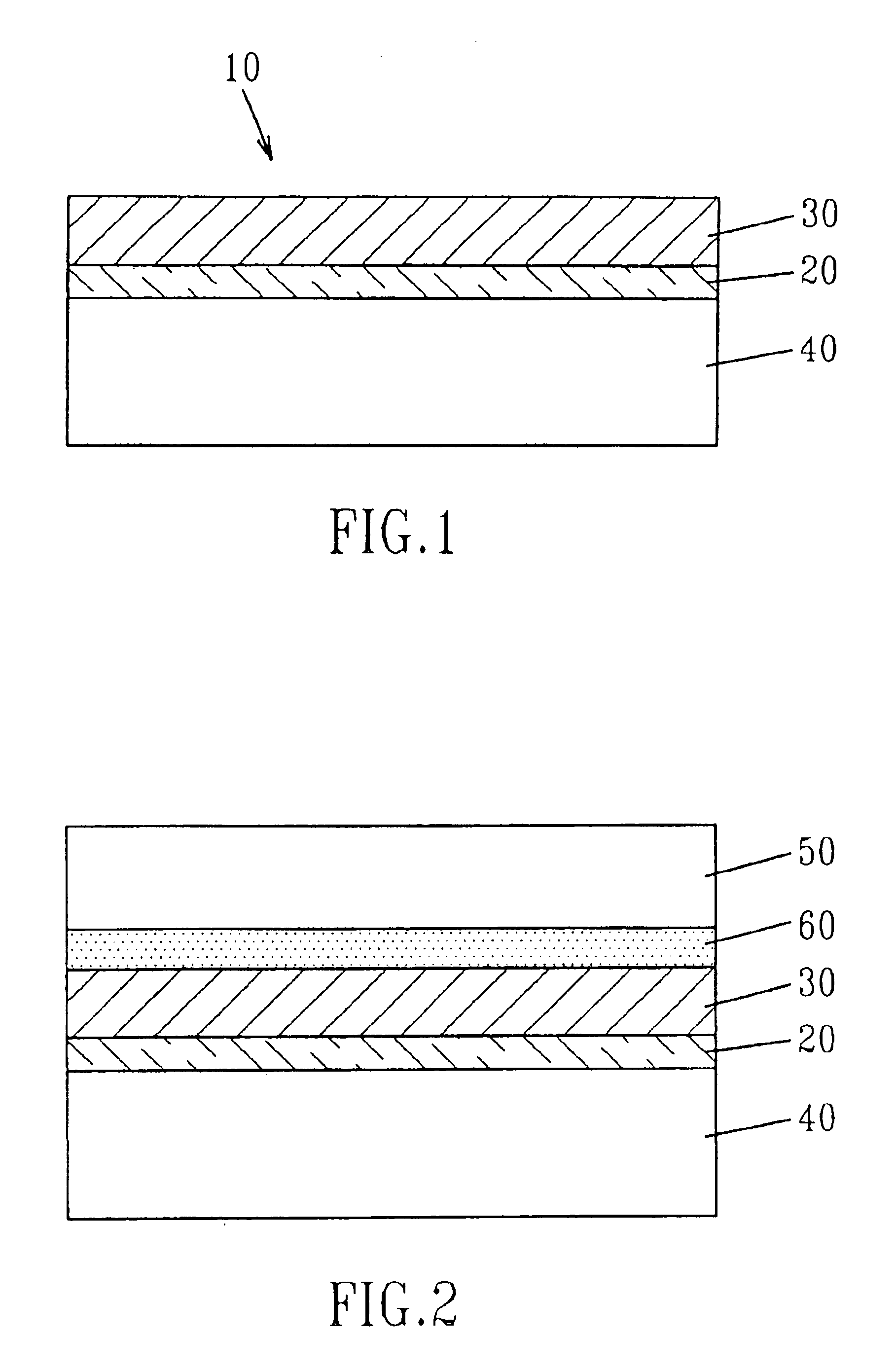

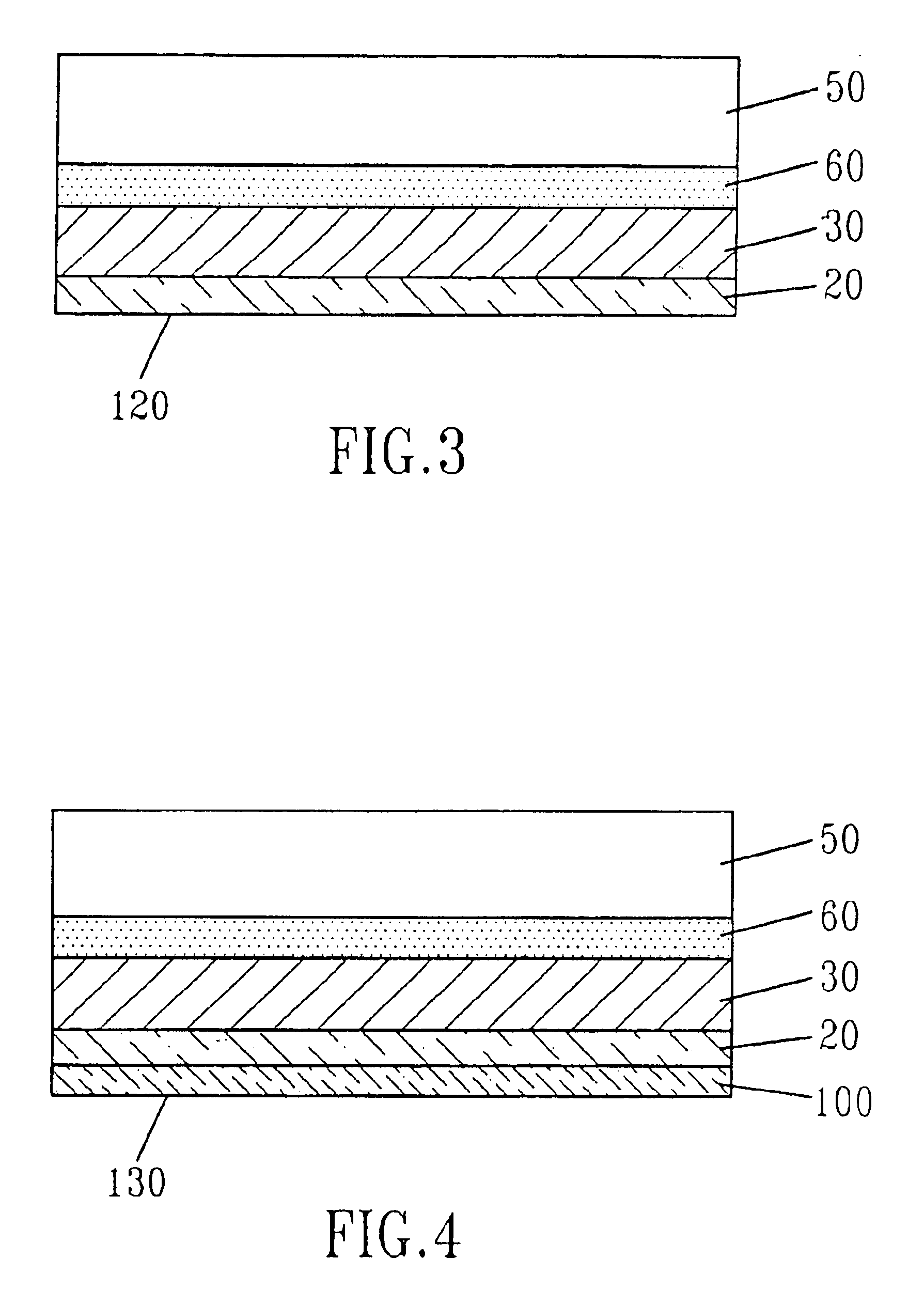

Method of fabricating silicon devices on sapphire with wafer bonding at low temperature

InactiveUS6911375B2Avoid process stepsCost effectiveSolid-state devicesSemiconductor/solid-state device manufacturingWaferingWafer bonding

Described is a method for making silicon on sapphire structures, and devices therefrom. The inventive method of forming integrated circuits on a sapphire substrate comprises the steps of providing a device layer on an oxide layer of a temporary substrate; bonding the device layer to a handling substrate; removing the temporary substrate to provide a structure containing the device layer between the oxide layer and the handling substrate; bonding a sapphire substrate to the oxide layer; removing the handling substrate from the structure; and annealing the final structure to provide a substrate comprising the oxide layer between the device layer and the sapphire substrate. The sapphire substrate may comprise bulk sapphire or may be a conventional substrate material with an uppermost sapphire layer.

Owner:IBM CORP

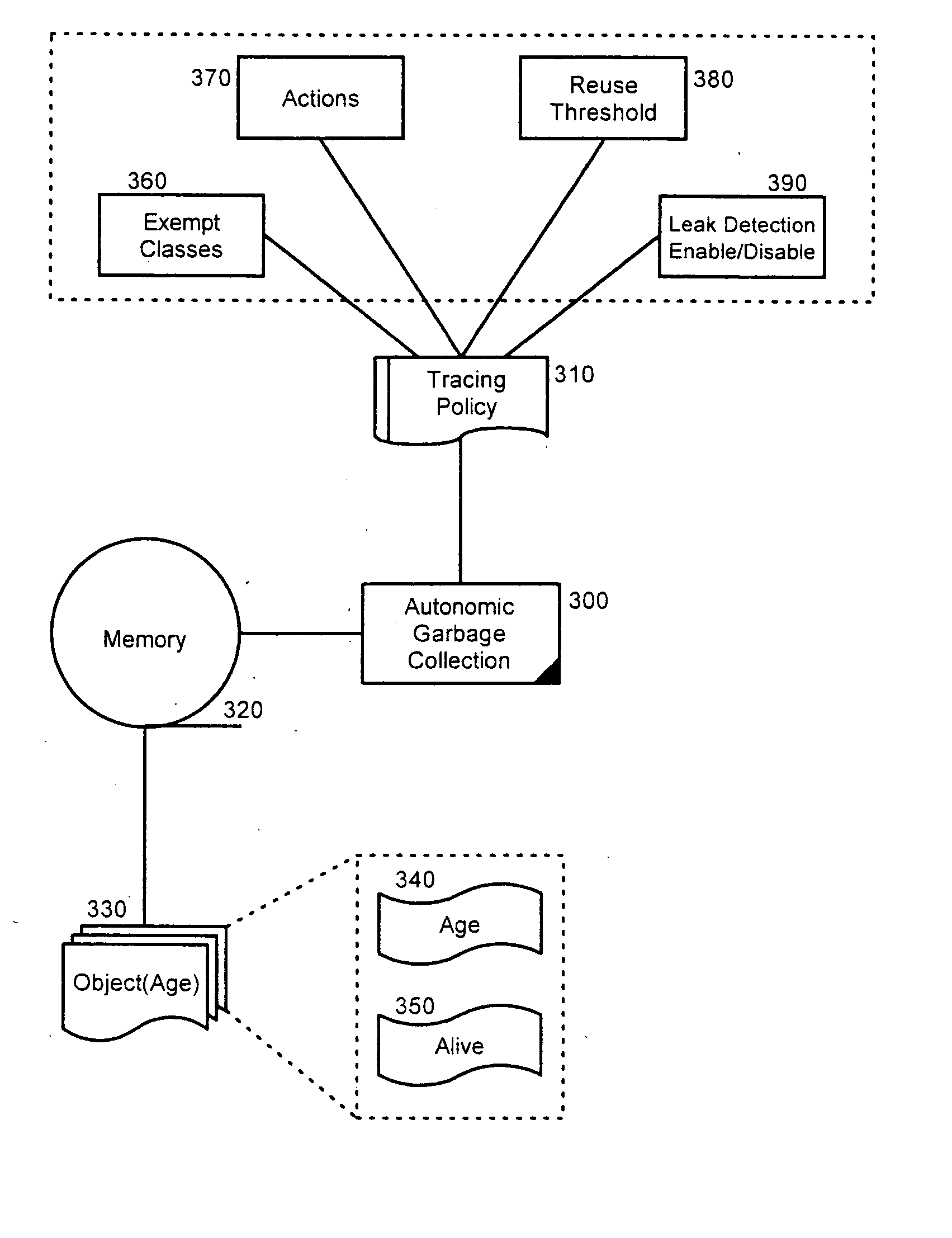

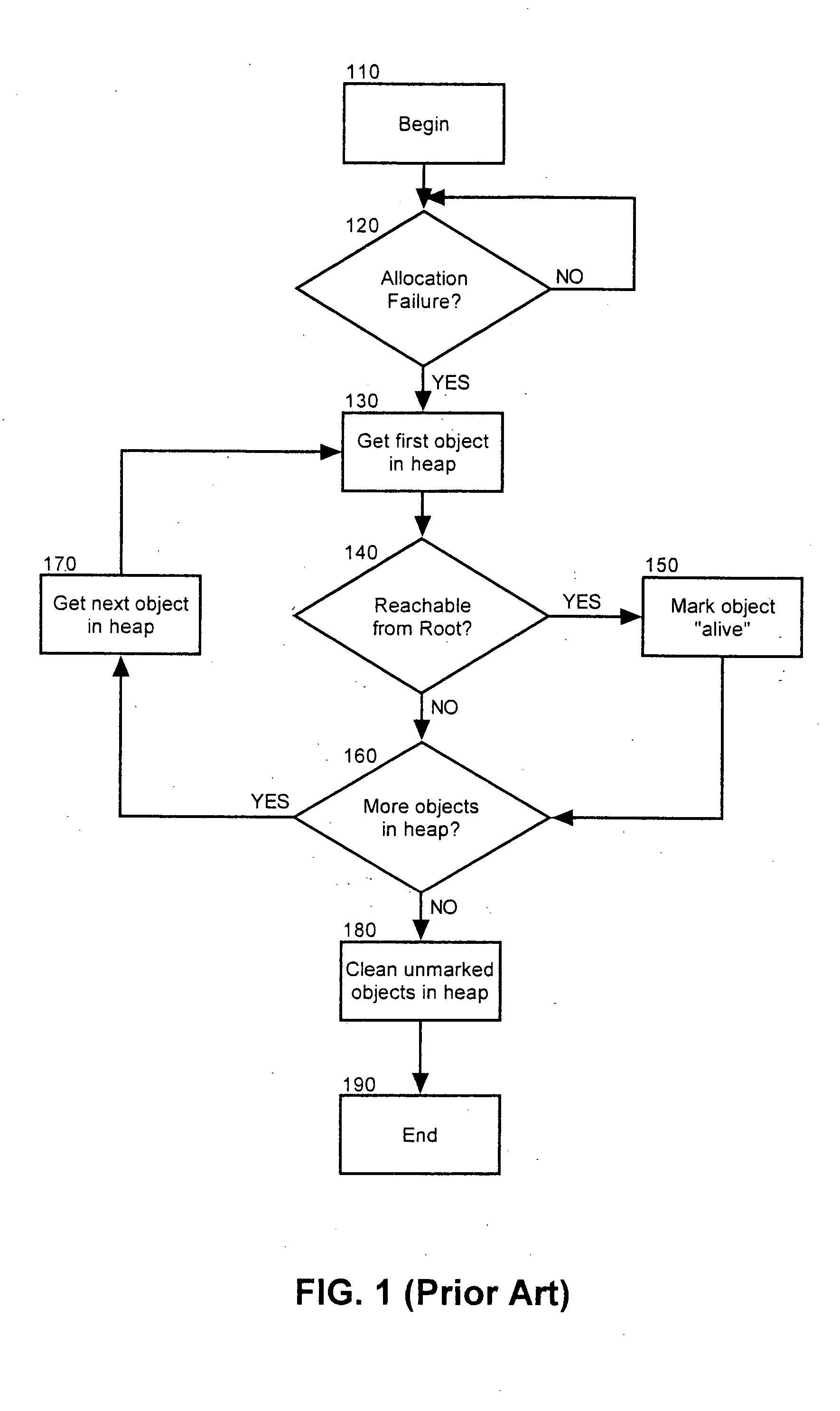

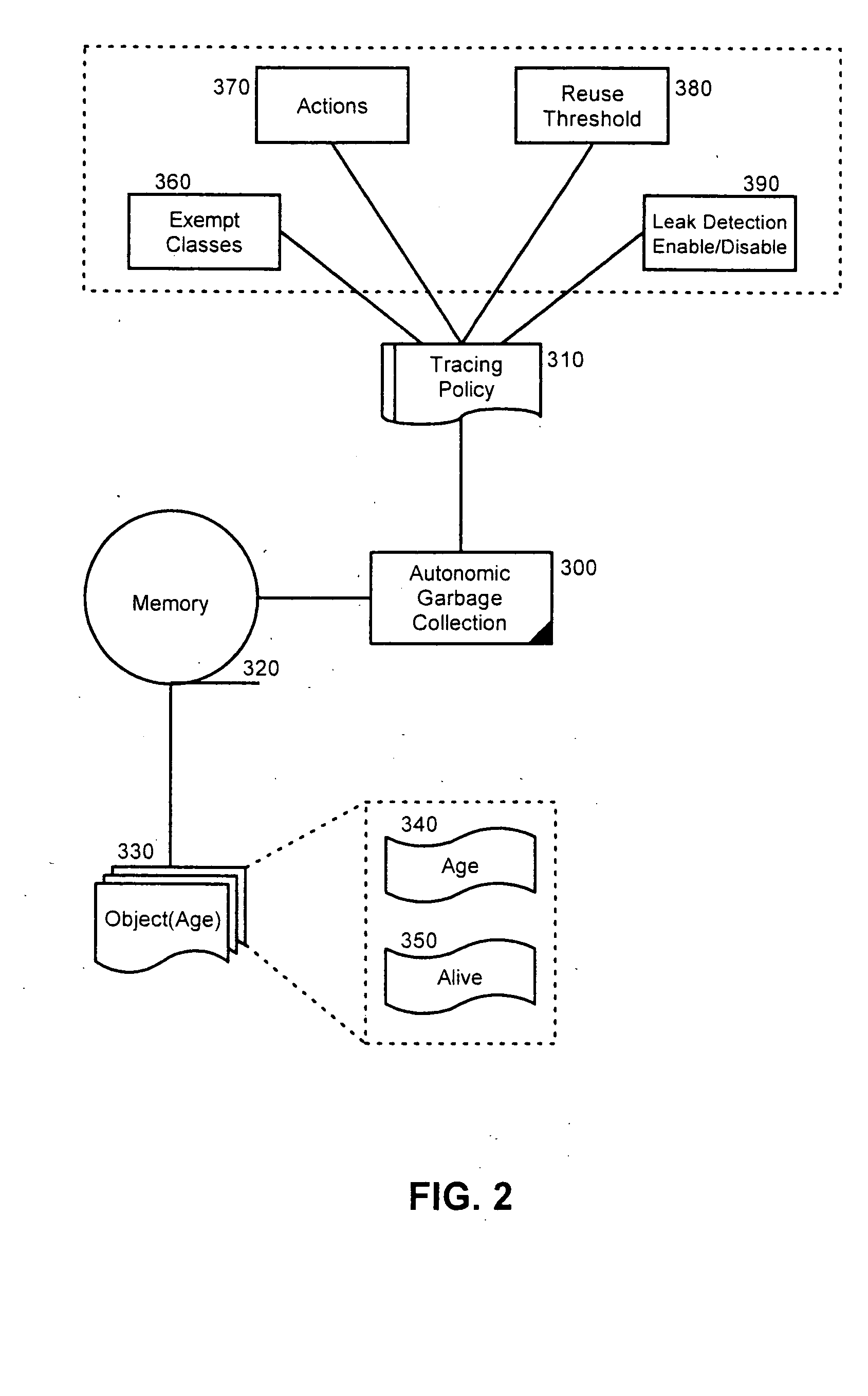

Autonomic memory leak detection and remediation

InactiveUS20050081190A1Process step be avoidAvoid process stepsMemory adressing/allocation/relocationHardware monitoringMemory leak detectionAge values

A method, system and apparatus for detecting and remediating a memory leak. In the method of the invention, an aging value can be established for an object instance created in memory and resetting the aging value when the object instance is referenced by an executing process. By comparison, the aging value can be incremented during a garbage collection pass when the object instance had not been referenced by an executing process since a previous garbage collection pass. Importantly, when the aging value exceeds a threshold value, the object instance can be processed as a loiterer. The processing step itself can include clearing at least one cache in memory, and reporting said object instance as a loiterer in a log file. Yet, the processing step can be avoided where the object instance belongs to a specified exempt class.

Owner:IBM CORP

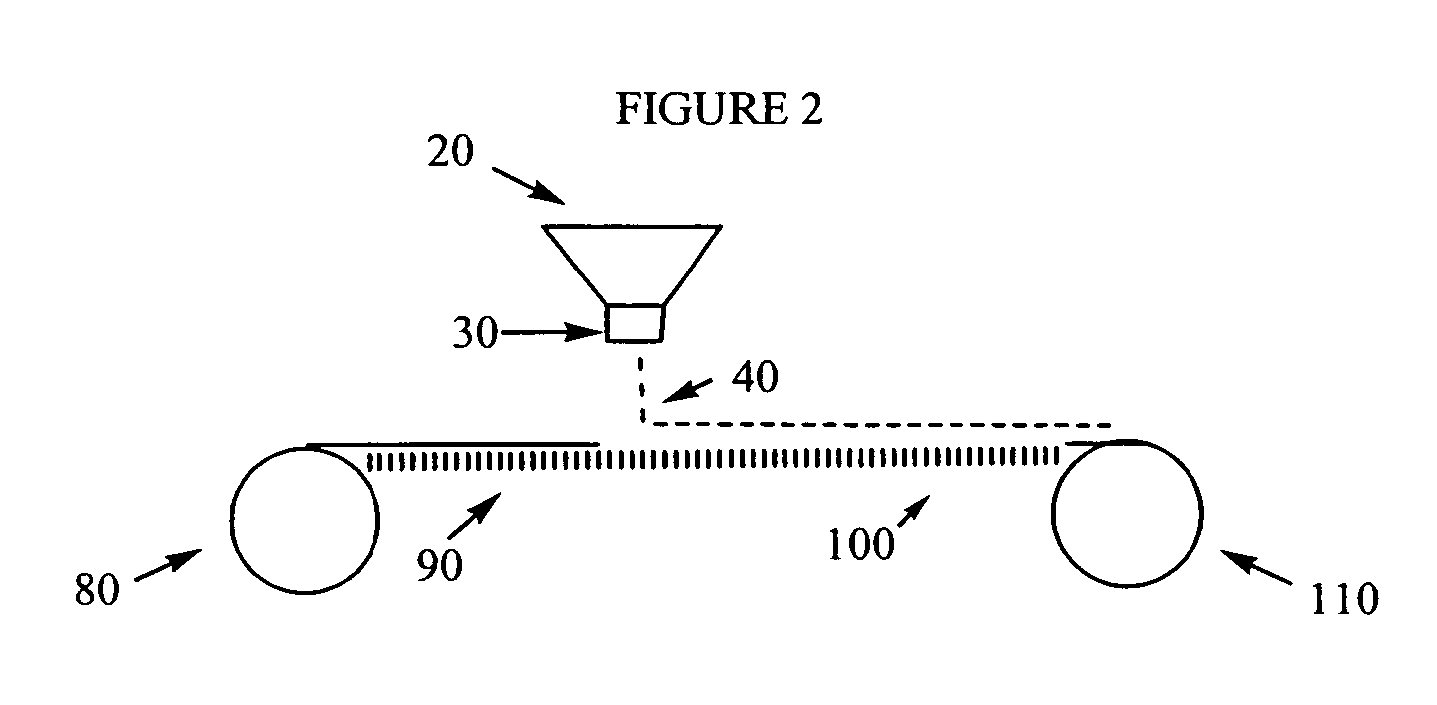

Composite materials

InactiveUS20070082172A1Acceptable sound-absorbent propertyReduce usageSynthetic resin layered productsLaminationFiberWater based

A noise reducing composite material for use in automotive applications, and methods for preparing the material, are disclosed. The composite includes a carpet layer and a noise reducing layer. The carpet layer can be a tufted carpet layer that includes a primary backing in which to position tufts of yarn, and a latex layer to lock in the tufts of yarn, or a nonwoven carpet layer with a coating of latex to lock in the fibers. The noise reducing layer is adhered to the carpet layer. The latex layer includes, as an additive, an adhesive of sufficient type and quantity to adhere the noise reducing layer to the carpet layer. Latex dispersions including such additives, which can be used to form the latex layer in the composite material, are also disclosed. Examples of noise reducing layers include heavily filled EVA, shoddy, and foam layers. For adhering shoddy and / or foam layers, the additive in the latex layer is a polyolefin, such as polyethylene. For adhering filled EVA layers, the additive in the latex layer is a water-based adhesive such as an ethylene acrylic acid ammoniated dispersion. The composite carpet materials described herein represent an improvement over the existing carpet materials, in that they can be manufactured using wet steps, without the need for organic solvents, and reduce the number of process steps by eliminating the need for an extruded polyethylene layer.

Owner:MALLARD CREEK POLYMERS

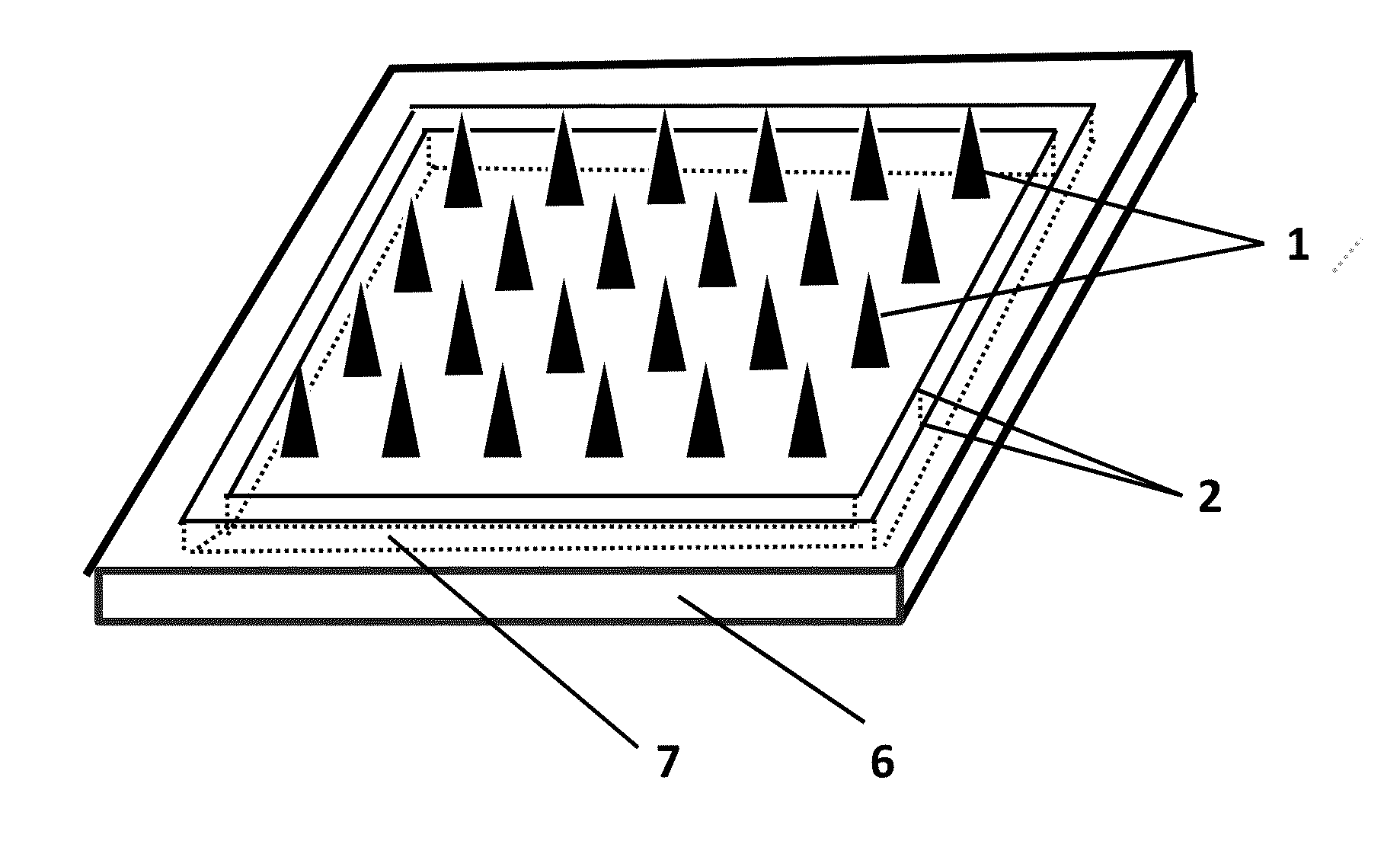

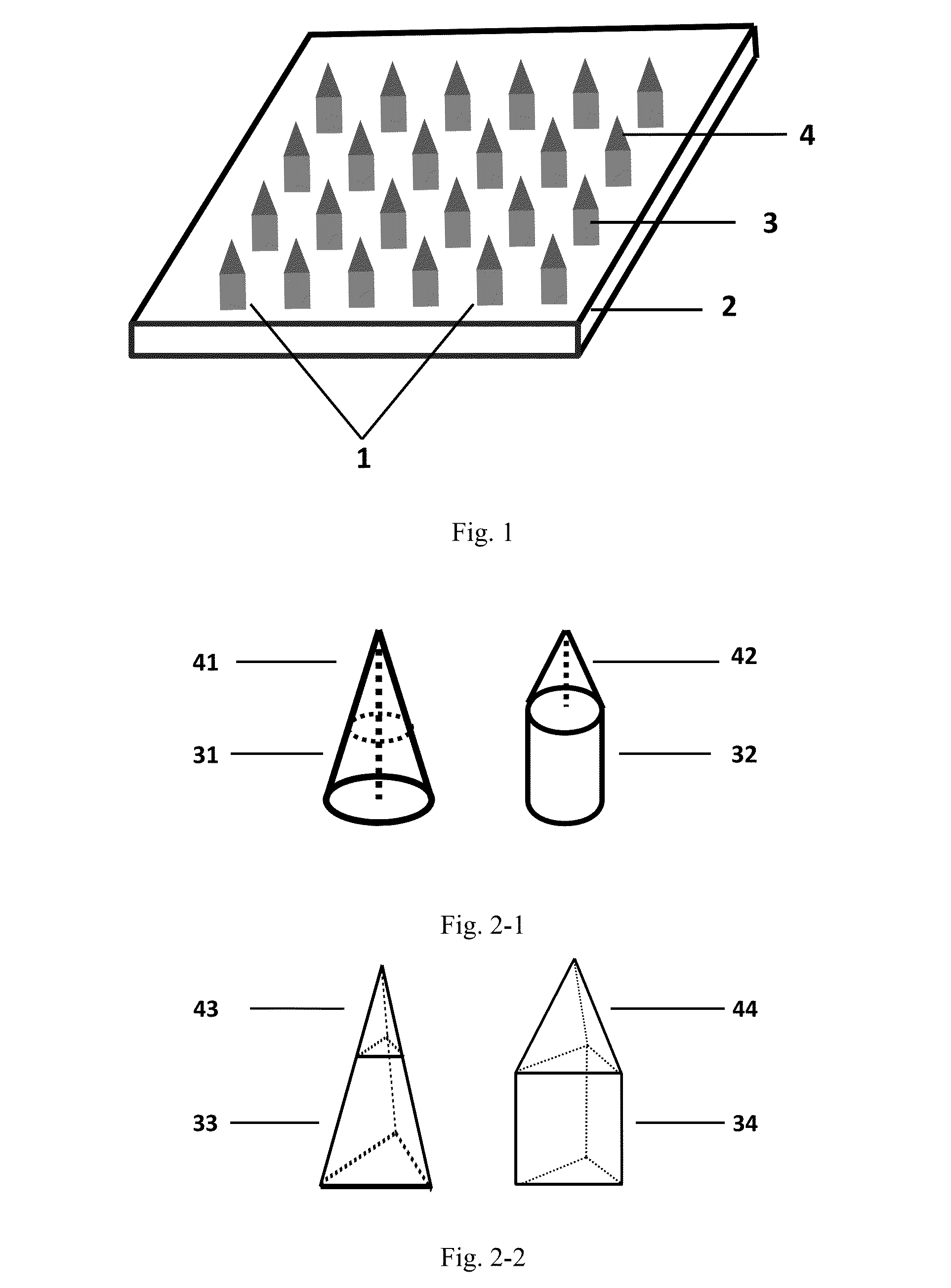

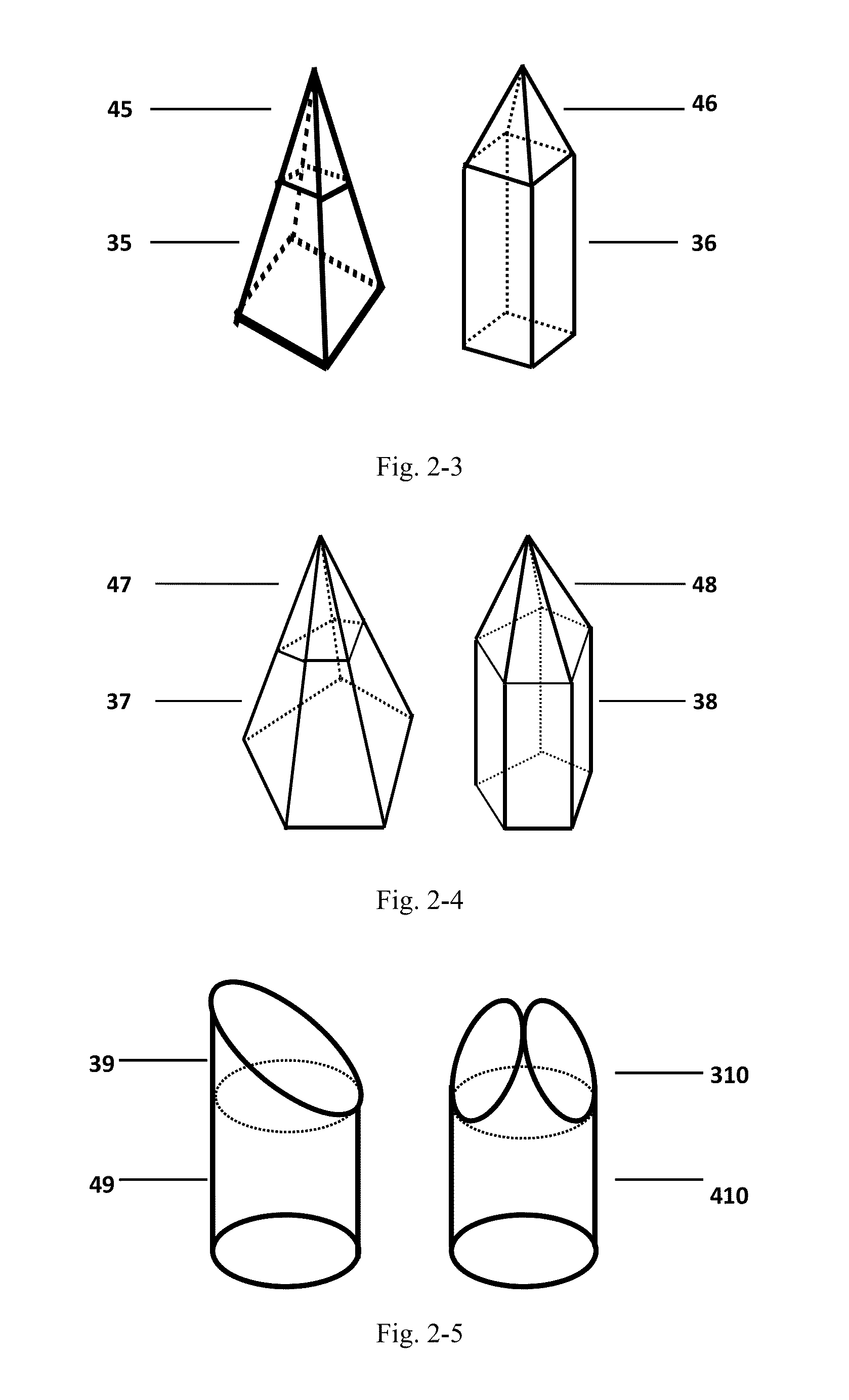

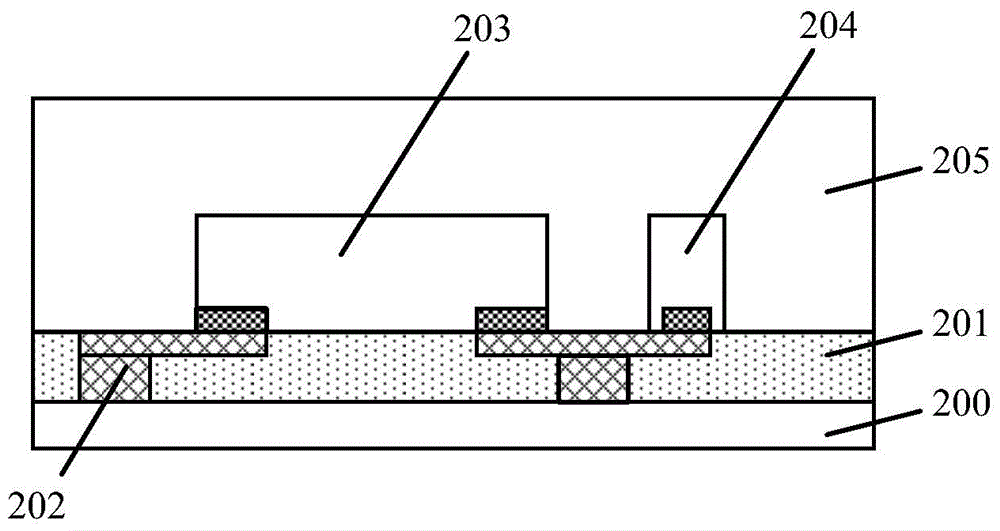

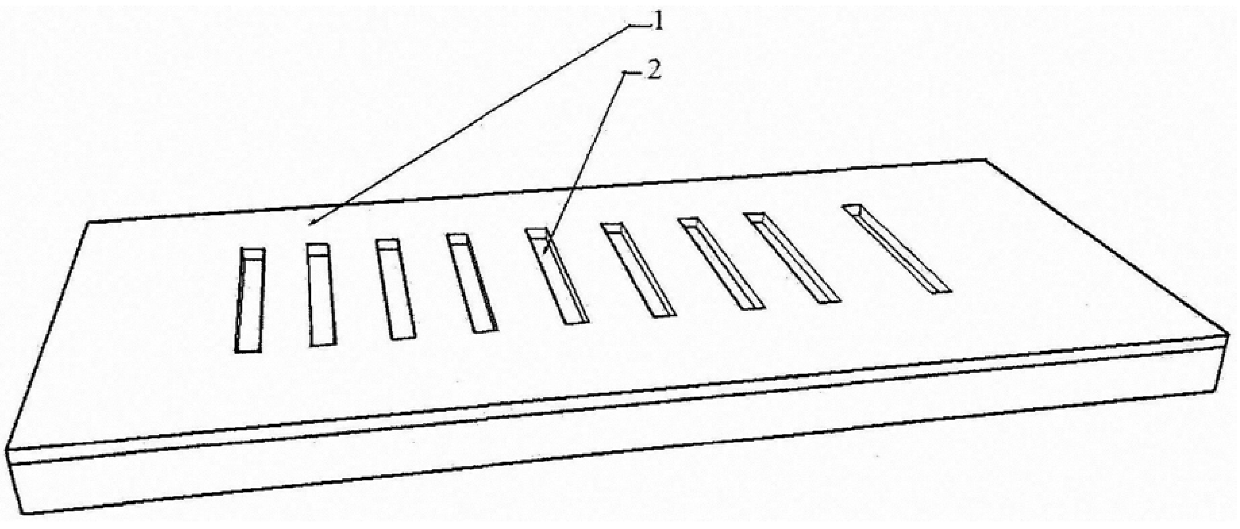

Polymer micro-needle array chip, preparation process and use thereof

InactiveUS20150030642A1High mechanical strengthEasy piercingSsRNA viruses negative-sensePeptide/protein ingredientsPolymer scienceHardness

The invention discloses a polymer micro-needle array chip, comprising a substrate and a micro-needle array standing thereon; the material for preparing the micro-needle array is a polyacrylamides polymer, with the molecular weight of 1.0×104-2.0×105, the Vickers hardness of 150-600 HV, and the impact strength of 5-30 J / m. The polymer micro-needle array chip has a high mechanical strength and a sharp needle tip, and it can easily dissolve or swell on contact with a water-containing environment, which helps the drug to be released slowly in the skin.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

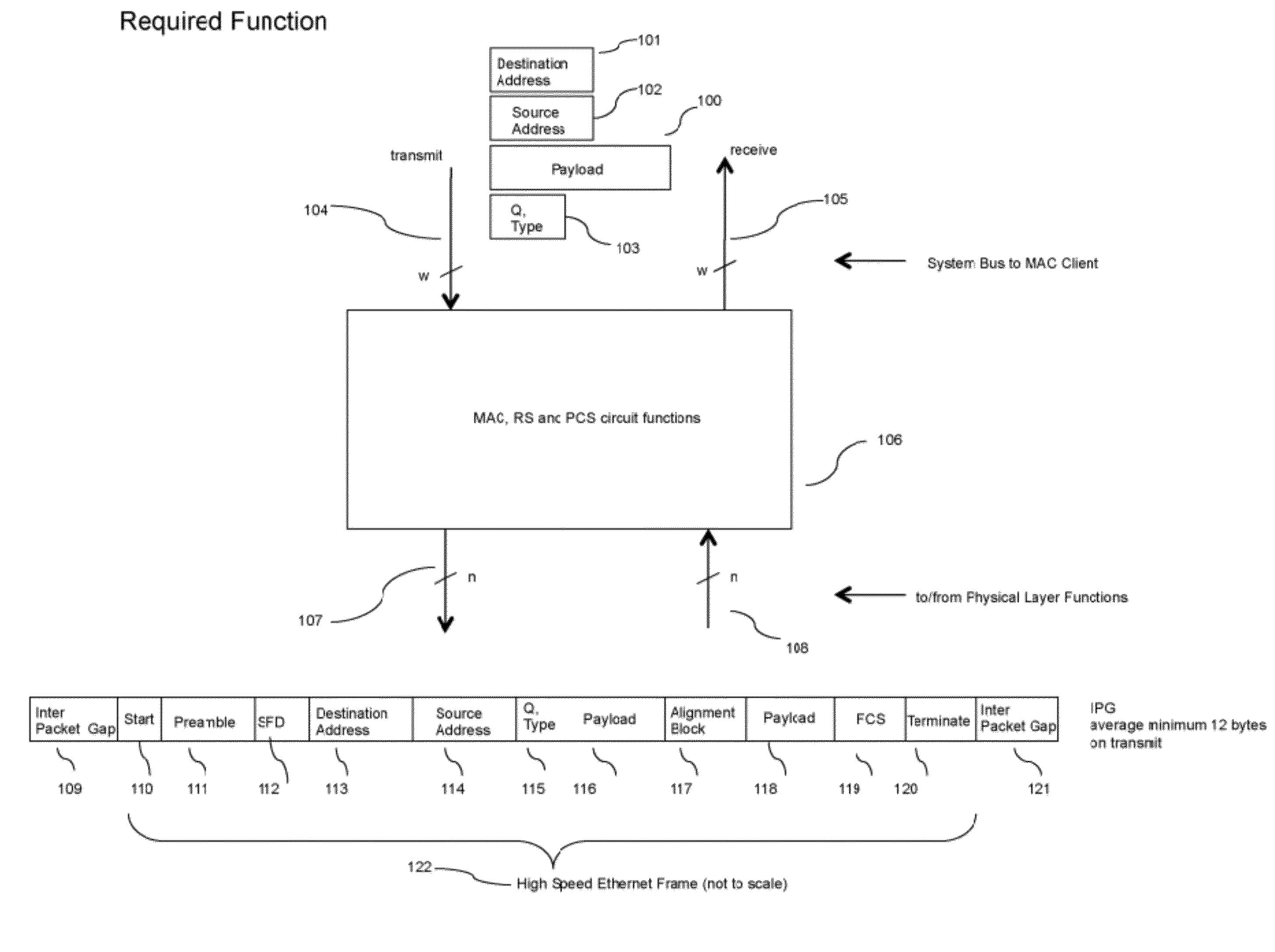

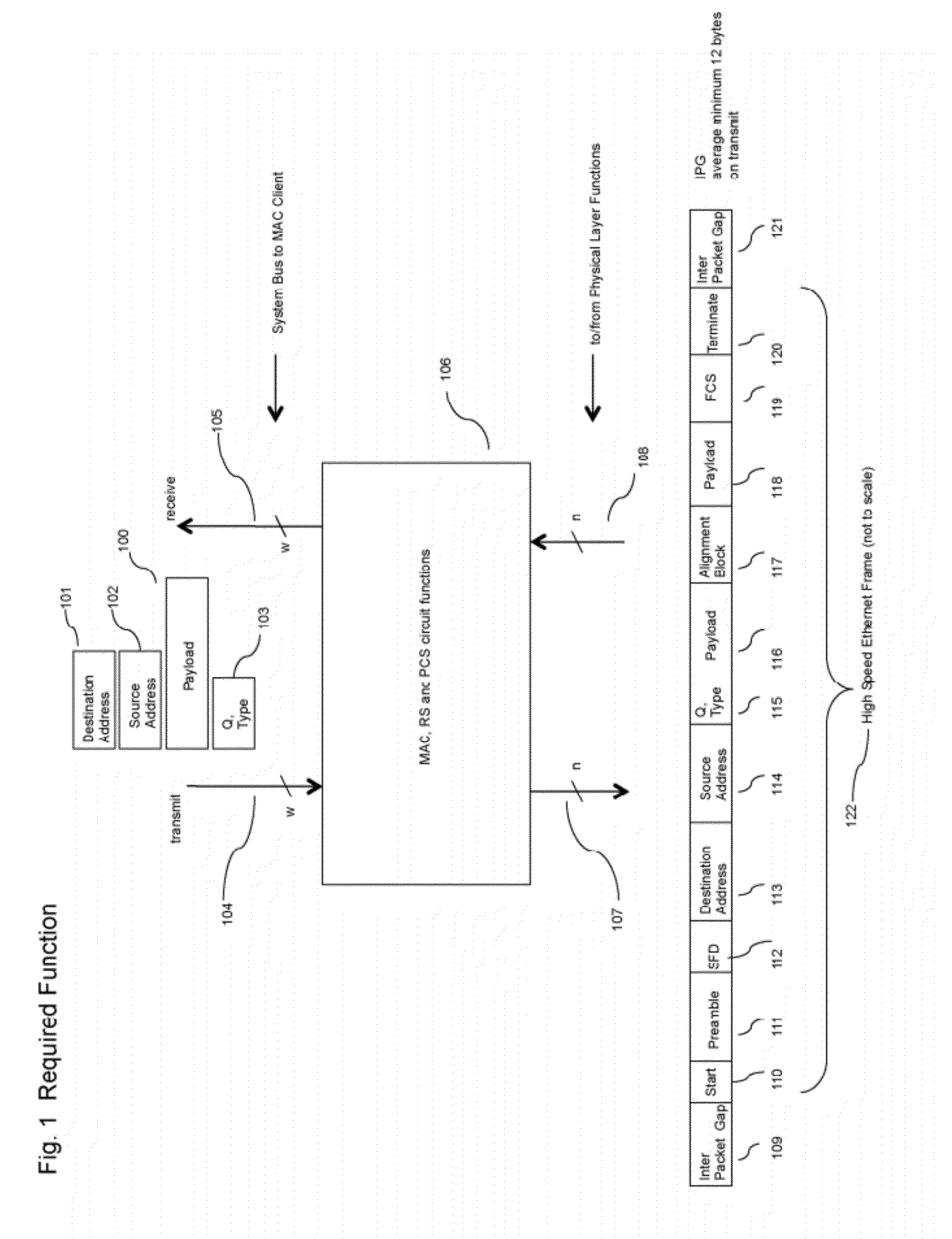

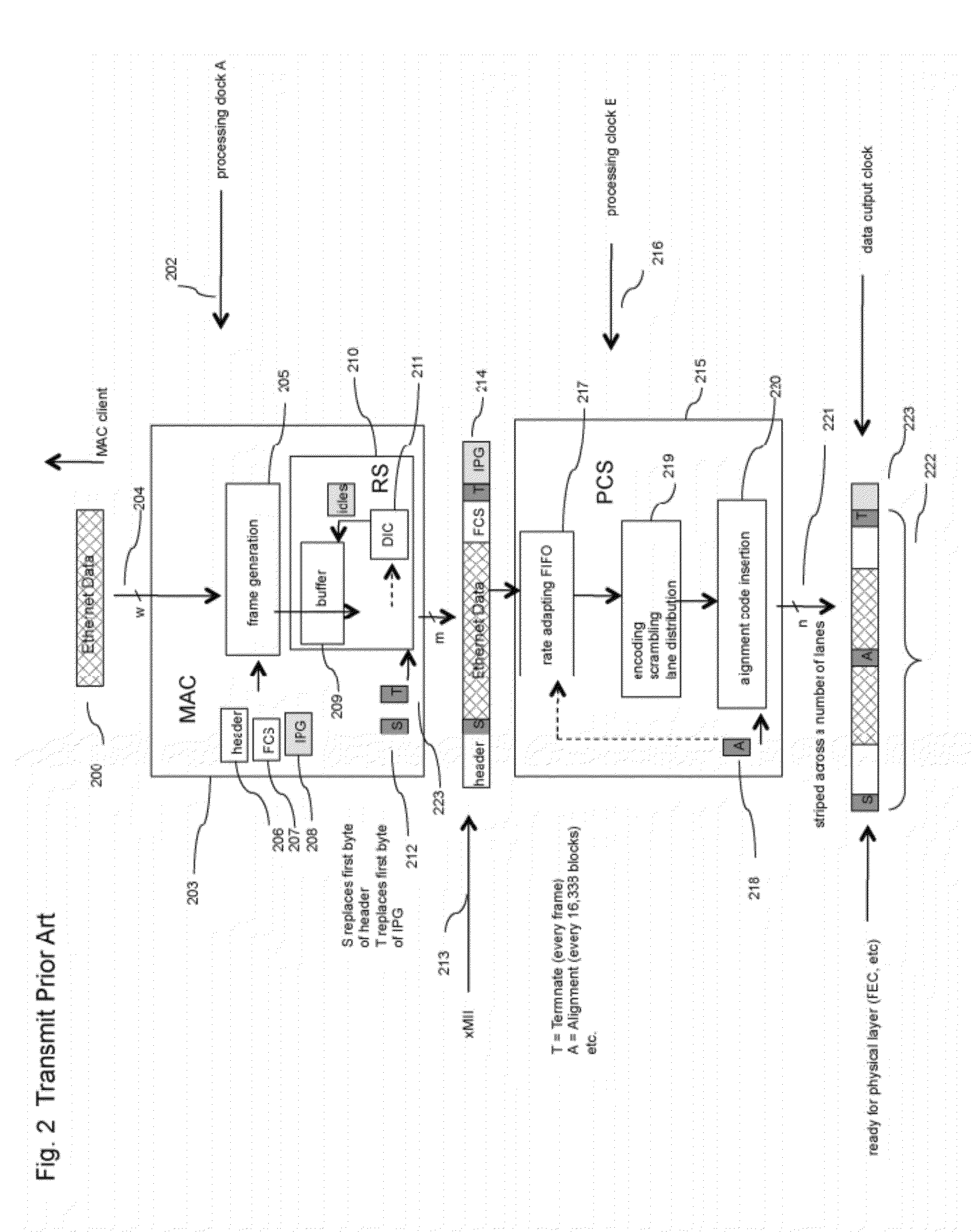

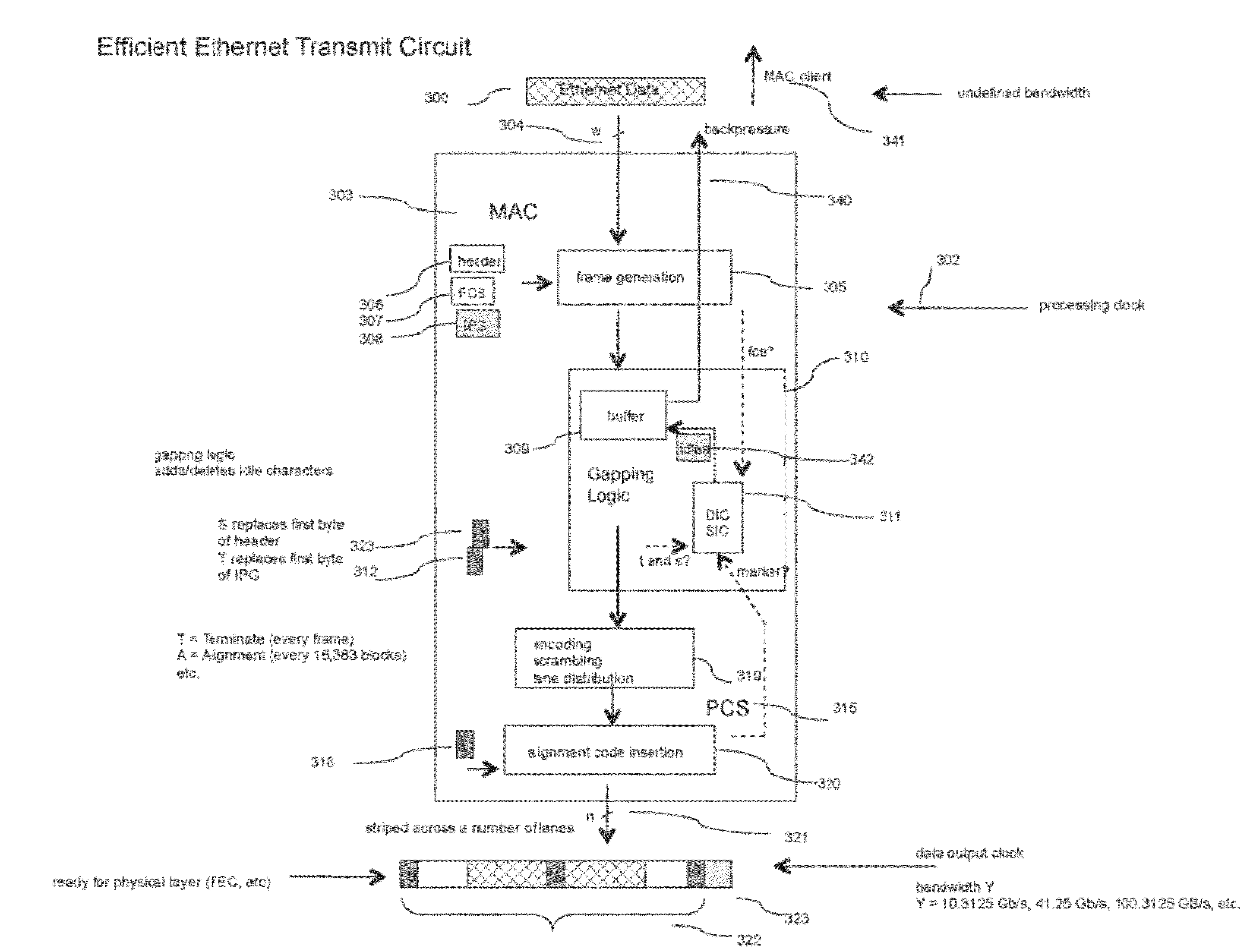

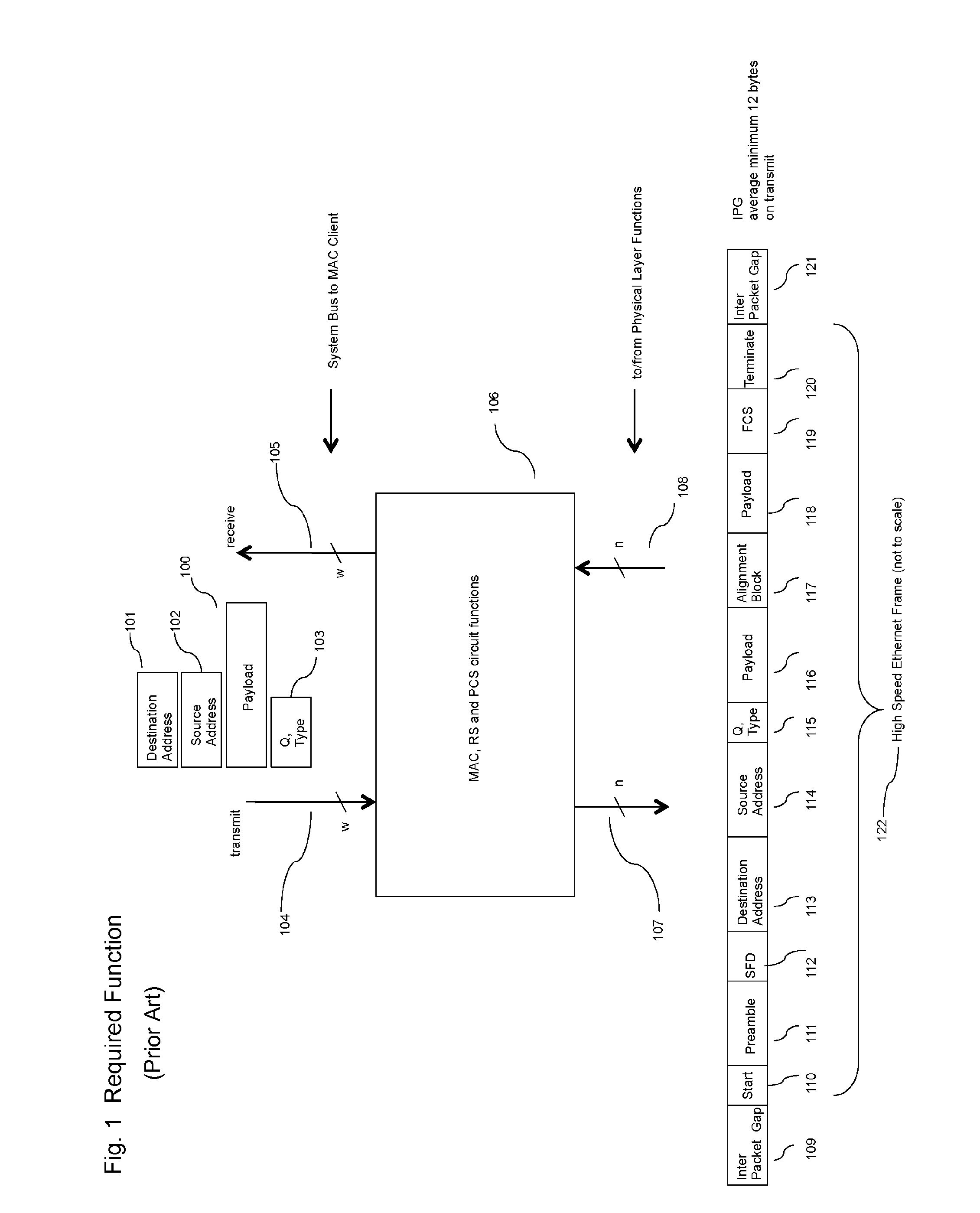

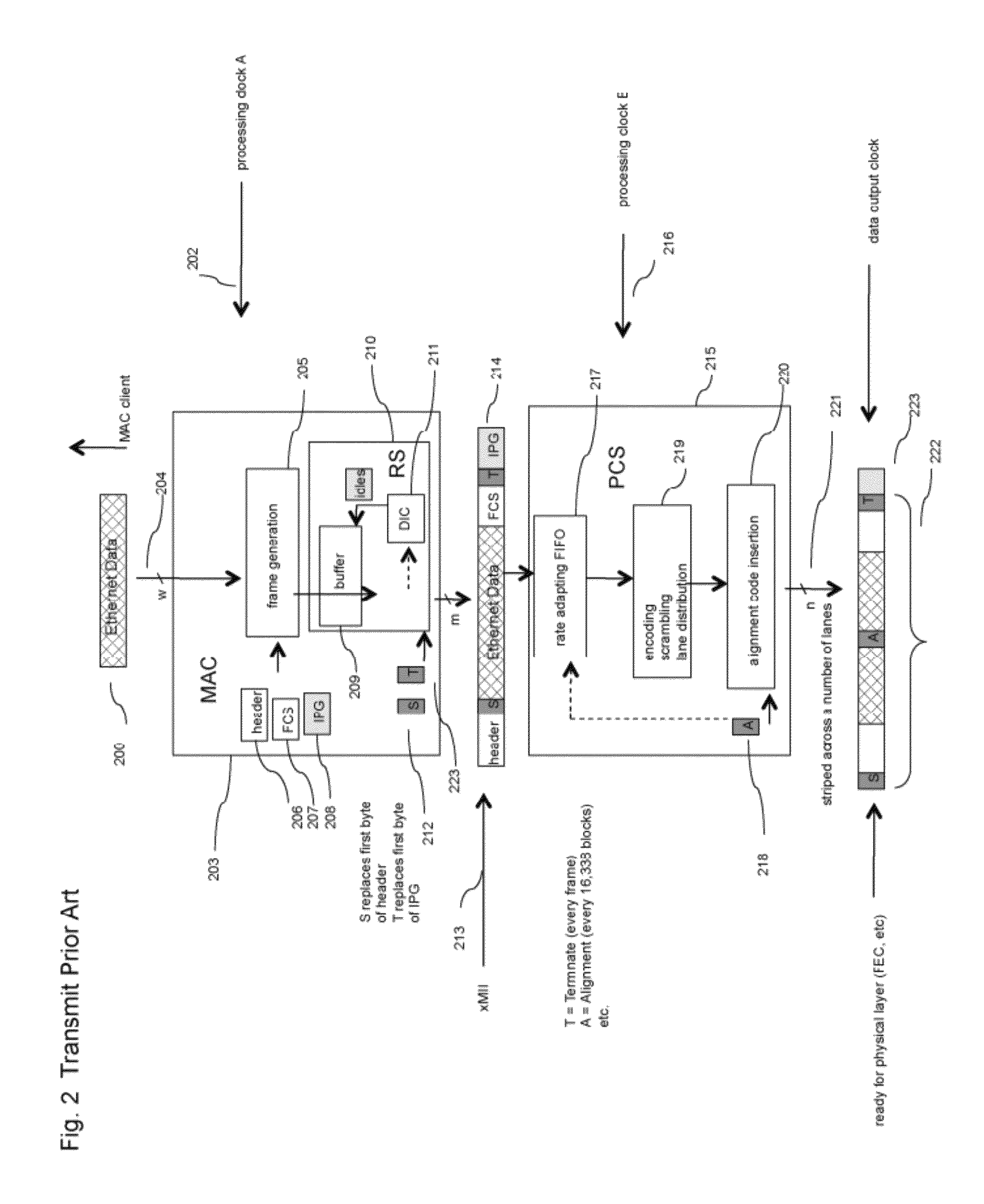

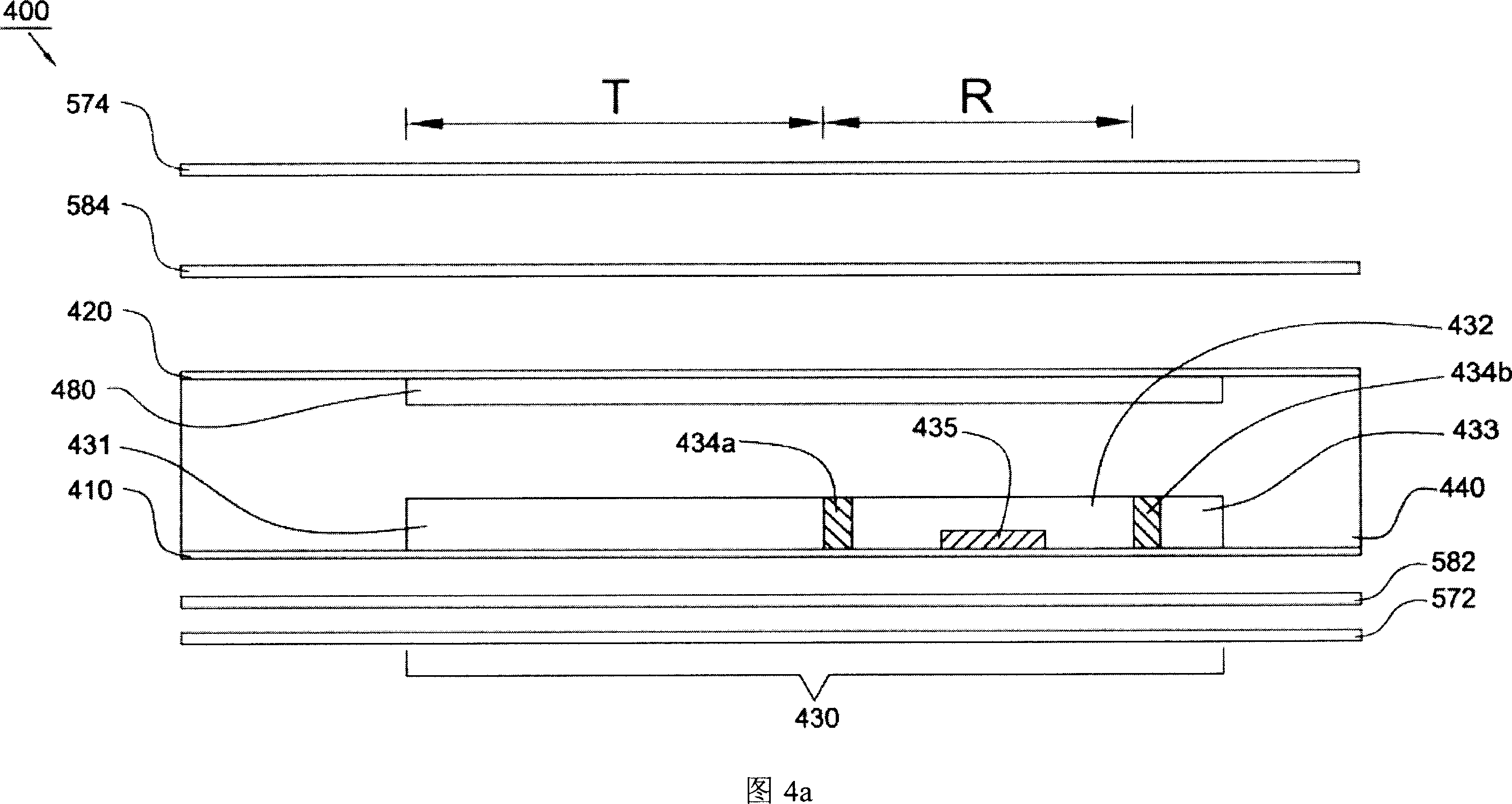

Packet Network Interface Apparatus and Method

ActiveUS20120236878A1Small circuitReduce circuitTime-division multiplexTransmissionTime domainNetwork interface device

A packet network interface apparatus includes a media access control (MAC) module for constructing a packet for transmission over a packet network and a physical coding sublayer (PCS) module for encoding the packet for transmission over a physical interface. An inter packet gap module located between the MAC module and the PCS module directly transfers data to the PCS module while maintaining a certain inter packet gap by deleting or inserting idle characters. The inter packet gap module has at least one memory module for temporary storage of packet data. The modules preferably operate in a common time domain.

Owner:XILINX INC

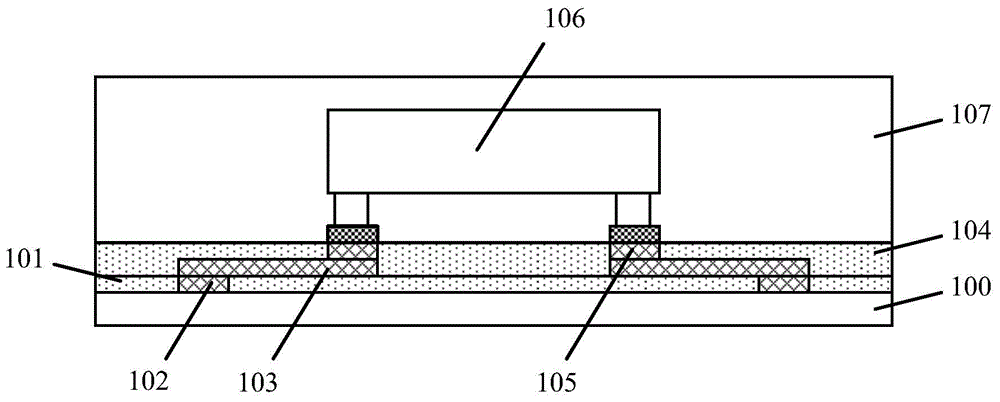

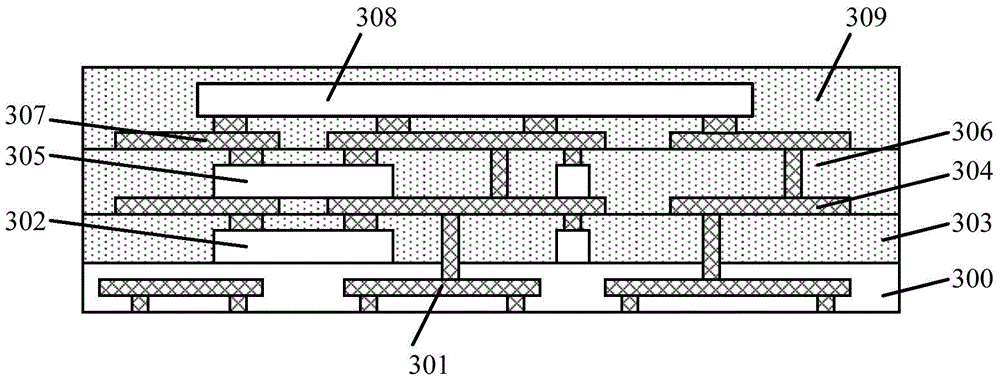

Chip packaging method and chip packaging structure

InactiveCN104835808AImprove bindingSmall sizeSemiconductor/solid-state device detailsSolid-state devicesEngineeringStructural dimension

The invention provides a chip packaging method and a chip packaging structure, wherein the chip packaging method comprises the steps of providing a first chip which comprises a first surface and a second surface that oppose each other, wherein the first surface of the first chip is provided with a plurality of first pads; providing a second chip with a third surface and a fourth surface that oppose each other, wherein the third surface of the second chip is provided with a plurality of second pads and the area of the second chip is larger than that of the first chip; providing a carrier plate; combining the fourth surface of the second chip with the surface of the carrier plate, wherein the plurality of second pads are arranged outside the combining area between the first chip and the second chip; forming a sealing material layer on the surface of the carrier plate, wherein the sealing material layer packages the first chip and the second chip; and forming a first conductive structure and a second conductive structure in the sealing material layer, wherein the first conductive structure is electrically connected with the first pads and the second conductive structure is electrically connected with the second pads. A package which is formed according to the chip packaging method has advantages of reduced structural dimension, improved stability and improved reliability.

Owner:CHINA WAFER LEVEL CSP

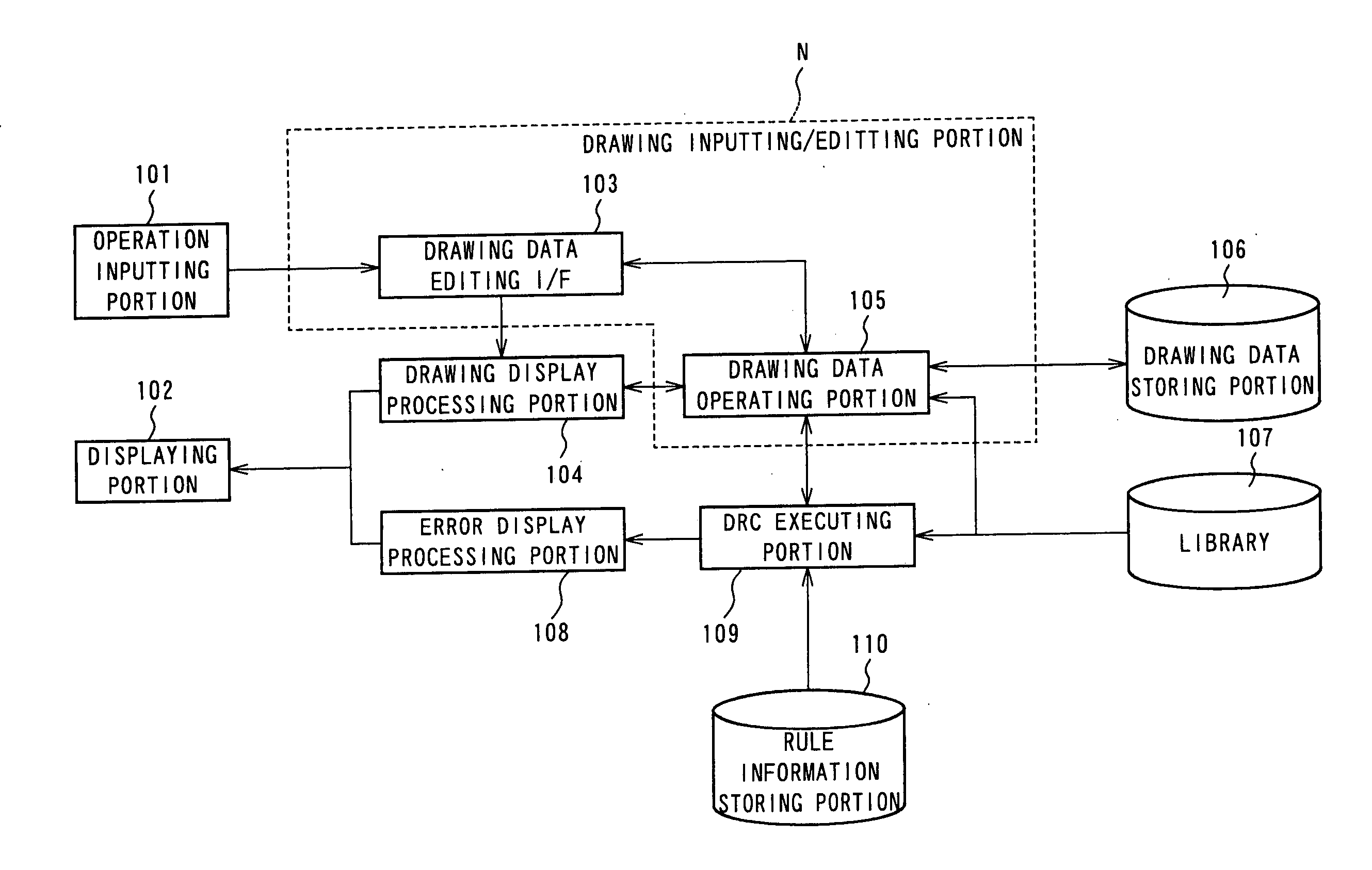

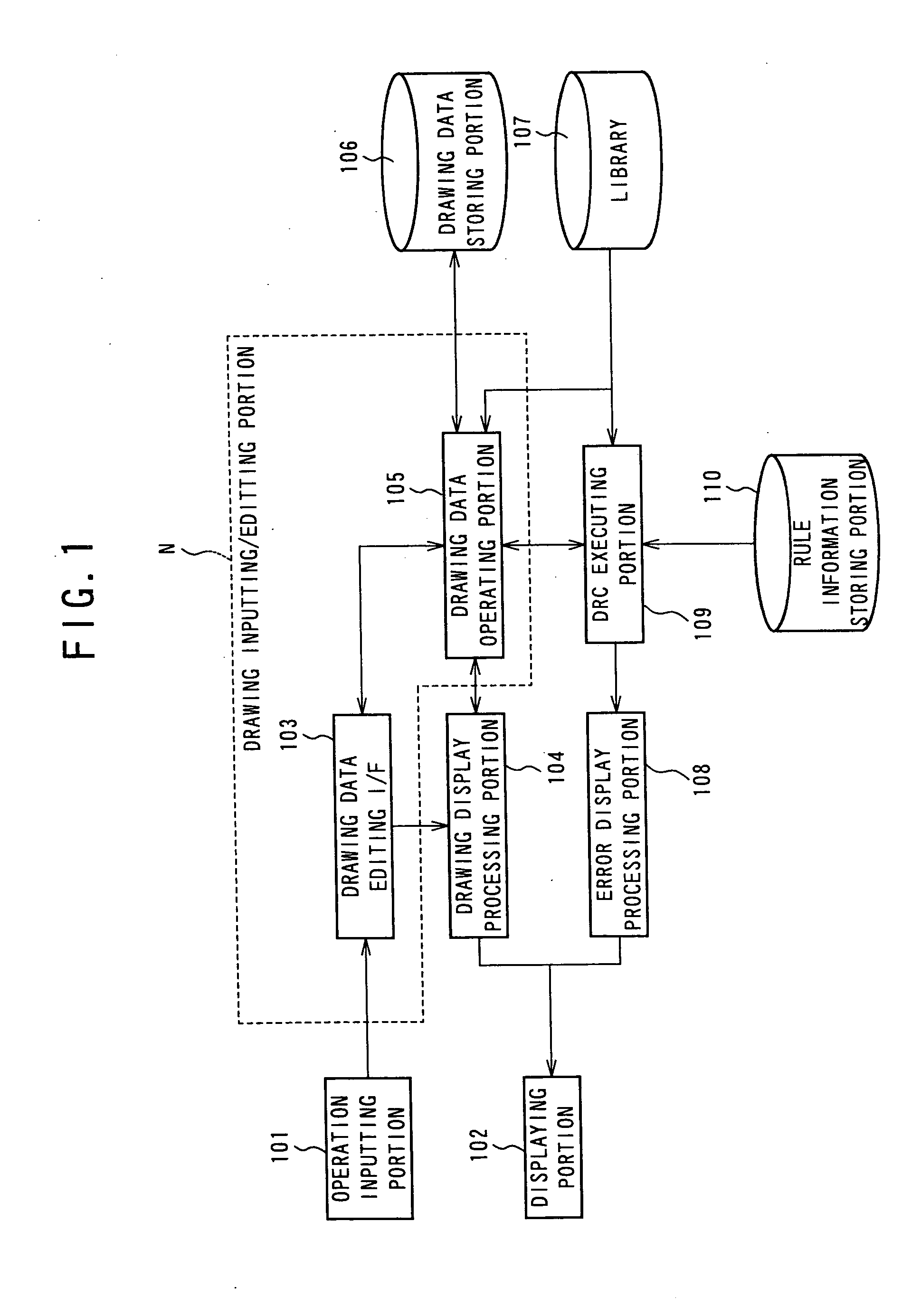

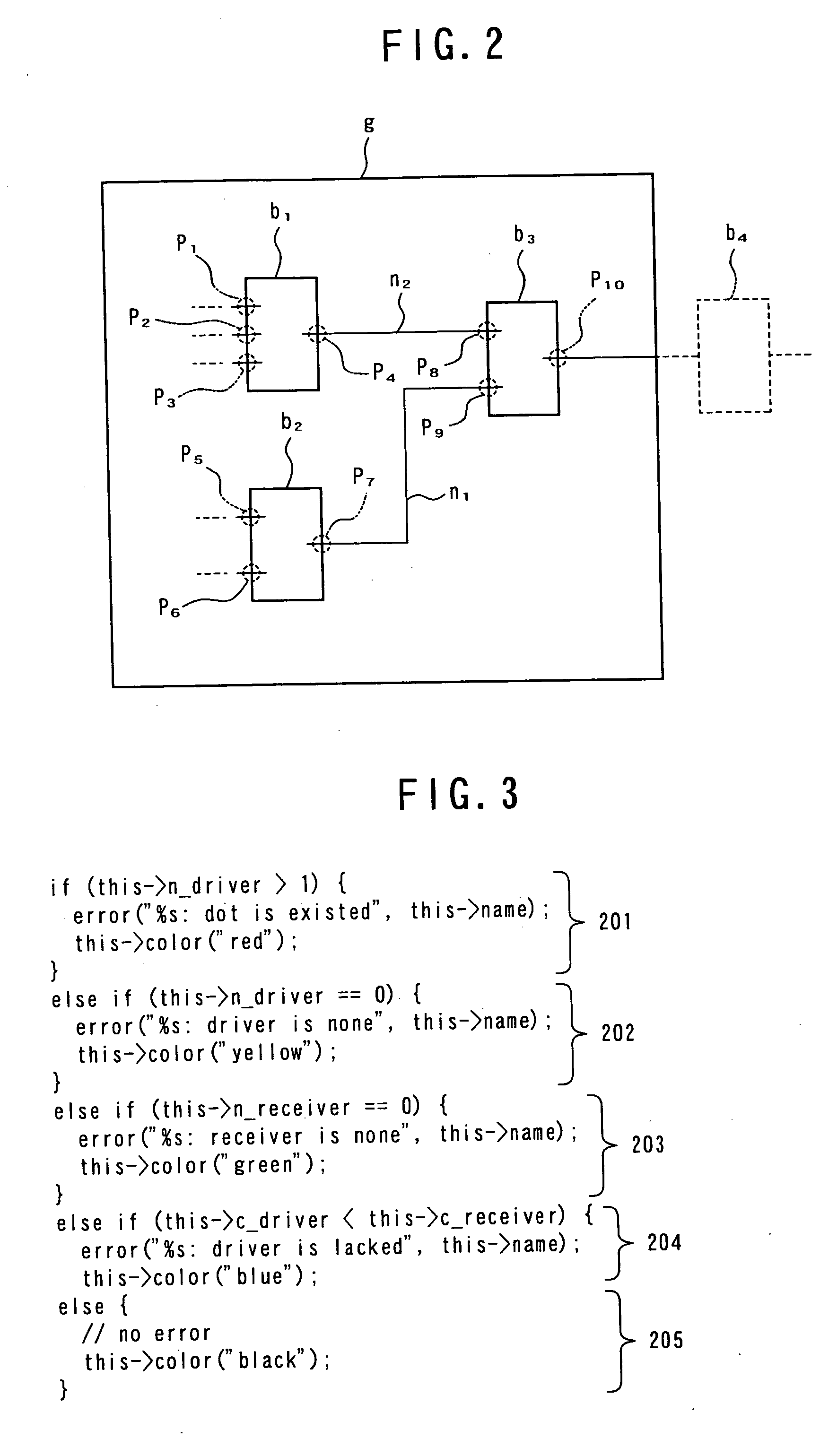

Drawing input apparatus, drawing input program and drawing input method

InactiveUS20050216835A1Improve drawing efficiencyReduce the burden onDrawing from basic elementsComputer aided designComputer scienceInformation storage

The present invention as disclosed hereby is to provide a drawing input apparatus, drawing input program and drawing input method. The drawing input apparatus comprising: a drawing inputting / editing portion adapted to input or edit drawing data; a rule information storing portion adapted to store therein rule information defining rules for inputting or editing the drawing data; and a rule checking portion adapted to check by using the rule information a part which is present in the drawing data and which is modified based on a predetermined operation on the condition that said drawing inputting / editing portion executes such a predetermined operation.

Owner:FUJITSU LTD

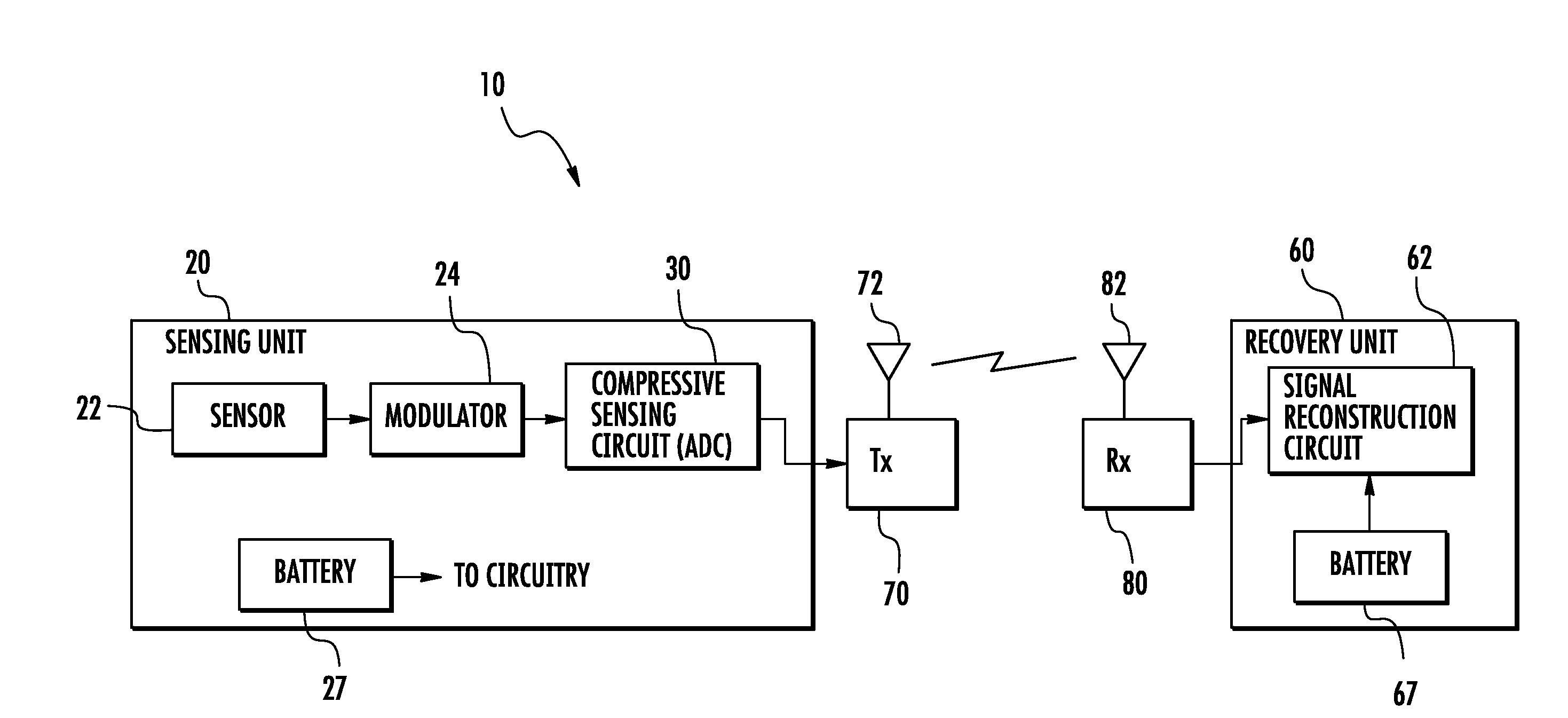

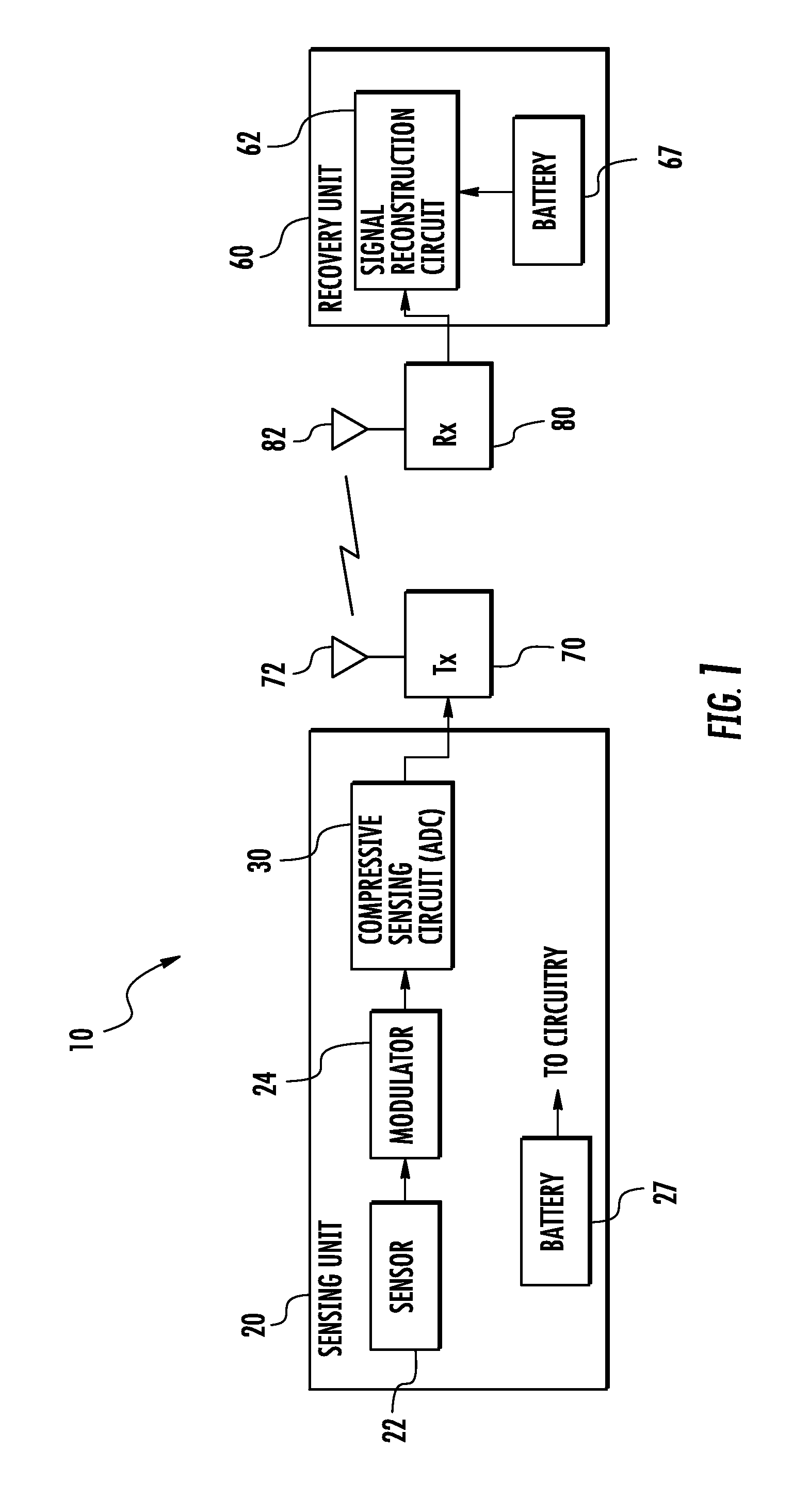

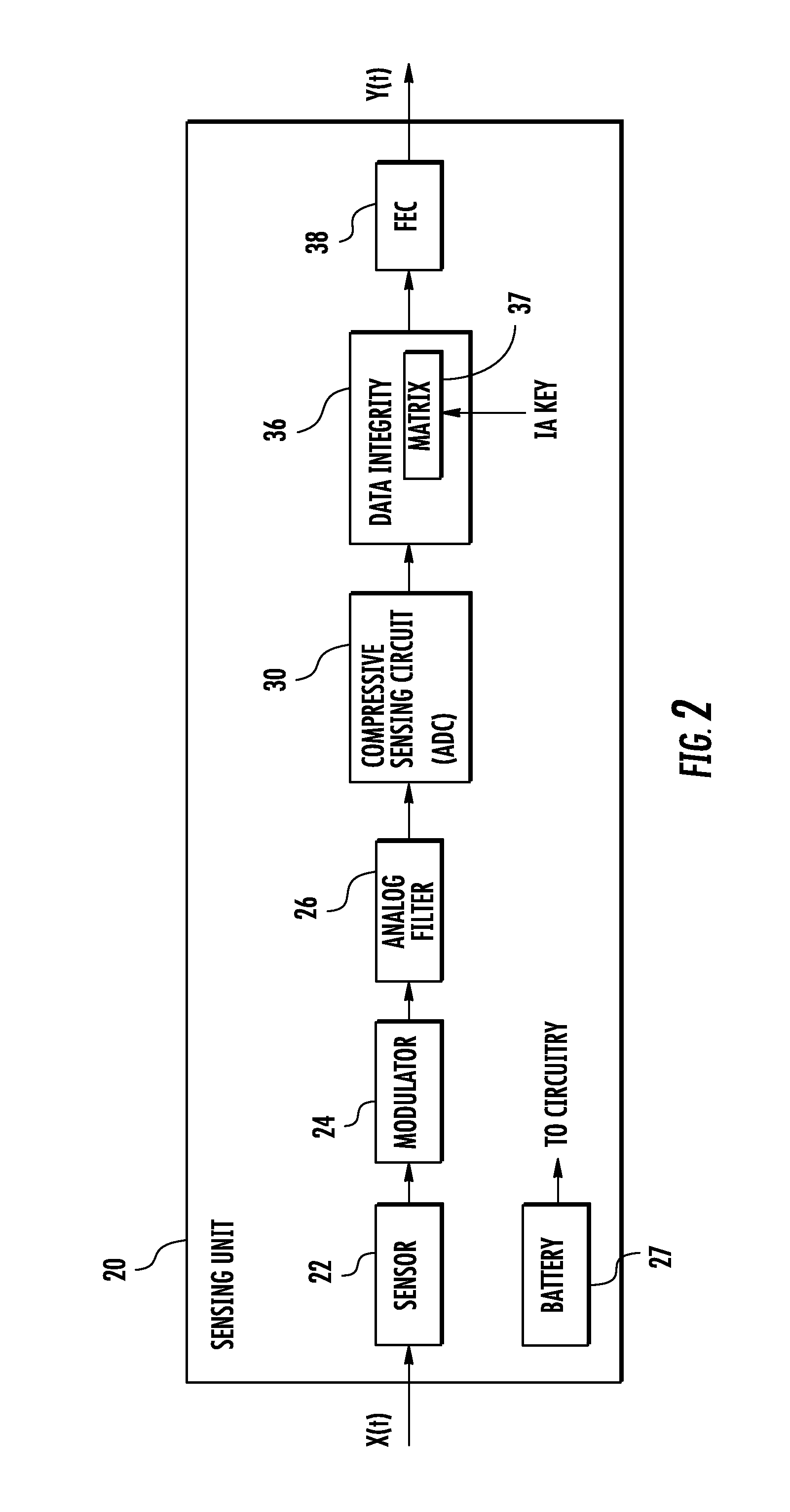

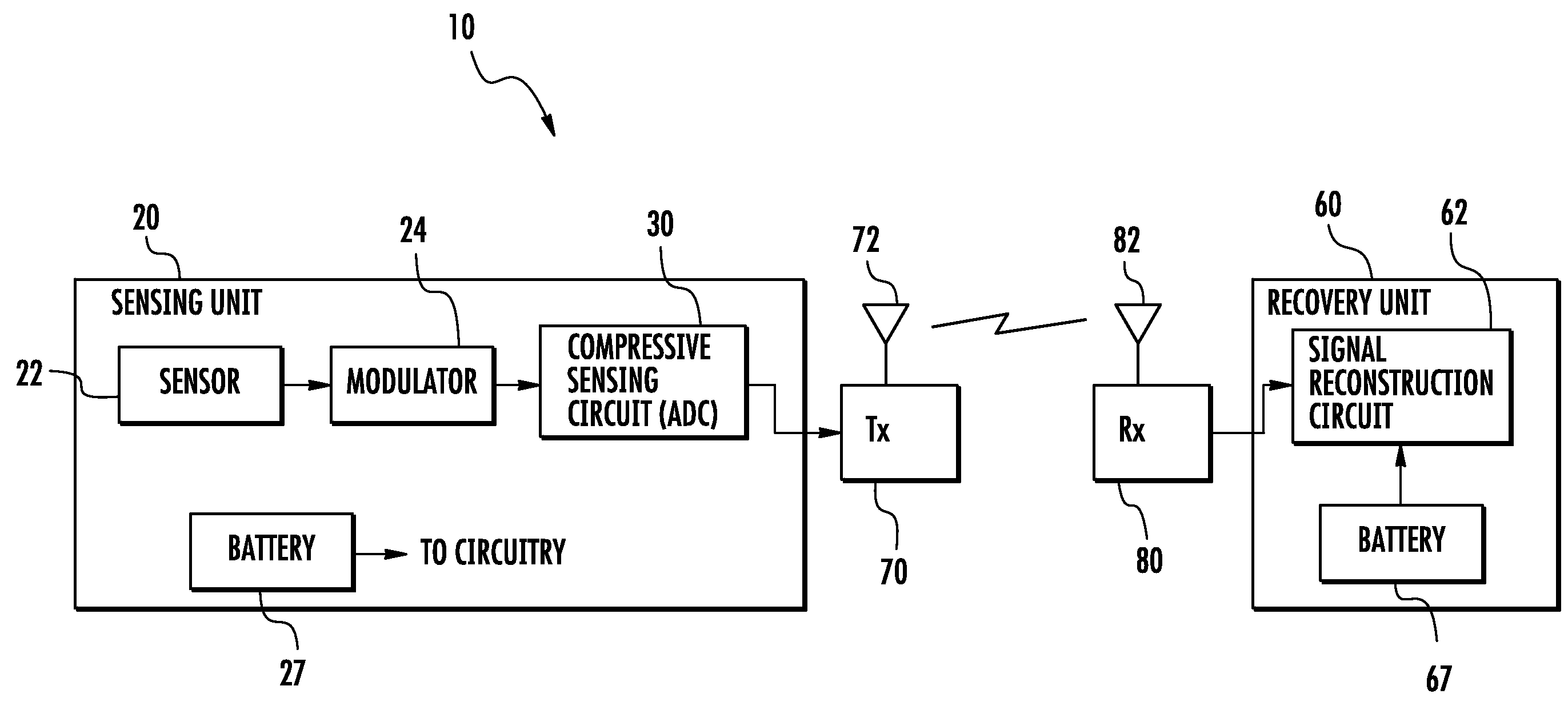

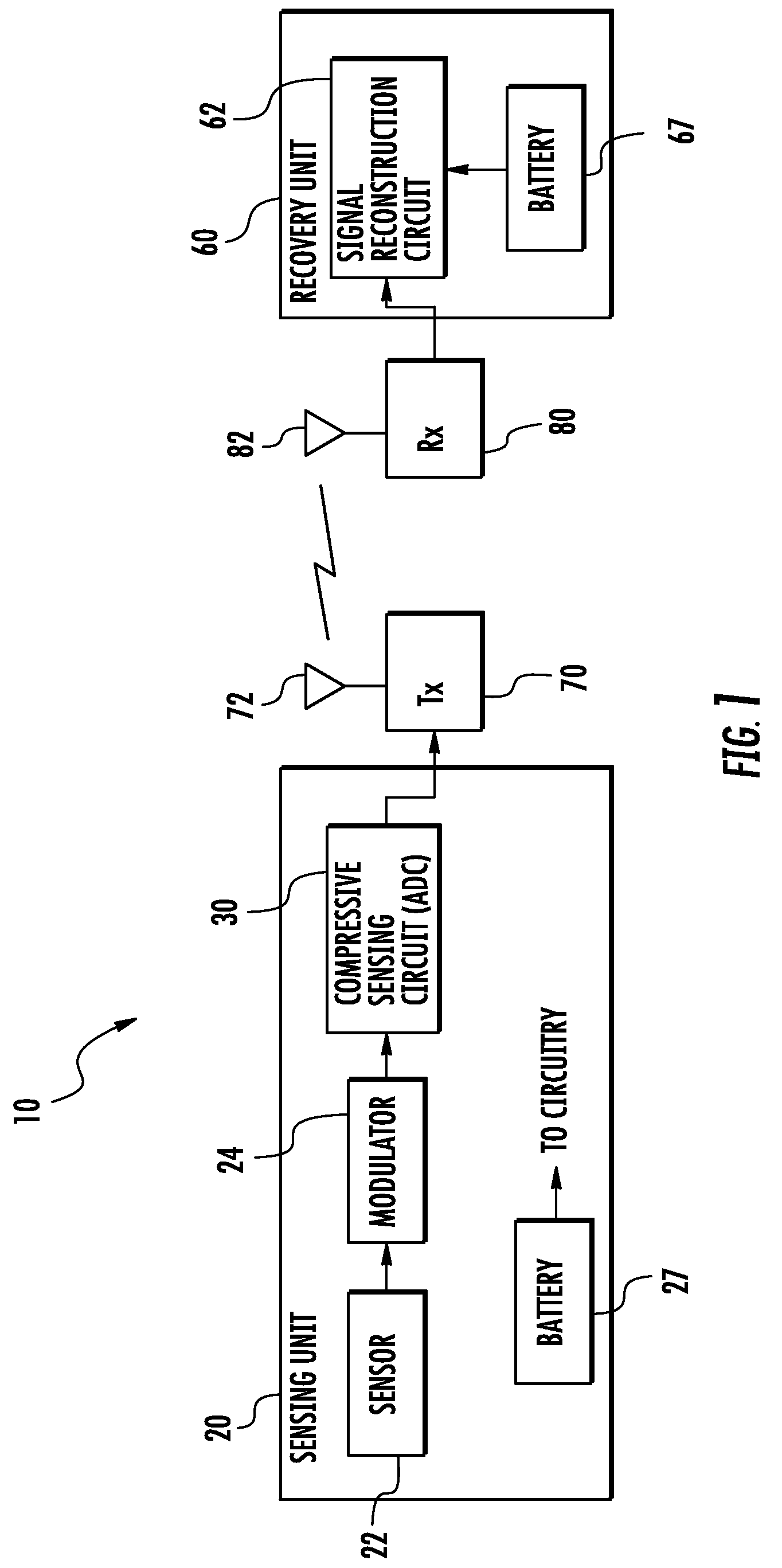

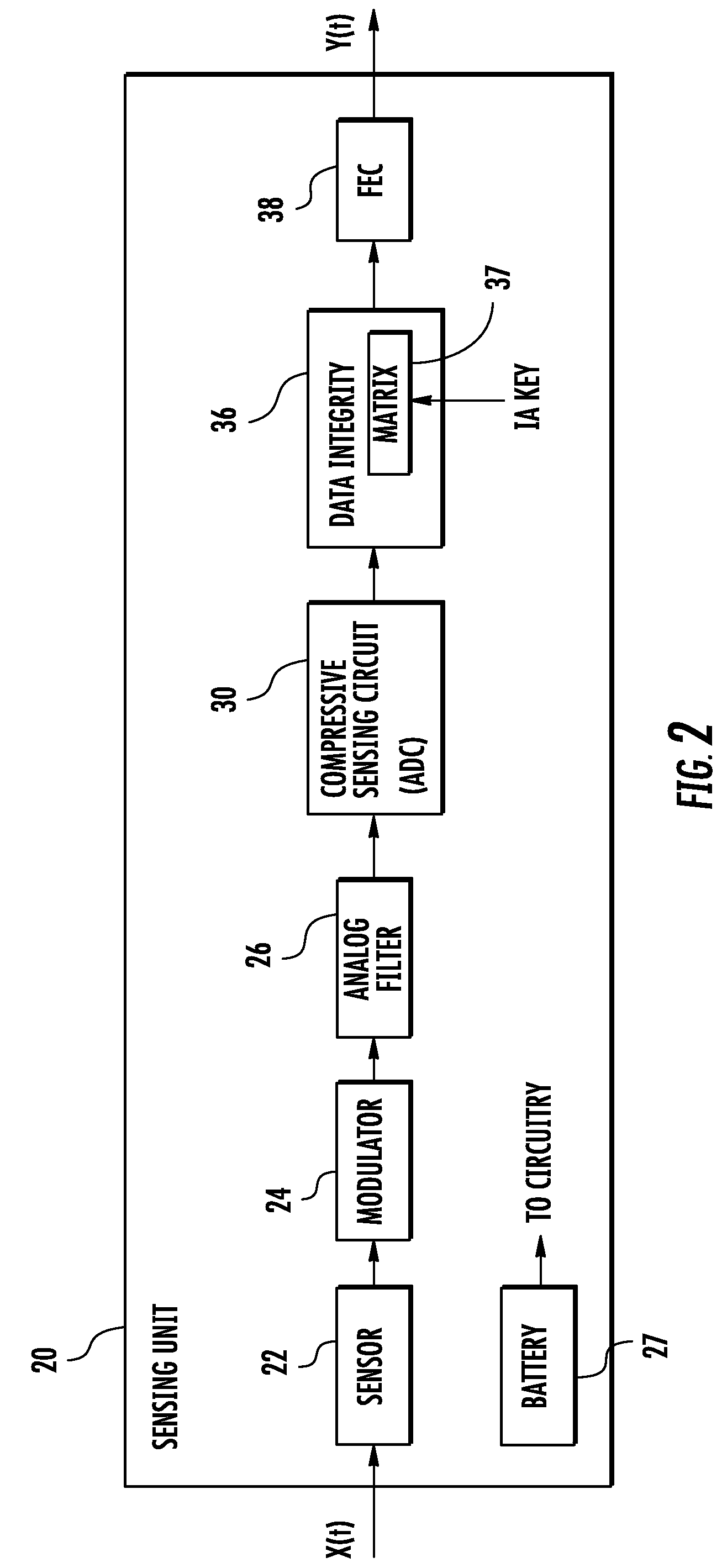

System with sub-nyquist signal acquisition and transmission and associated methods

ActiveUS20130149959A1Efficiently signaledReduce total powerNear-field transmissionElectric signal transmission systemsAnalog signalCorrelation method

A sensing and recovery system includes a sensing unit and a recovery unit coupled together. The sensing unit includes a sensor to generate a bandlimited continuous time analog signal, and a modulator coupled to the sensor to generate a modulated analog signal based upon modulation of the bandlimited continuous time analog signal at a modulating rate at least equal to a Nyquist rate for the bandlimited continuous time analog signal. A compressive sensing circuit is coupled to the modulator to generate a compressed sensed signal based upon conversion of the modulated analog signal at a sampling rate less than the Nyquist rate. The recovery unit recovers the bandlimited continuous time analog signal from the compressed sensed signal.

Owner:HARRIS CORP

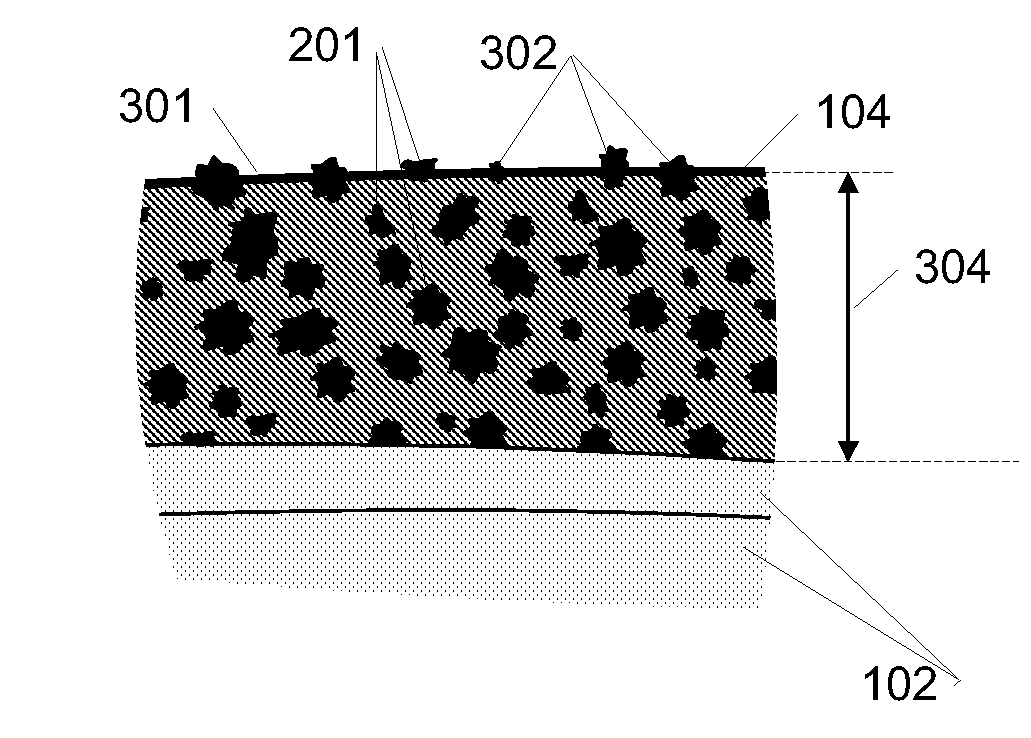

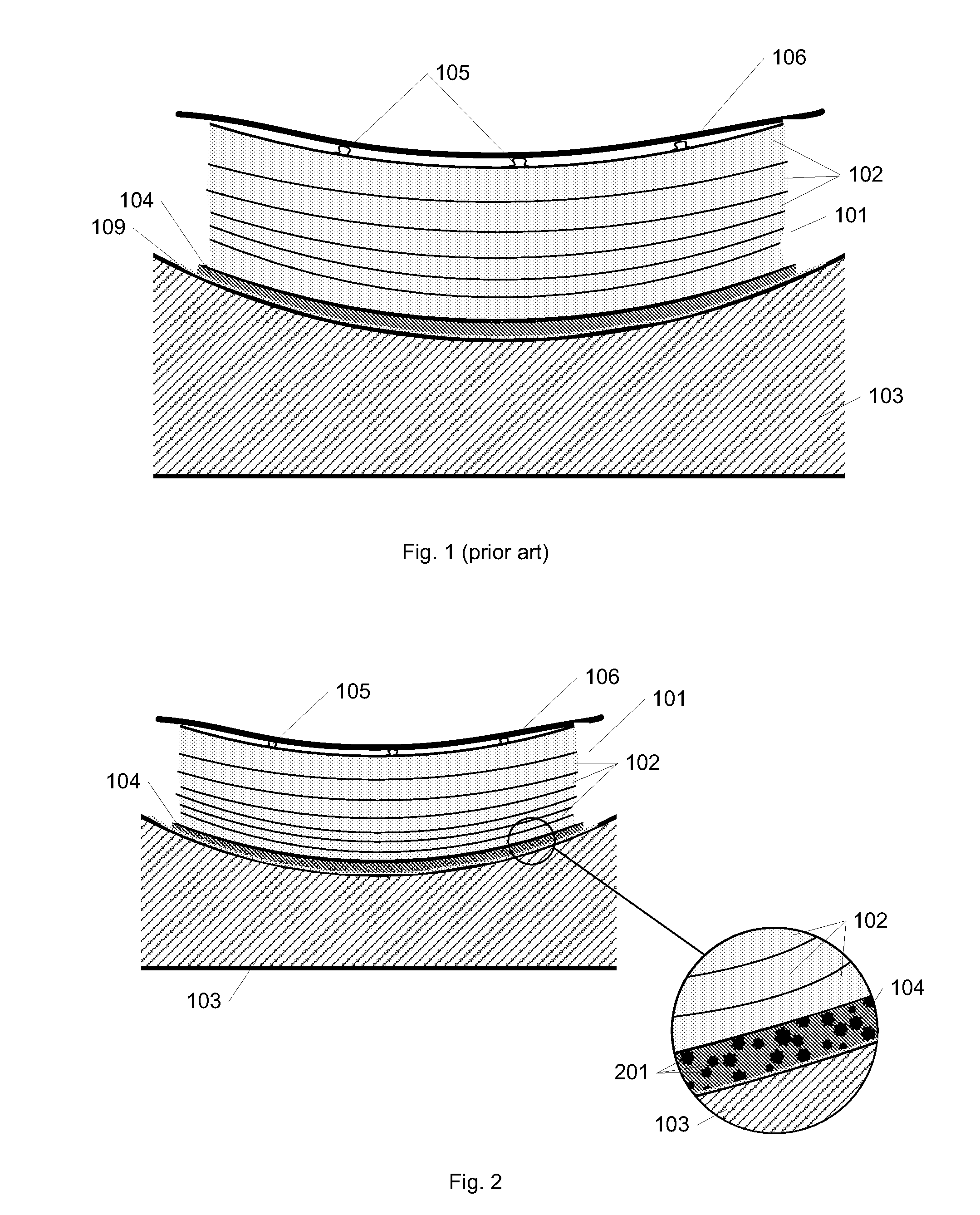

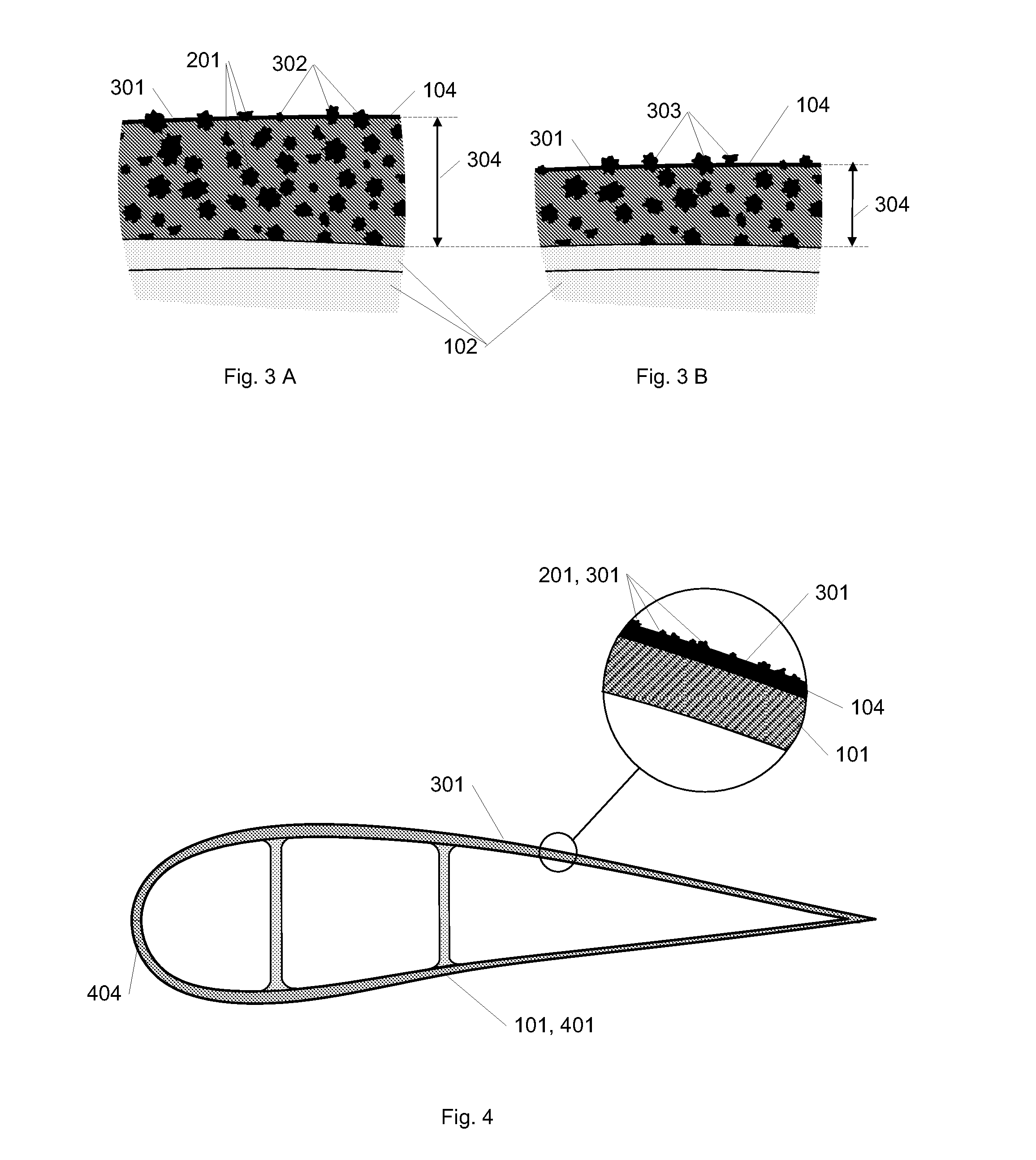

Regenerating surface properties for composites

ActiveUS20110129646A1Reduce noiseReduce fluid resistanceMouldsFinal product manufacturePolyresinGelcoat

This invention relates to a method for manufacturing a composite member, where a number of different material layers including at least one layer of gelcoat are applied in a mould, and where resin is applied for joining of the layers. The method is new in that particles are added to the gelcoat, whereby the gelcoat comprising such particles forms an outermost layer on at least a part of the manufactured composite member. Hereby is obtained a composite with a hydrophobic and lotus-like surface yielding good self-cleaning properties and which is on the same time self-regenerating. The invention furthermore relates to composite members comprising such a gelcoat layer with particles and to the use of gelcoat comprising particles for giving regenerating self-cleaning properties.

Owner:LM GLASSFIBER

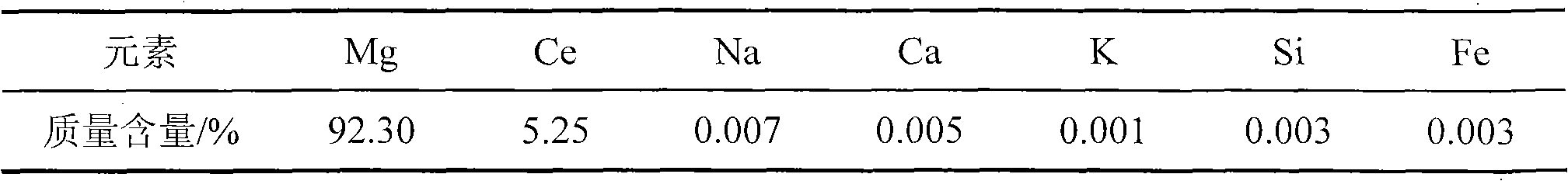

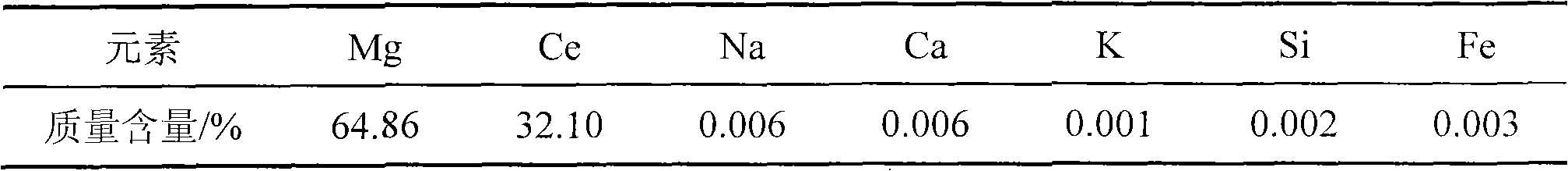

Method for electrolytically preparing magnesium-rare earth by using hydrated magnesium chloride and rare earth chloride

The invention relates to a method for electrolytically preparing magnesium-rare earth by using hydrated magnesium chloride and rare earth chloride, which is characterized by taking MgCl2.2H2O and CeCl3.3H2O or MgCl2.2H2O and NdCl3.3H2O as raw materials, taking a system of MgCl2-NaCl-KCl-CeCl3 or a system of MgCl2-NaCl-KCl-NdCl3 as an electrolyte, taking a molybdenum rod as a subsidence cathode and black lead as an anode, carrying out DC electrolyte under the condition with the voltage of 4.0-8.0V and the temperature of 680 -800 DEG C, and obtaining magnesium-rare earth. The invention uses incomplete dehydrated hydrated magnesium chloride and incomplete dehydrated rare earth chloride as the raw materials to carry out the electrolyte, and avoids the process of removing the constituent water of crystal in the traditional method, so that the processes can be simplified, and simultaneously, the cost of the raw materials and production can be reduced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

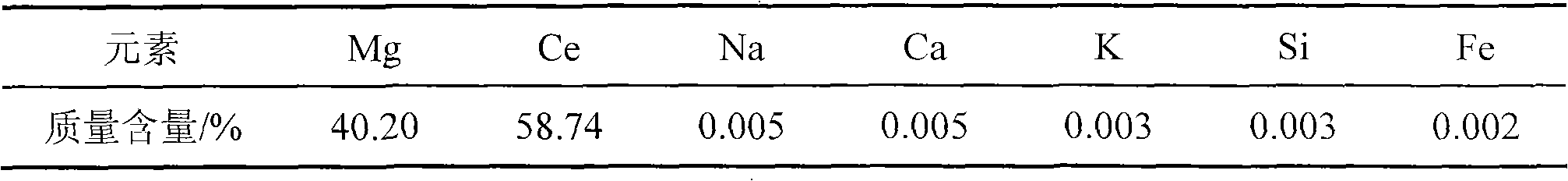

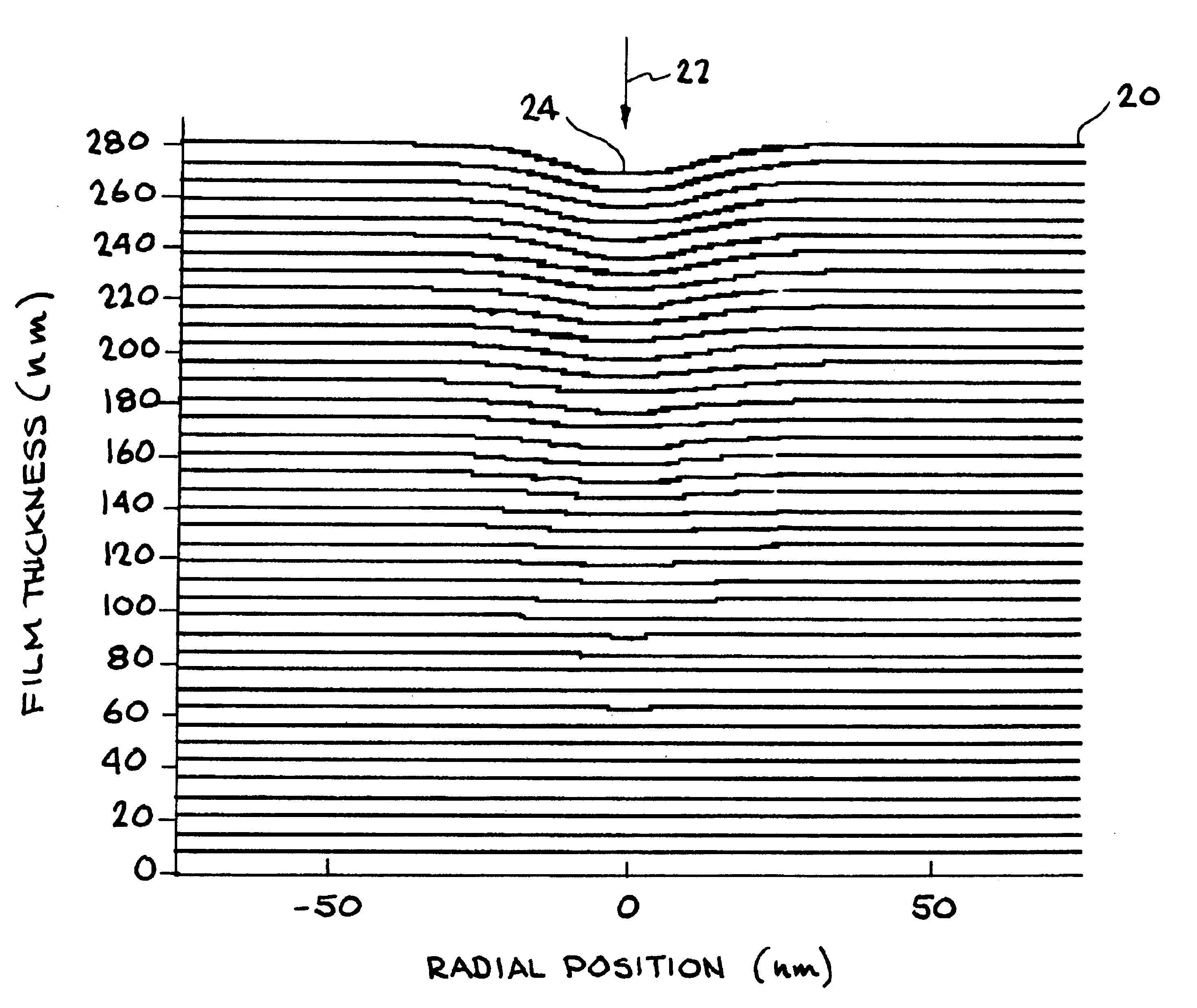

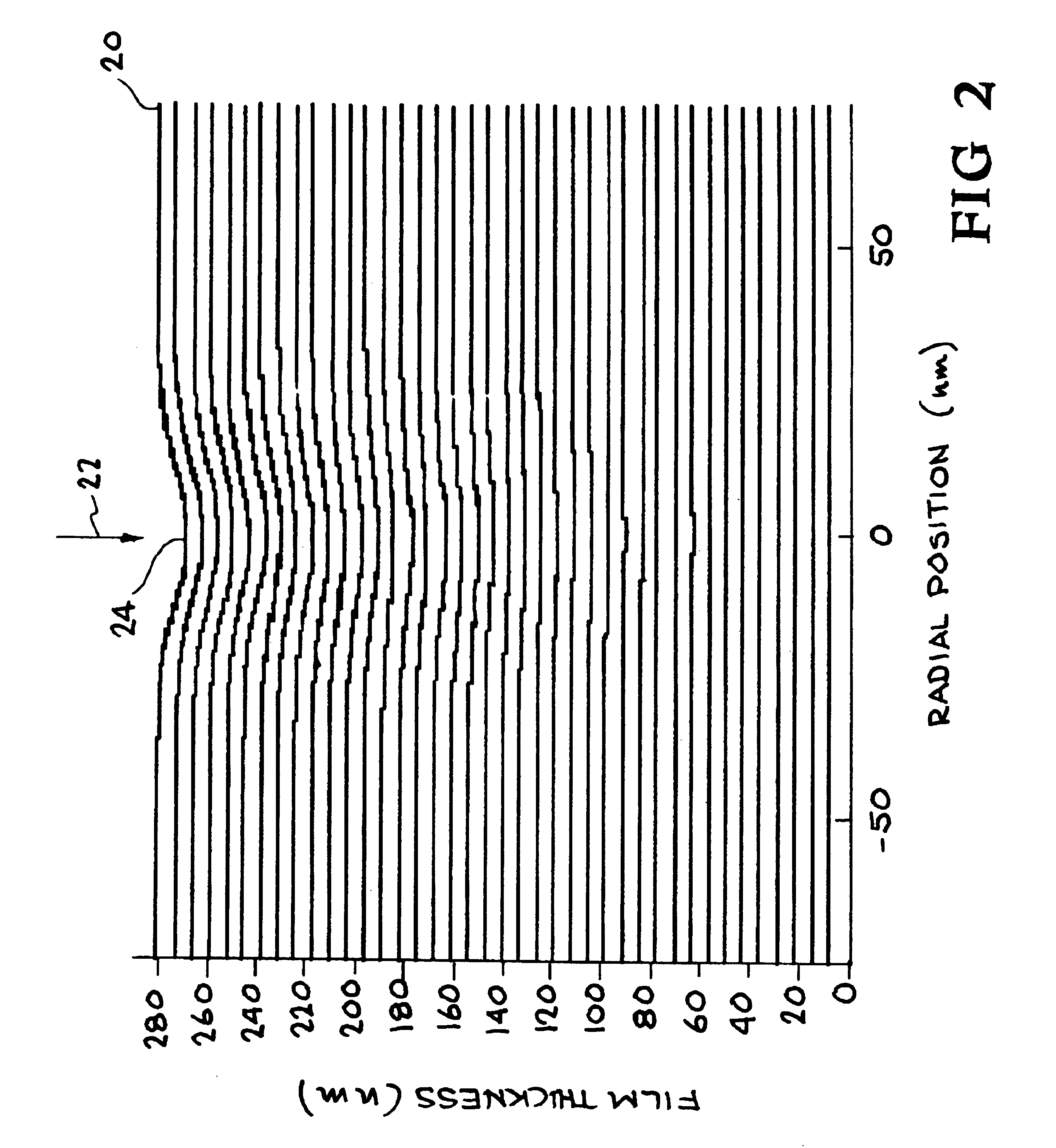

EUV lithography reticles fabricated without the use of a patterned absorber

InactiveUS7049033B2Significant commercial potentialLow costElectric discharge tubesNanoinformaticsElectronEnergy dose

Absorber material used in conventional EUVL reticles is eliminated by introducing a direct modulation in the complex-valued reflectance of the multilayer. A spatially localized energy source such as a focused electron or ion beam directly writes a reticle pattern onto the reflective multilayer coating. Interdiffusion is activated within the film by an energy source that causes the multilayer period to contract in the exposed regions. The contraction is accurately determined by the energy dose. A controllable variation in the phase and amplitude of the reflected field in the reticle plane is produced by the spatial modulation of the multilayer period. This method for patterning an EUVL reticle has the advantages (1) avoiding the process steps associated with depositing and patterning an absorber layer and (2) providing control of the phase and amplitude of the reflected field with high spatial resolution.

Owner:EUV

Packet network interface apparatus and method

ActiveUS8649398B2Elimination of rate adaptingSmall circuitTime-division multiplexMultiple digital computer combinationsTime domainNetwork interface device

A packet network interface apparatus includes a media access control (MAC) module for constructing a packet for transmission over a packet network and a physical coding sublayer (PCS) module for encoding the packet for transmission over a physical interface. An inter packet gap module located between the MAC module and the PCS module directly transfers data to the PCS module while maintaining a certain inter packet gap by deleting or inserting idle characters. The inter packet gap module has at least one memory module for temporary storage of packet data. The modules preferably operate in a common time domain.

Owner:XILINX INC

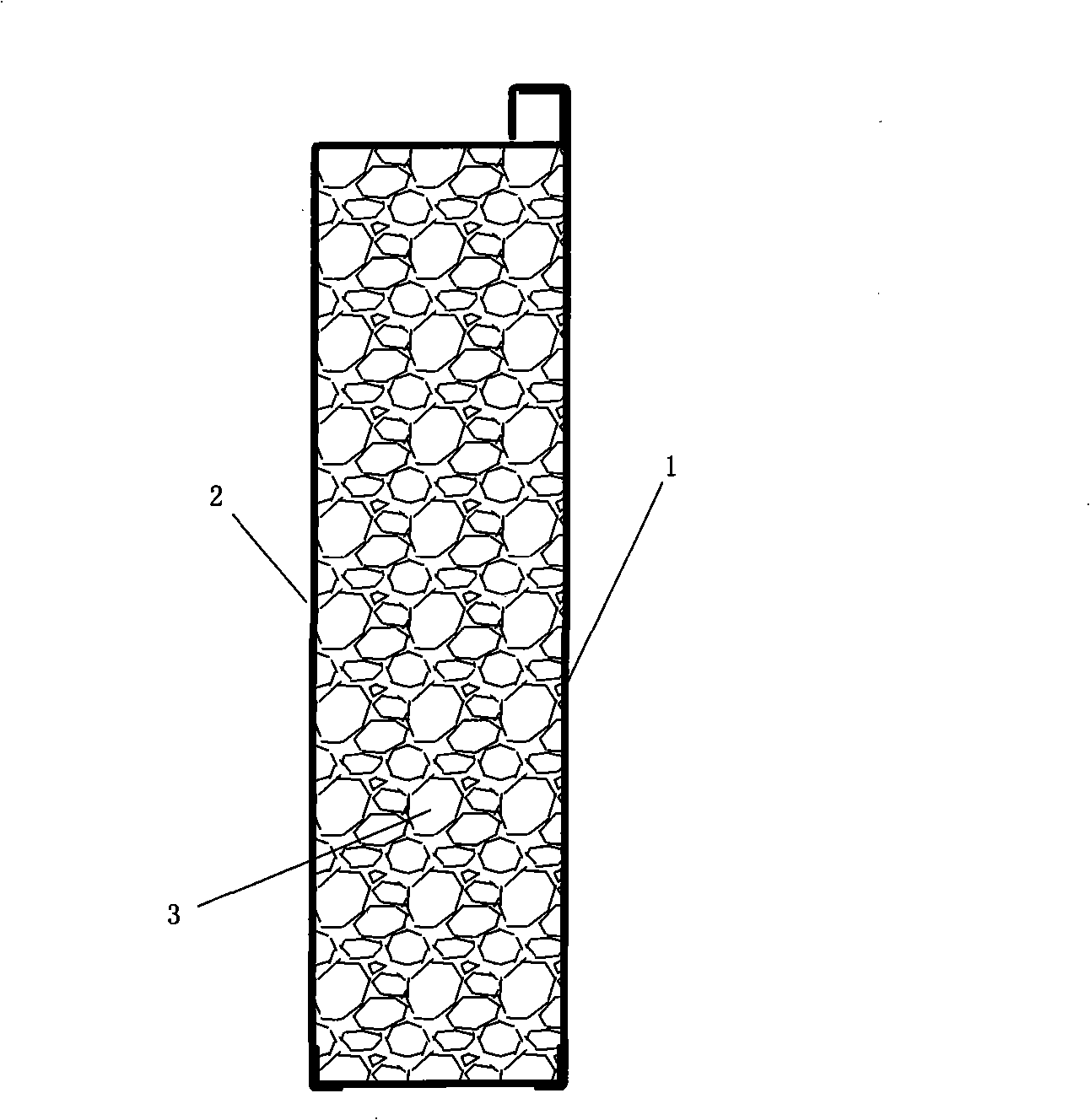

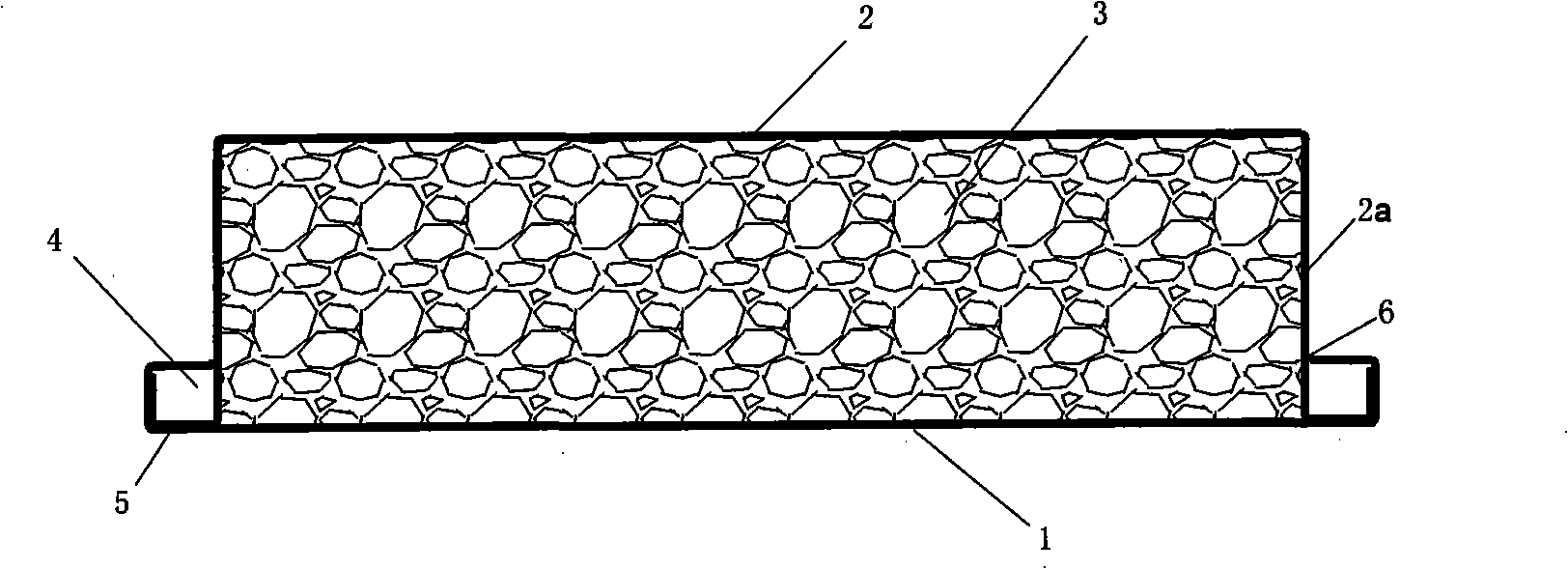

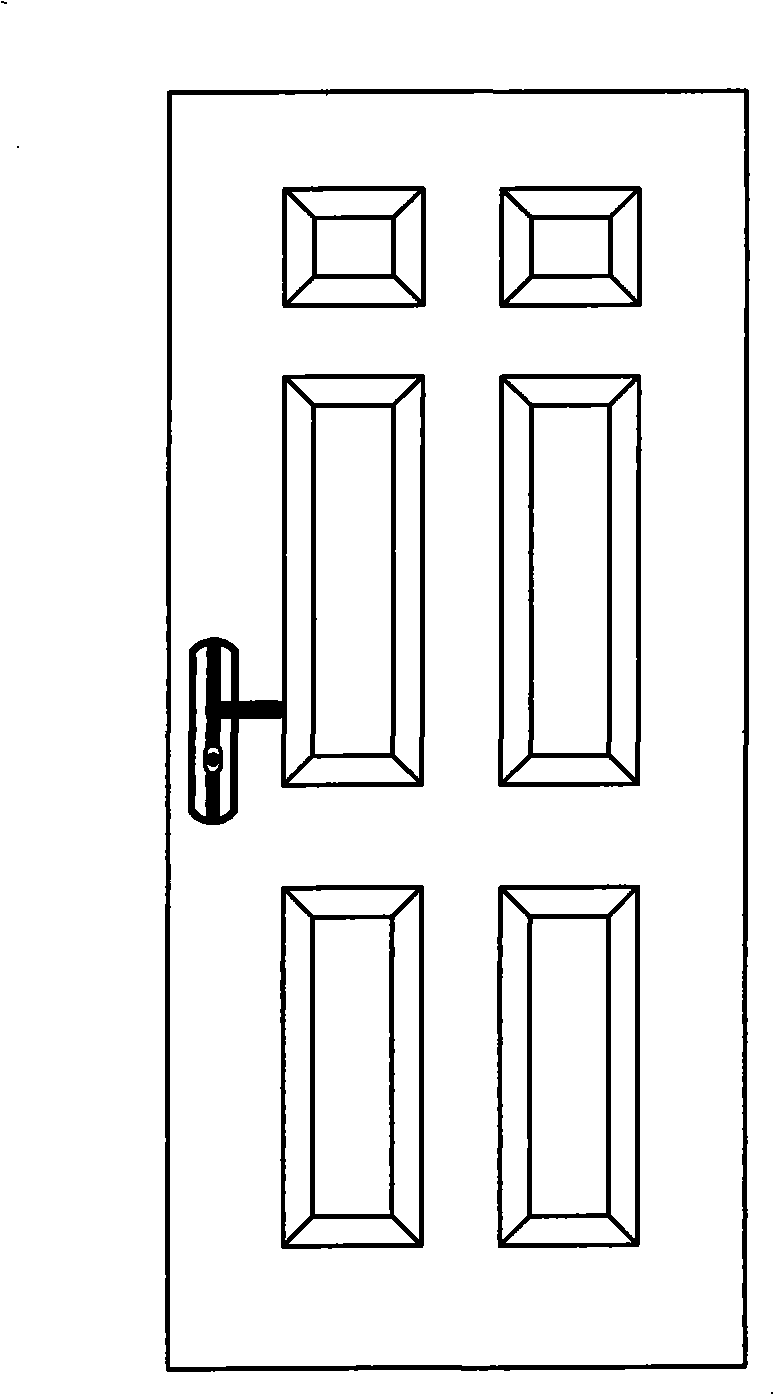

Steel security door section and hemming process

InactiveCN101315017AAesthetic impactDoes not affect aestheticsBurglary protectionSealing arrangementsEngineeringSpot welding

The invention relates to a steel security door leaf and a crimping process thereof. The steel security door leaf comprises a front door plate and a rear door plate, wherein a door core is filled in a cavity between the front door plate and the rear door plate. The steel security door leaf is characterized in that the side part of the front door plate is folded for 180 degrees inward, so as to cover the edge of the rear door plate, and form a three-layer sandwich-shaped fitted covered edge. The covered edge and the main body of the front door plate form a bending angle larger than and equal to 45 degrees. The crimping process comprises the following steps: (a), the side part of the front door plate is bent upwards, and the bending angle is larger than and equal to 90 degrees; (b), one open side of the cavity of the rear door plate is stuck to one side towards which the side part of the front door plate is bent, and the convex edge of the rear door plate is fitted with the front door plate; (c), the bent part of the front door plate is folded inwards, so as to cover the convex edge of the rear door plate, and the three-layer sandwich-shaped fitted covered edge is formed; and (d), the three-layer sandwich-shaped fitted covered edge is bent towards the inverse direction of the opening of the cavity of the rear door plate, and the overall bending angle is larger than and equal to 45 degrees. The steel security door leaf and crimping process have the advantages that the overall structural performance of the door leaf is good, and the strength is high; and the crimping process can avoid the spot welding process step.

Owner:陈少林

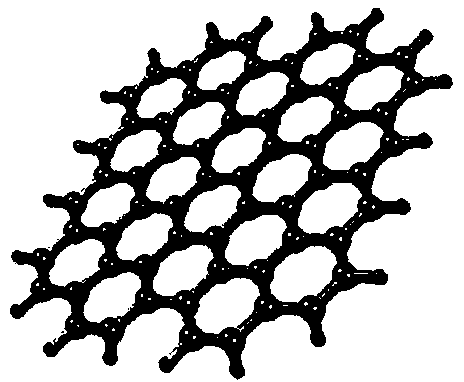

Method for manufacturing graphene nanowire device

InactiveCN103915348AAvoid process stepsSimple processNanoinformaticsSemiconductor/solid-state device manufacturingCvd grapheneIntegrated circuit manufacturing

The invention belongs to the technical field of carbon-based integrated circuit manufacturing, and particularly discloses a method for manufacturing a graphene nanowire device. The method includes the steps of etching a thin and long nanometer groove in a silicon dioxide substrate, and depositing a plurality of discontinuous small copper blocks in the groove through a mask plate, enabling the small copper blocks to serve as graphene coring sites, growing a layer of graphene nanowires in the groove through low-pressure chemical vapor deposition, growing high-K dielectric in the groove through atomic layer deposition to cover the graphene nanowires to form high-K gate dielectric of the device, and then manufacturing electrodes of the source, the drain and the gate of the device to form the graphene nanowire device. The method is simple, convenient to use and reliable, the ultra-long nanowires can be manufactured, the energy gap of the graphene nanowires is large, and the high-K gate dielectric can be formed on graphene through atomic layer deposition. The method can serve as a basic method for manufacturing the graphene nanowire device.

Owner:FUDAN UNIV

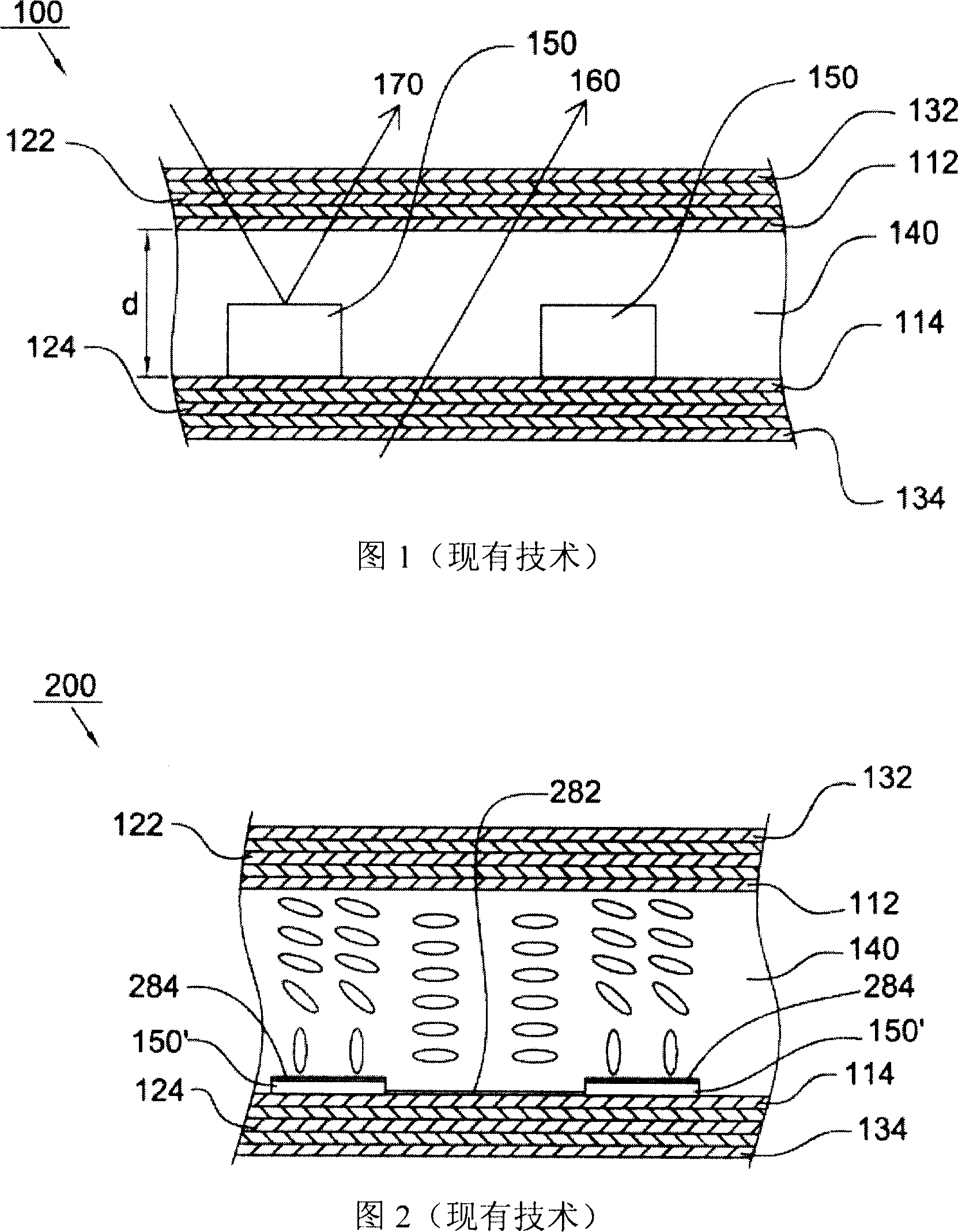

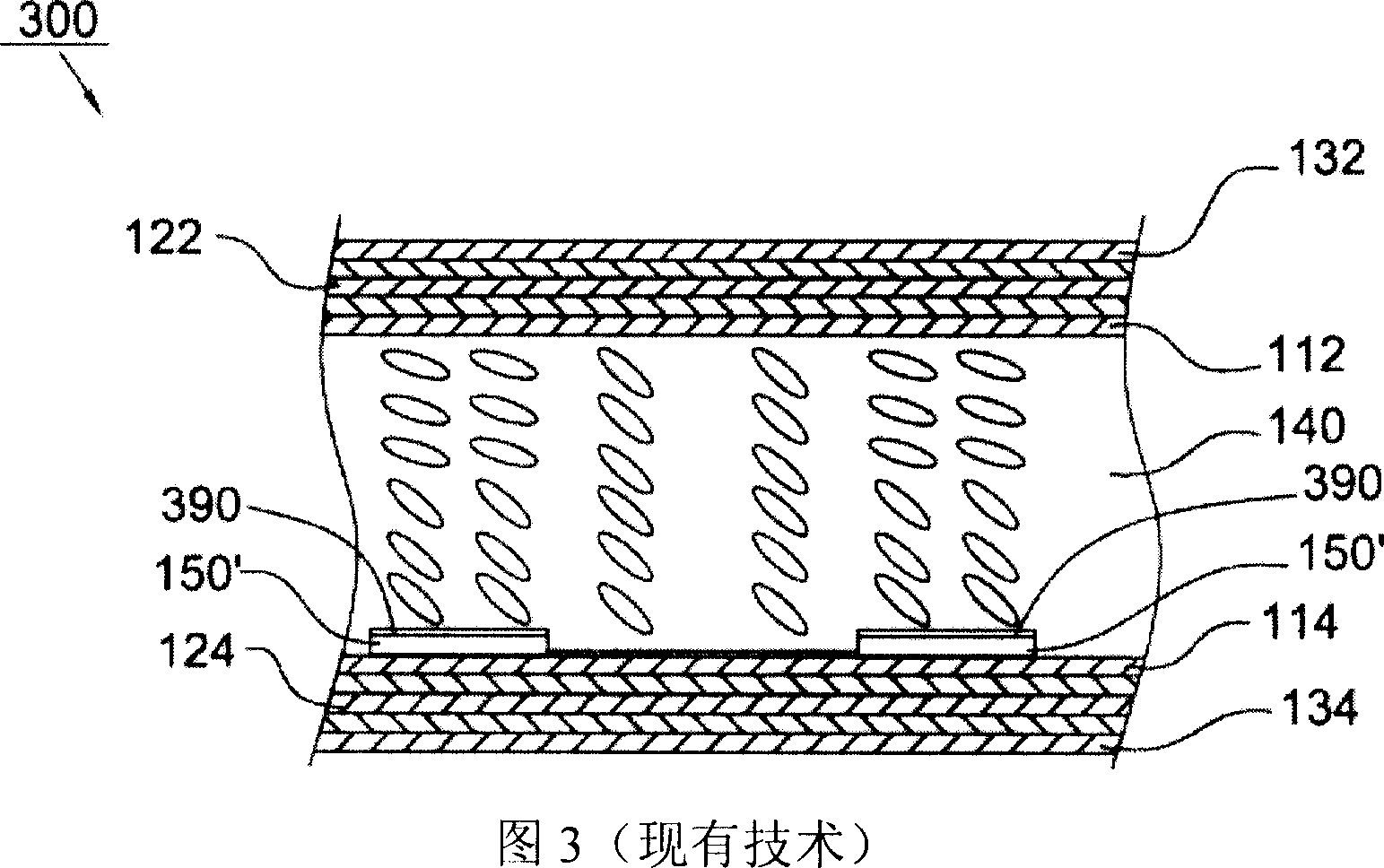

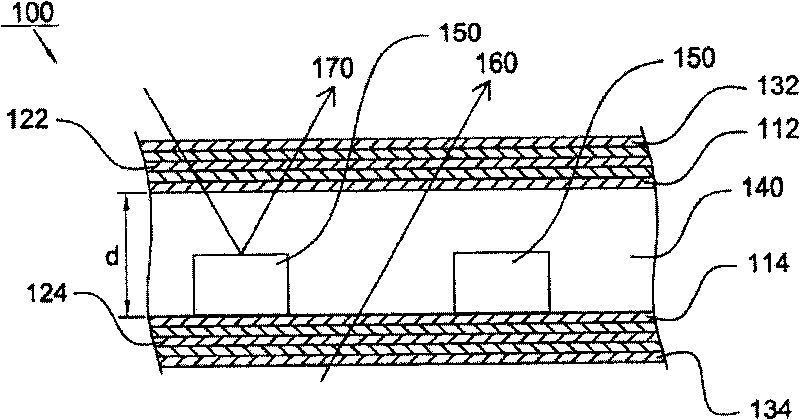

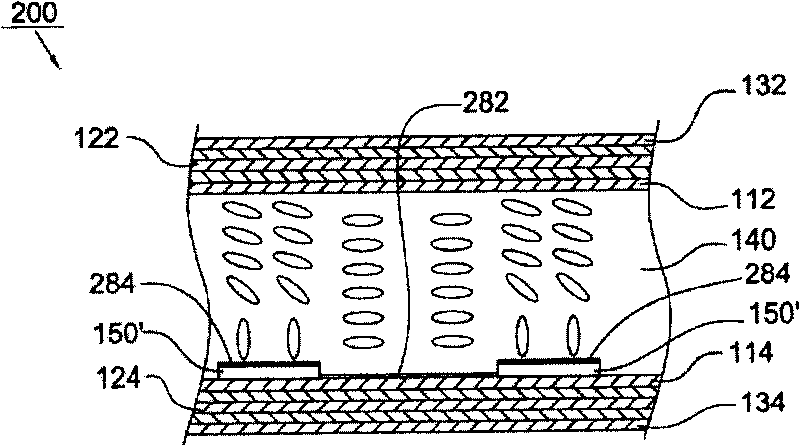

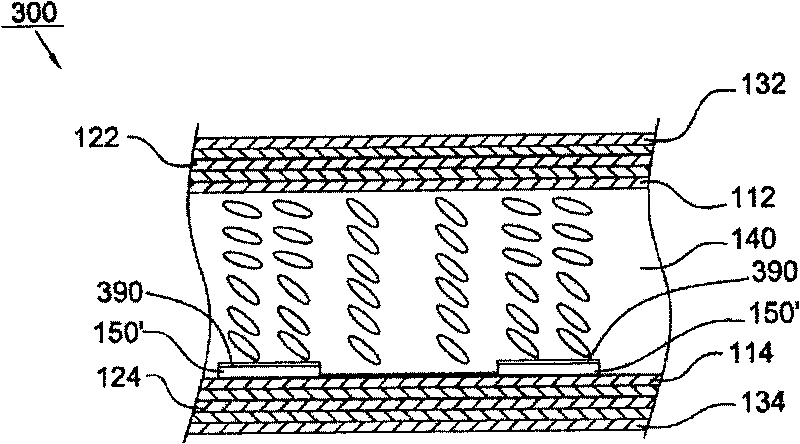

Semi-penetrating LCD

InactiveCN101109877AAvoid process stepsStatic indicating devicesNon-linear opticsElectrical resistance and conductanceLiquid-crystal display

The invention provides a semi-penetrating LCD. By setting a resistor between a penetrating electrode and a reflecting board, or by connecting in a floating and insulated way the reflecting board above the penetrating electrode and a grounding electrode, and adjusting the electric field size in the reflecting zone, the phase delay of the liquid crystal layer in the reflecting zone and the penetrating zone is adjusted, so that the thickness of the penetrating zone is actually same with that of the reflecting zone, this avoids the complicated making process for two layers of gap.

Owner:WINTEK CORP

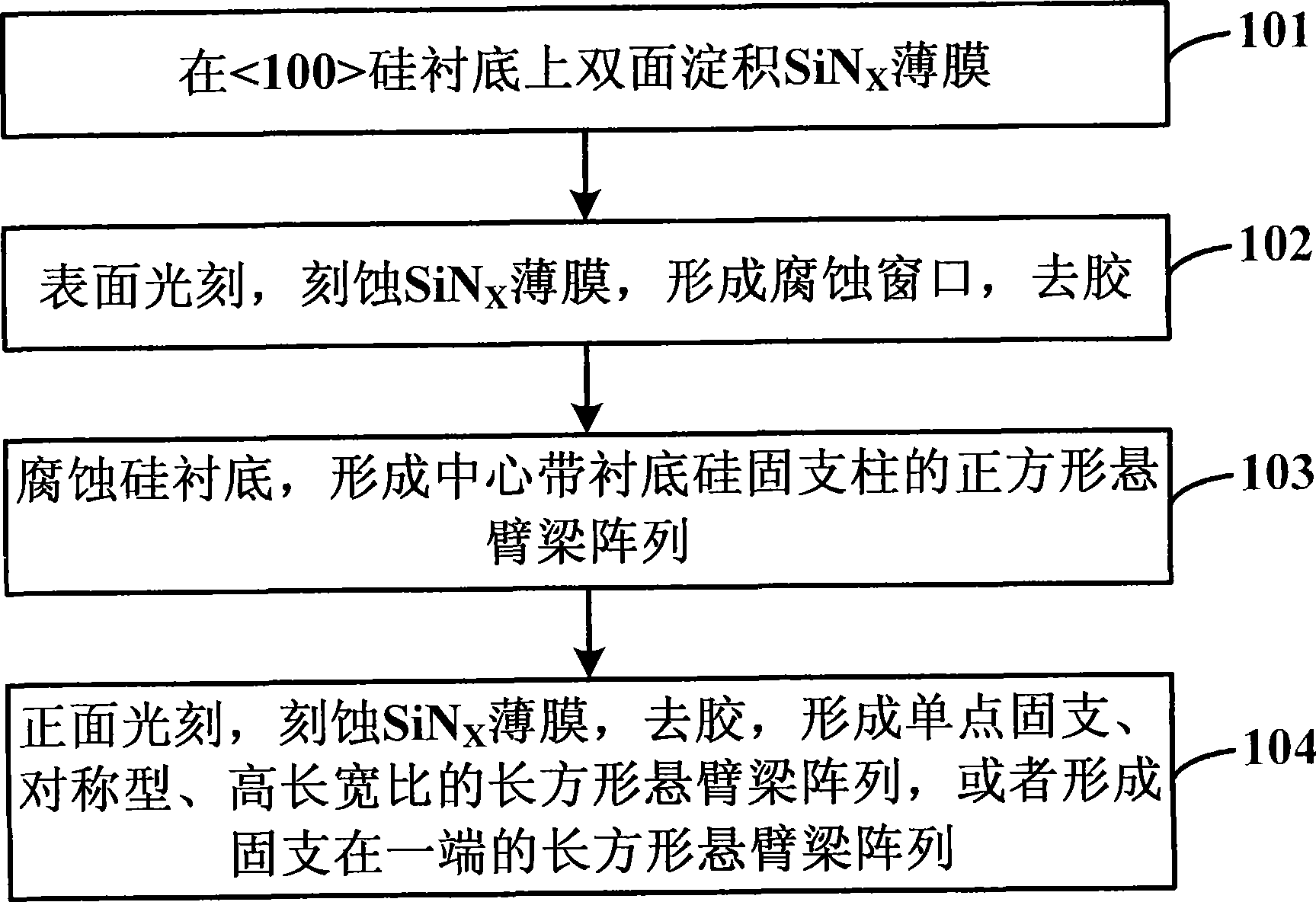

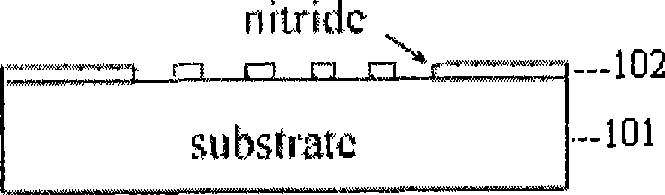

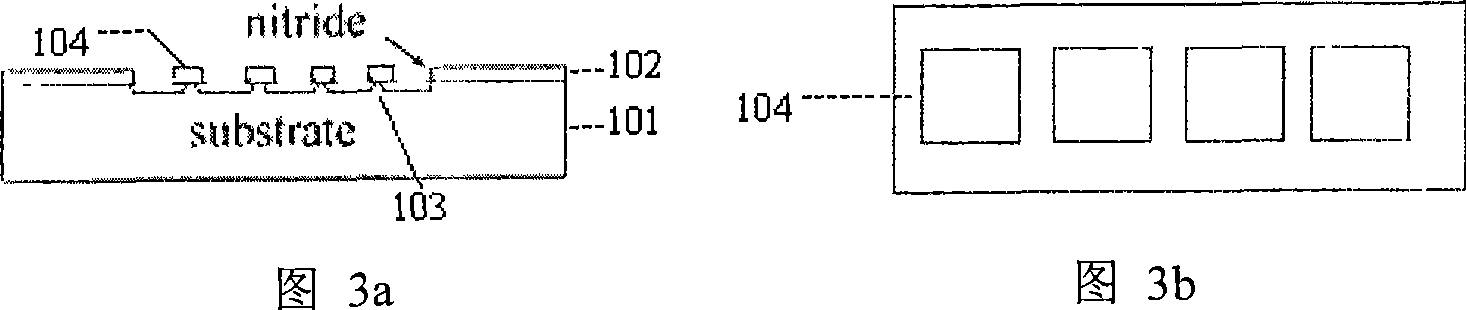

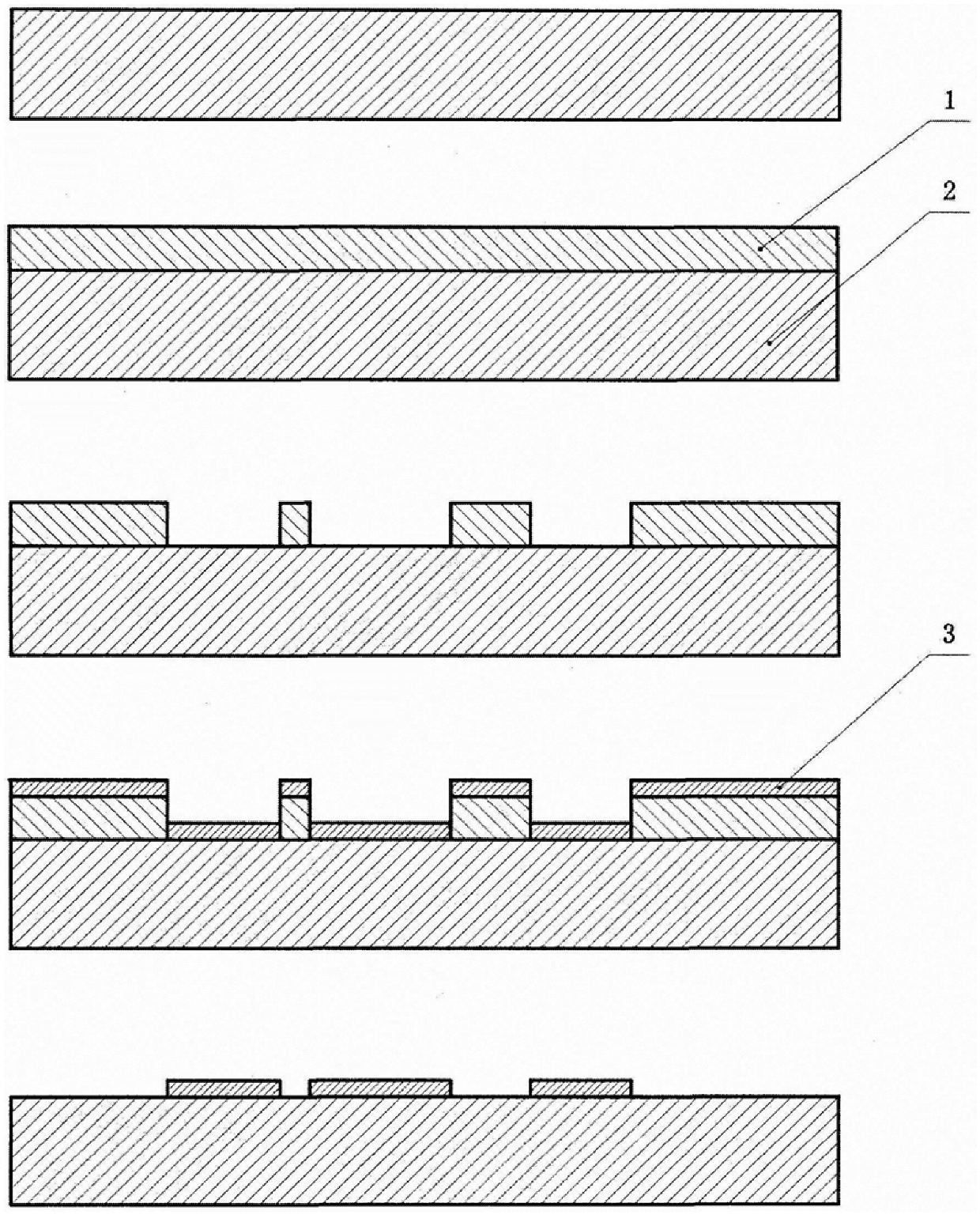

Method for manufacturing micro-mechanical cantilever beam array with substrate silicon as fixing column

InactiveCN101439842AProcess steps to avoid fillingAvoid process stepsDecorative surface effectsChemical vapor deposition coatingCantileverPhotoresist

The invention discloses a method for producing a micromechanical cantilever array taking substrate silicon as a clamping support, which comprises the following steps: a <100> silicon substrate is double-sidedly deposited with SiNx thin films; the surface lithography is performed, wherein the SiNx thin films are etched to form corrosion windows, and a photoresist is removed; the silicon substrate is corroded to form a square cantilever array with a substrate silicon clamping column at the center; and the frontal lithography is performed, wherein the SiNx thin films are etched, and the photoresist is removed to form a rectangular cantilever array with single-point clamped supporting, symmetry and high length-width ratio, or form a rectangular cantilever array clamped at one end. The utilization of the method simplifies a production process and can adapt to the requirement of mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

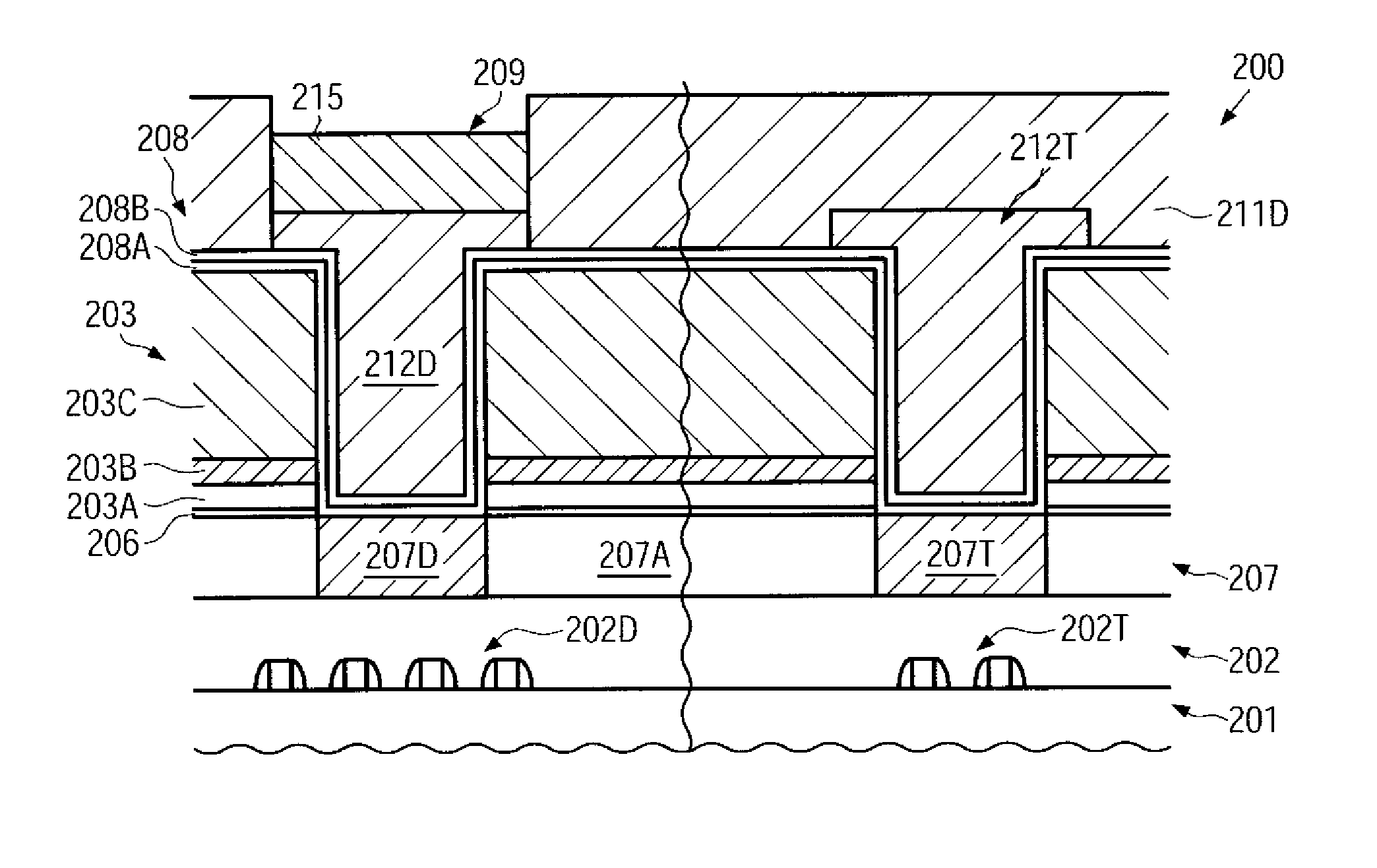

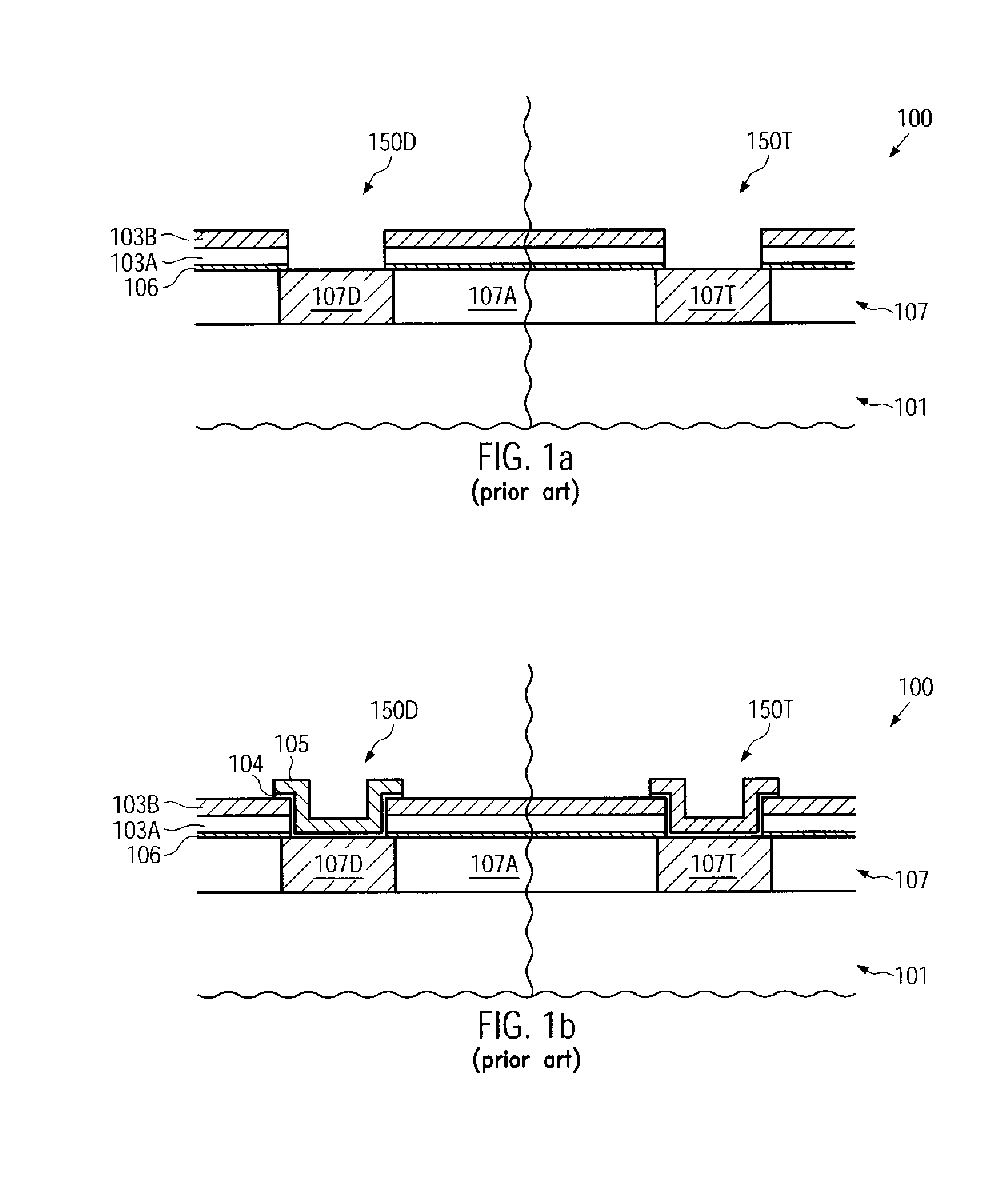

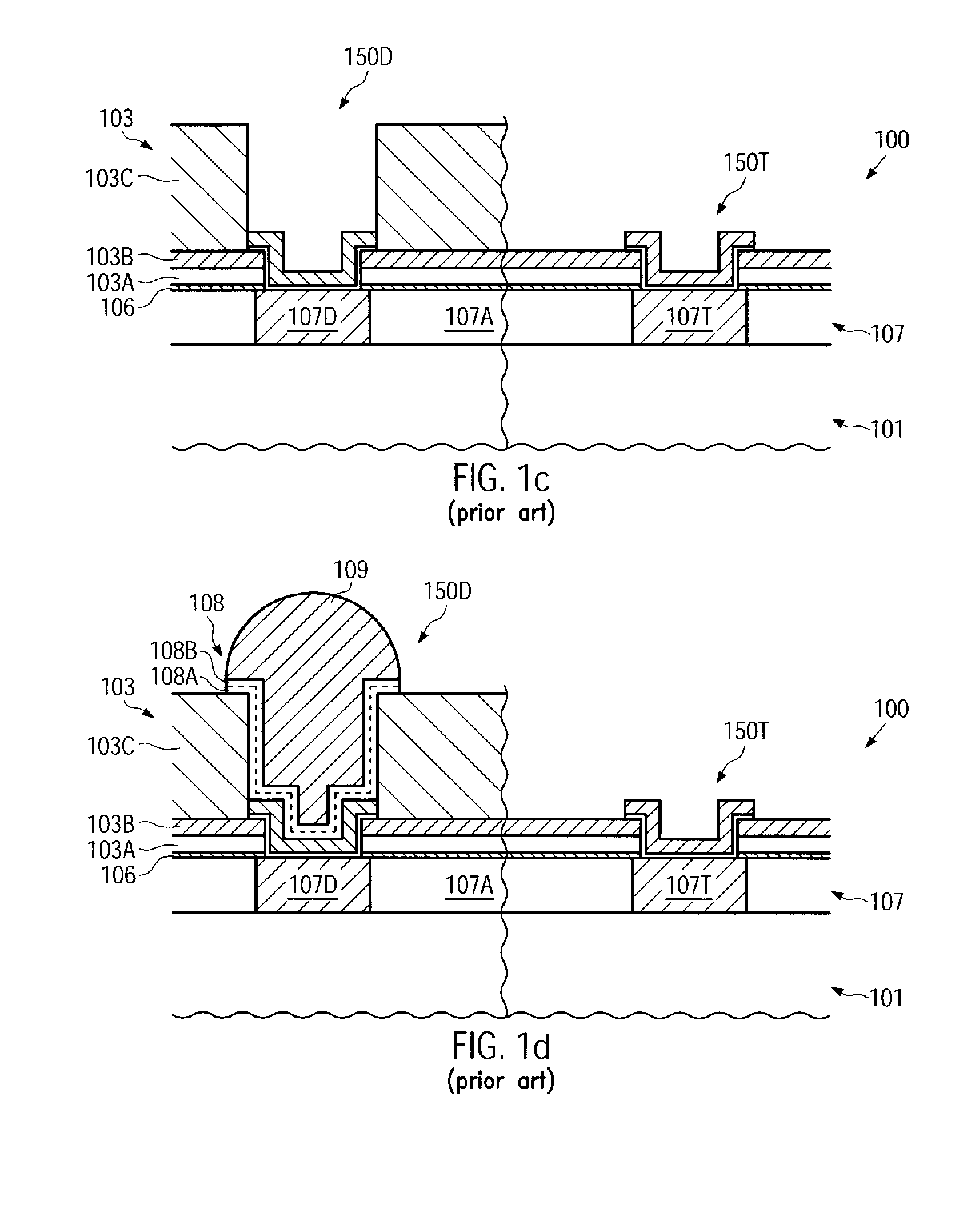

Semiconductor device including a die region designed for aluminum-free solder bump connection and a test structure designed for aluminum-free wire bonding

ActiveUS8283247B2Avoiding highly complex deposition and patterning processRelease resourcesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringContact element

In sophisticated semiconductor devices including copper-based metallization systems, a substantially aluminum-free bump structure in device regions and a substantially aluminum-free wire bond structure in test regions may be formed on the basis of a manufacturing process resulting in identical final dielectric layer stacks in these device areas. The number of process steps may be reduced by making a decision as to whether a substrate is to become a product substrate or test substrate for estimating the reliability of actual semiconductor devices. For example, nickel contact elements may be formed above copper-based contact areas wherein the nickel may provide a base for wire bonding or forming a bump material thereon.

Owner:ADVANCED MICRO DEVICES INC

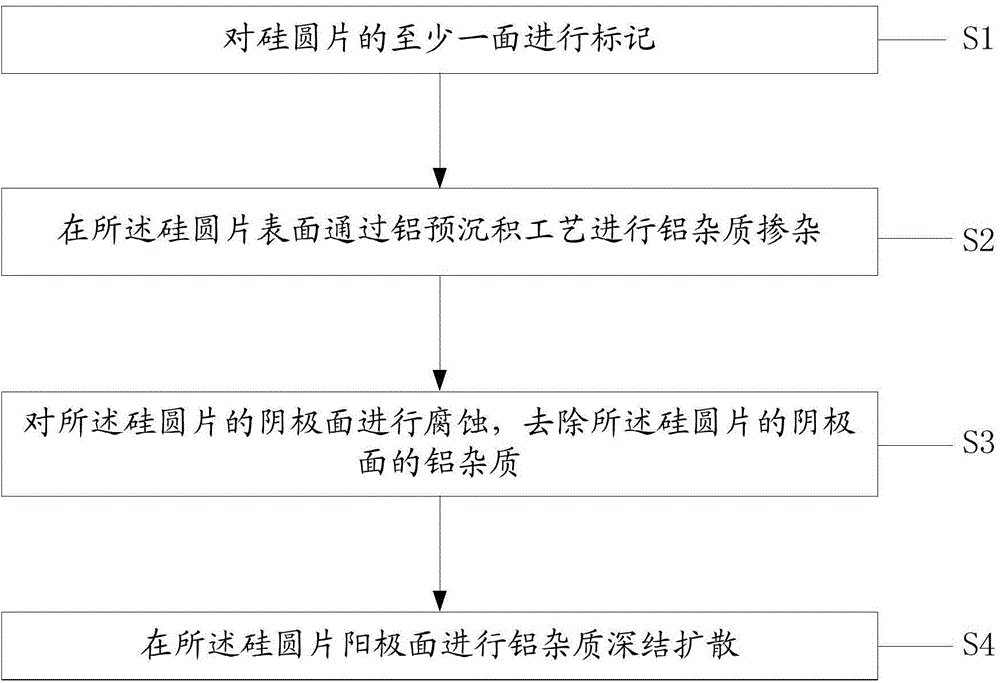

Manufacturing method of high-power rectification tube core

ActiveCN104576363AAvoid process stepsAvoid surface defects and microcracksSemiconductor/solid-state device manufacturingSemiconductor devicesAluminiumMicro cracks

The invention discloses a manufacturing method of a high-power rectification tube core. The method comprises the steps of marking at least one face of a silicon wafer; conducting aluminum impurity doping on the surface of the silicon wafer through the aluminum pre-deposition technology; corroding the cathode face of the silicon wafer, and removing aluminum impurities on the cathode face of the silicon wafer; conducting aluminum impurity deep-junction diffusion on the anode face of the silicon wafer. By means of the manufacturing method, surface defects and micro cracks of the silicon wafer can be prevented from being generated, and therefore the finished product rate and the long-term reliability of the high-power rectification tube core can be improved.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

A thin film patterning method on a flexible substrate

ActiveCN107529387BAvoid process stepsExtended film material rangeDecorative surface effectsPhotomechanical apparatusMicrofabricationPhotoresist

The invention discloses a film patterning method on a flexible substrate, which belongs to the field of microprocessing. This method directly attaches the entire dry film for photolithographic exposure, avoiding the problem of poor flatness and uniformity caused by spin-coating liquid photoresist on the flexible substrate that affects the exposure accuracy, and also avoids the curing of liquid photoresist, etc. Complicated process steps; using the lift-off method instead of the etching process, the film to be removed is not directly deposited on the flexible substrate but separated by a dry film layer, which avoids the injection of the film material into the softer flexible substrate layer, so the final removal This part of the film is easier and more thorough, and at the same time it is suitable for forming films of difficult-to-etch materials, expanding the range of film materials and eliminating problems such as side etching.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

System with sub-nyquist signal acquisition and transmission and associated methods

ActiveUS8538329B2Efficiently signaledReduce total powerElectric signal transmission systemsNear-field transmissionEngineeringAnalog signal

A sensing and recovery system includes a sensing unit and a recovery unit coupled together. The sensing unit includes a sensor to generate a bandlimited continuous time analog signal, and a modulator coupled to the sensor to generate a modulated analog signal based upon modulation of the bandlimited continuous time analog signal at a modulating rate at least equal to a Nyquist rate for the bandlimited continuous time analog signal. A compressive sensing circuit is coupled to the modulator to generate a compressed sensed signal based upon conversion of the modulated analog signal at a sampling rate less than the Nyquist rate. The recovery unit recovers the bandlimited continuous time analog signal from the compressed sensed signal.

Owner:HARRIS CORP

Low-cost production method of low-carbon glassed steel

ActiveCN110317919ANitrogen controlNitrogen easyManufacturing convertersProcess efficiency improvementTemperature controlMetal

The invention discloses a low-cost production method of low-carbon glassed steel, and mainly solves the technical problems that in the prior art, low-carbon glassed steel has to adopt an RH furnace vacuum refining process, and is high in production cost. The technical scheme adopted by the invention is that the low-cost production method comprises the following steps: smelting by a top-bottom combined blowing converter, wherein the low-carbon glassed steel comprises the following main metal raw materials in percentage by mass: 75%-100% of molten iron and the balance of steel scrap; controllingthe converter smelting final point, and detecting w[C] in molten iron and the temperature of the molten iron at the converter blowing final point; immediately tapping after completing the converter blowing; and transporting molten iron in a steel ladle in an LF furnace to perform molten iron temperature control and molten iron component control. The low-carbon glassed steel produced by the low-cost production method is low in cost, and compared with an existing RH furnace vacuum refining process, the low-carbon glassed steel, produced by the low-cost production method, each ton is lower than20 yuan.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

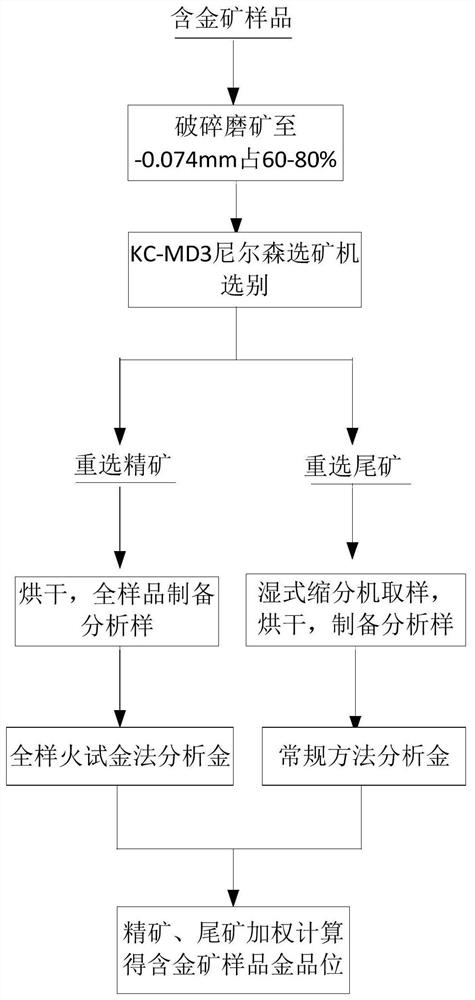

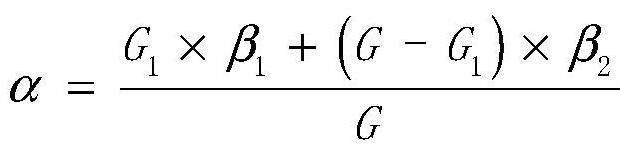

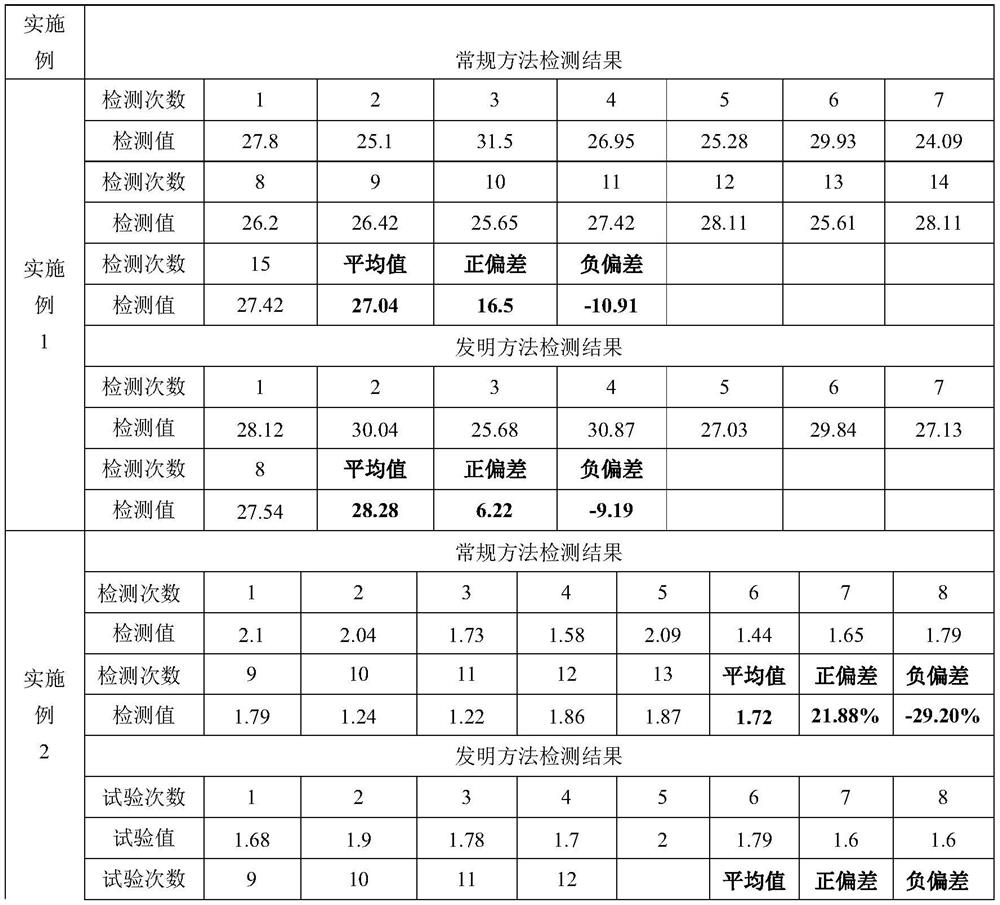

Analysis method for gold content of gold-containing ore sample

PendingCN113552311AExpand the sampling rangeAvoid process stepsMaterial analysisGold contentGold ore

The invention discloses an analysis method for the gold content of a gold-bearing ore sample, which comprises the following steps of: crushing and weighing the gold-bearing ore sample to be detected, sorting out reselected concentrate and reselected tailings through reselection equipment, analyzing the gold content of the reselected concentrate and the reselected tailings through a gold content detection method respectively, and determining the gold content of the gold-bearing ore sample after the results of the reselected concentrate and the reselected tailings are processed. The gold content of the reselected concentrate is detected by the fire assaying method according to the weight suitable for fire assaying method detection. According to the invention, a division process step is avoided, and the sampling range of the gold-containing ore sample to be detected is expanded, so that the detection result is accurate and real. Since the gold ore is different from other ores, the gold content is relatively low and the gold is scattered in the ores, a representative detection result is difficult to obtain if an existing detection method is adopted. The positive deviation and the negative deviation of the detection result of the conventional method represented by the embodiment of the invention are respectively 16-38% and 9-18%, and compared with the existing detection method, the method disclosed by the invention can reduce 75% of data fluctuation to the maximum extent.

Owner:江西省地质调查研究院

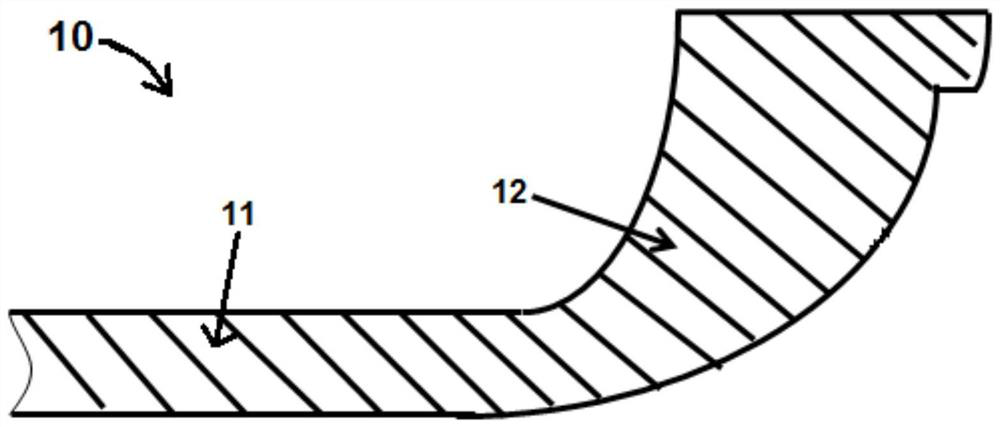

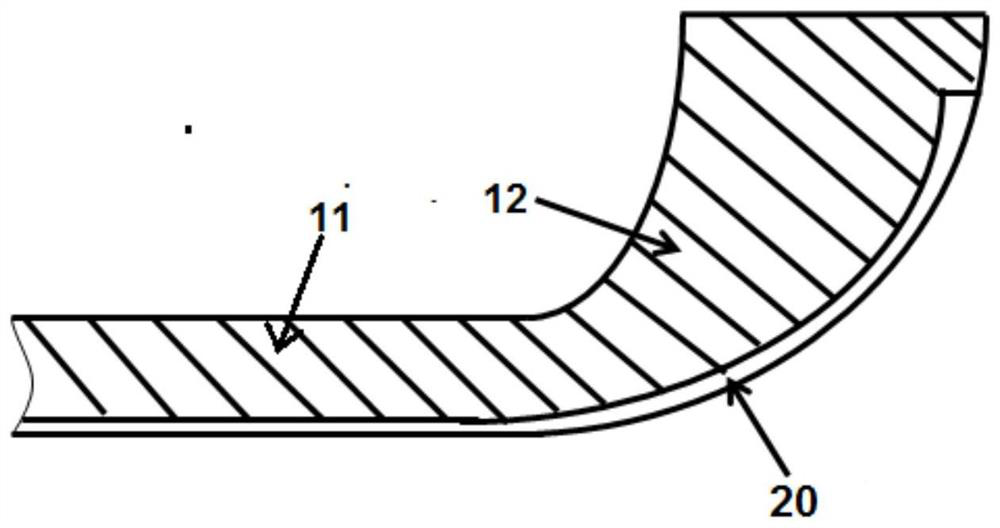

Composite plate and preparation method thereof, shell assembly and electronic equipment

PendingCN112123884AReduce manufacturing costHigh strengthSynthetic resin layered productsCasings/cabinets/drawers detailsTransmittanceComposite plate

The invention provides a composite plate and a preparation method thereof, a shell assembly and electronic equipment. The composite plate comprises a plastic base material, wherein the light transmittance of the plastic base material is greater than or equal to 90%; and ultrathin glass which is arranged on one surface of the plastic base material. Therefore, by arranging the ultrathin glass on onesurface of the plastic base material, the texture of the glass can be realized on the appearance surface (the surface, far away from the plastic base material, of the ultrathin glass) of the composite plate, so that the composite plate can be used for replacing the glass plate, the process step of hot bending forming can be avoided, the manufacturing cost can be reduced, and the process time canbe shortened.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Isoprene modified dicyclopentadiene petroleum resin, and preparation method thereof

The invention discloses an isoprene modified dicyclopentadiene petroleum resin, and a preparation method thereof. The isoprene modified dicyclopentadiene petroleum resin comprises a cyclopentadiene monomer, isoprene, an inert solvent, an antioxidant, an initiator and a terminator. The preparation method comprises the following steps: initiating the polymerization of the isoprene to prepare a 3,4-isoprene / 1,4-isoprene block oligomer, modifying cyclopentadiene polymerized petroleum resin, and purifying the modified petroleum resin to obtain the isoprene modified dicyclopentadiene petroleum resin. The modified petroleum resin has the advantages of good caking property, high softening point, greatly increased compatibility with elastomer material, low chroma, enlargement of the application range of petroleum resin, and good application values. The preparation method is simple and easy, and is suitable for being promoted and applied.

Owner:安徽同心新材料科技有限公司

Fiber-Reinforced Plastic Parts Made With Untreated Embossed Surfacing Veils With No Whitening Agents

InactiveUS20110236638A1Cost reductionAvoid process stepsLayered productsDecorative surface effectsWhitening AgentsEngineering

Untreated, embossed surfacing veils with no whitening additives can be used in a fiber-reinforced process to make parts that are more vibrant in color. The lack of whitening agents minimizes the color pollution and provides a part that is richer in color with a smooth, glossy surface. Fabrics with unbonded areas used as surfacing veils allow the veils to be more flexible, improving the performance in the process. High air permeability above 685 cubic feet per minute per square foot is also beneficial in allowing resin to freely flow through the surfacing veil.

Owner:CEREX ADVANCED FABRICS

A low-cost production method of low-carbon enamelled steel

ActiveCN110317919BNitrogen controlNitrogen easyManufacturing convertersProcess efficiency improvementMolten steelLadle

The invention discloses a low-cost production method of low-carbon enamelled steel, which mainly solves the technical problems in the prior art that the low-carbon enameled steel must adopt the RH furnace vacuum refining process and the production cost is high. The technical solution of the present invention is: a low-cost production method of low-carbon enamelled steel, comprising: using a top-bottom combined blowing converter for smelting, the mass percentage of the main metal raw material is 75% to 100% of molten iron, and the balance is scrap steel; The control of the converter smelting end point is to detect the w[C] and temperature of the molten steel at the converter blowing end point; the steel is tapped immediately after the converter blowing end; the molten steel in the ladle is transported to the LF furnace for the regulation of the molten steel temperature and the composition of the molten steel. The low-carbon enamel steel produced by the method of the invention has low cost, and compared with the existing RH furnace vacuum refining process, the production cost is 20 yuan / ton steel lower.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

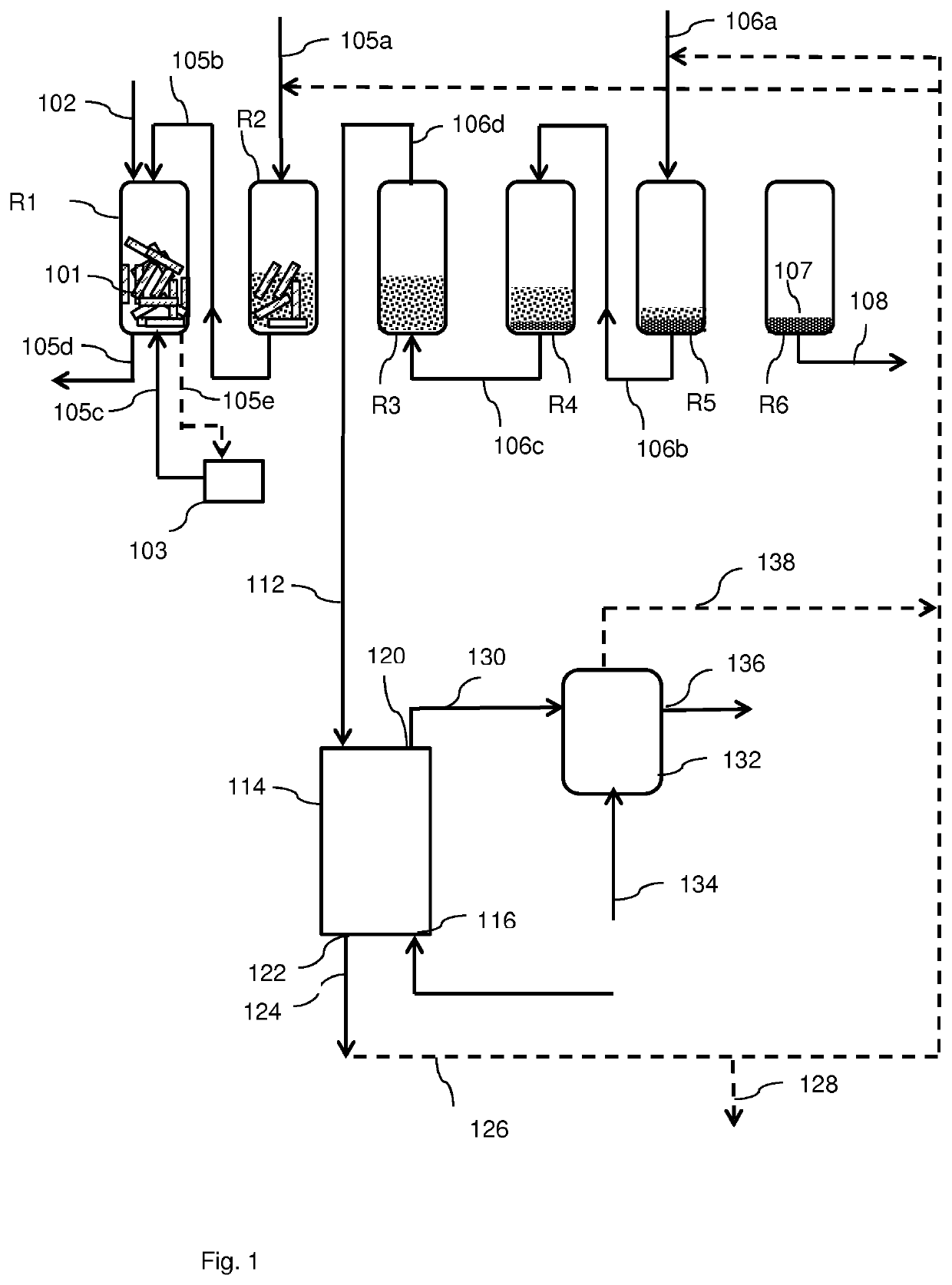

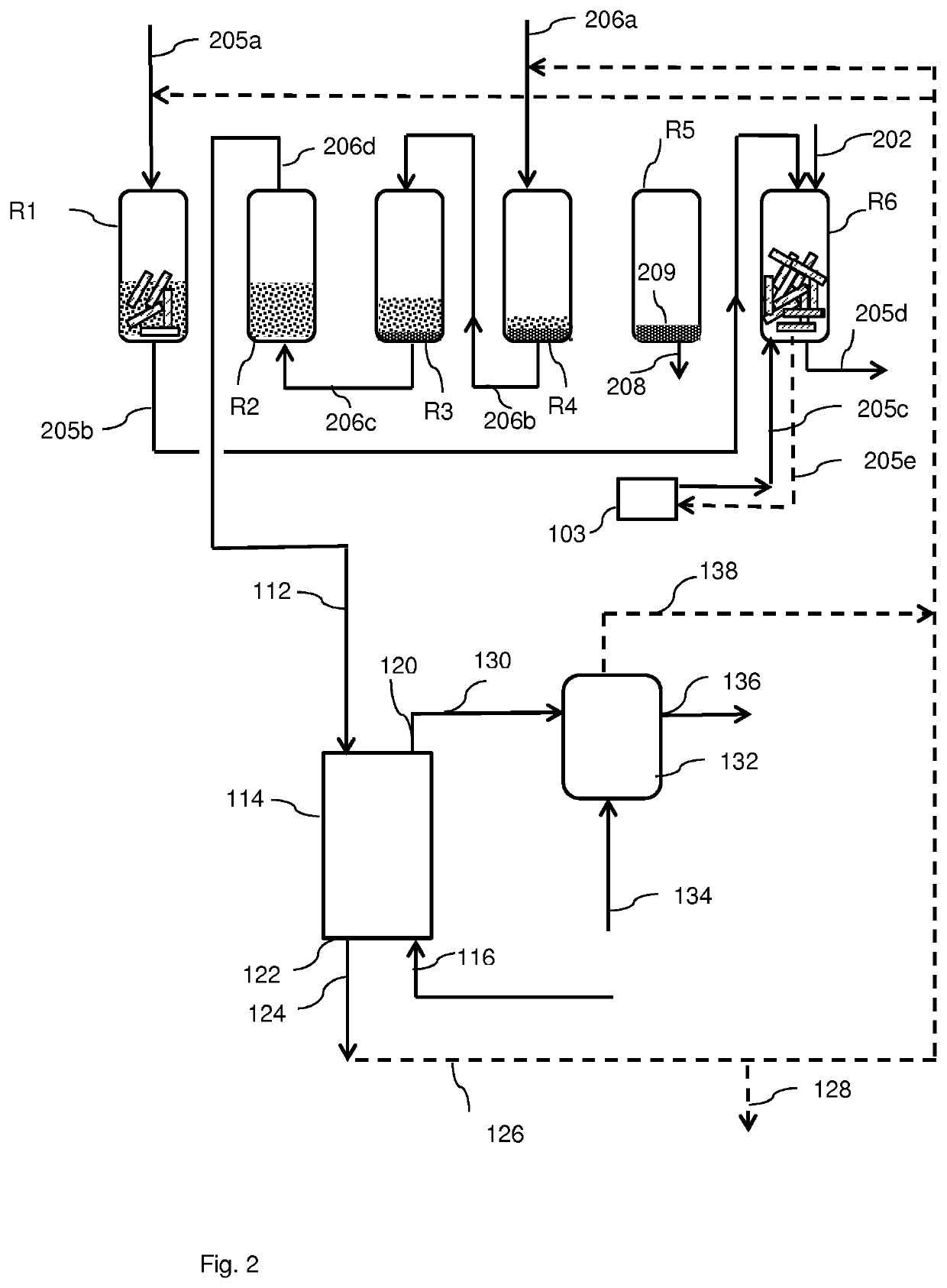

Process for the conversion of a solid lignocellulosic material

ActiveUS20210032217A1Improve scalabilityAdvantageously flexibleOrganic compounds purification/separation/stabilisationBiofuelsHydrolysateFurfural

A process includes the following steps: a) converting a solid material containing hemicellulose, cellulose and lignin, by: (i) hydrolyzing at least part of the hemicellulose of the solid material with a first aqueous hydrochloric acid solution, yielding a remaining solid material and a hydrochloric acid- containing, aqueous, first hydrolysate product solution; (ii) hydrolyzing at least part of the cellulose of the remaining solid material with a second aqueous hydrochloric acid solution, yielding a residue and a hydrochloric acid-containing, aqueous, second hydrolysate product solution; (b) forwarding to step (c) a, hydrochloric acid-containing, aqueous intermediate product solution comprising: a part of or the whole of the hydrochloric acid-containing, aqueous first and / or second hydrolysate product solution of step (a); and (c) heating at least part of the hydrochloric acid-containing, aqueous intermediate product solution to yield a product solution containing 5-(chloromethyl)furfural, and extracting the 5-(chloromethyl)furfural from the product solution into an extraction solvent.

Owner:FURANIX TECH BV

Semi-penetrating LCD

InactiveCN101109877BAvoid process stepsStatic indicating devicesNon-linear opticsElectrical resistance and conductanceLiquid-crystal display

The invention provides a semi-penetrating LCD. By setting a resistor between a penetrating electrode and a reflecting board, or by connecting in a floating and insulated way the reflecting board abovethe penetrating electrode and a grounding electrode, and adjusting the electric field size in the reflecting zone, the phase delay of the liquid crystal layer in the reflecting zone and the penetrating zone is adjusted, so that the thickness of the penetrating zone is actually same with that of the reflecting zone, this avoids the complicated making process for two layers of gap.

Owner:WINTEK CORP

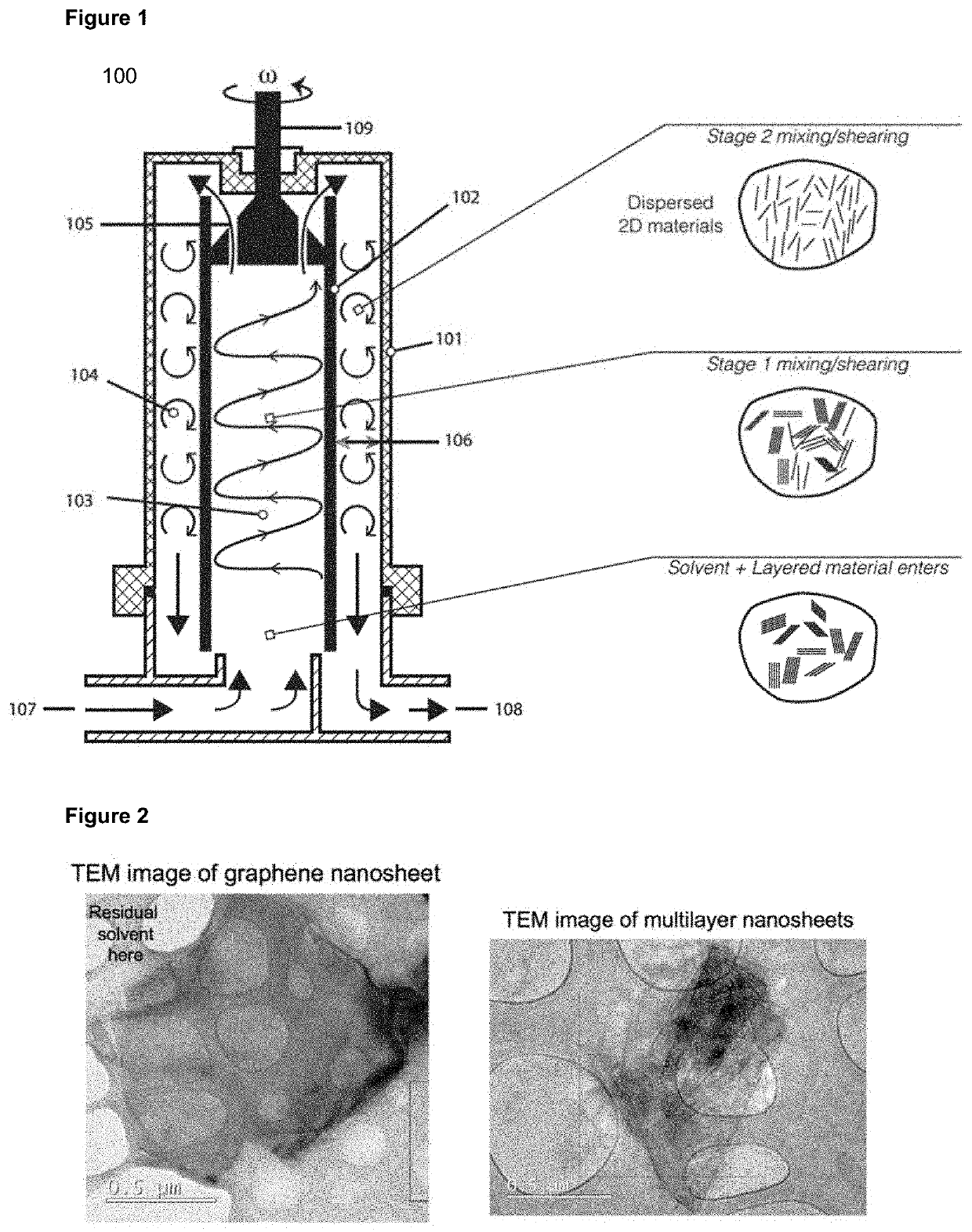

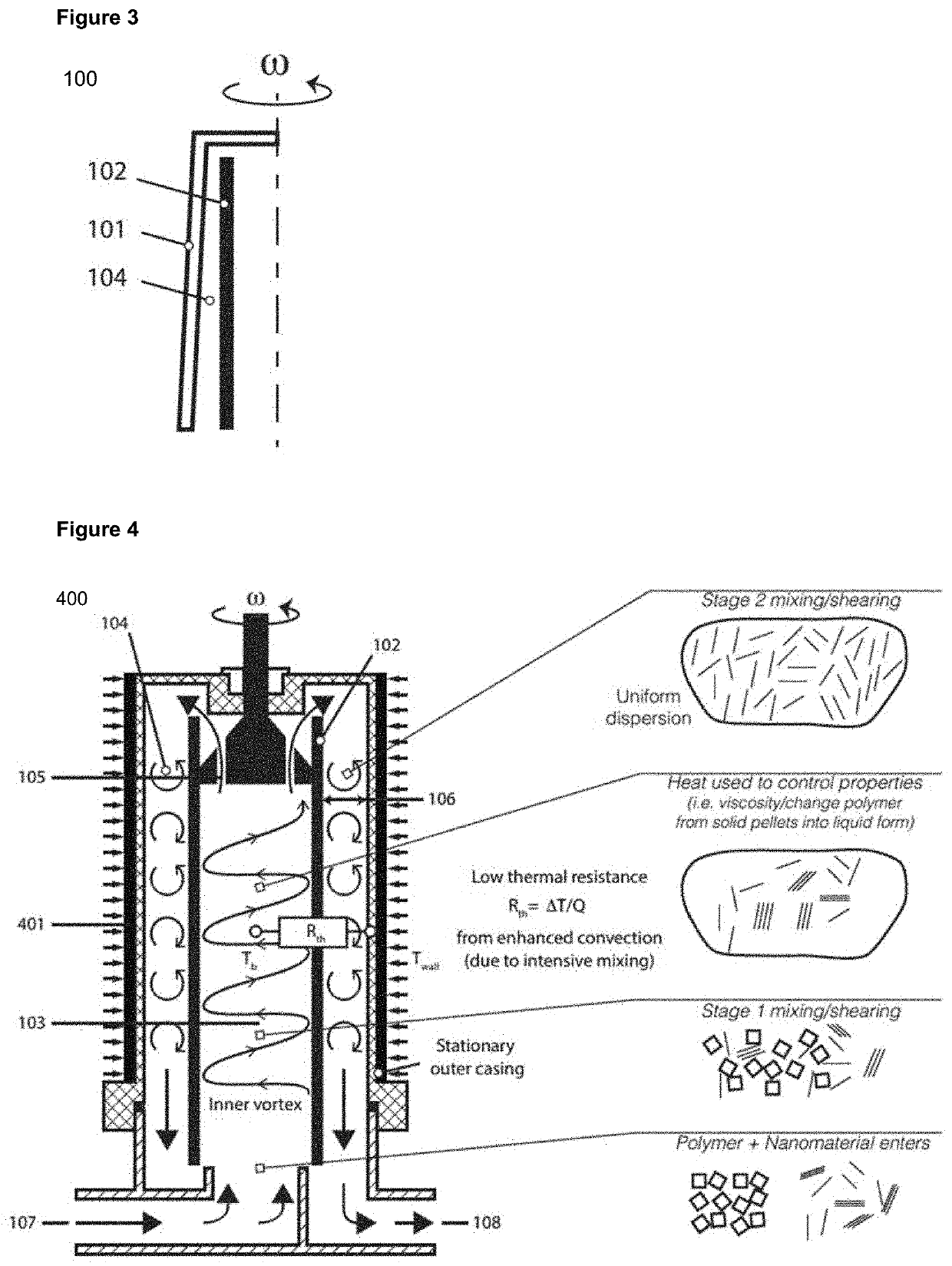

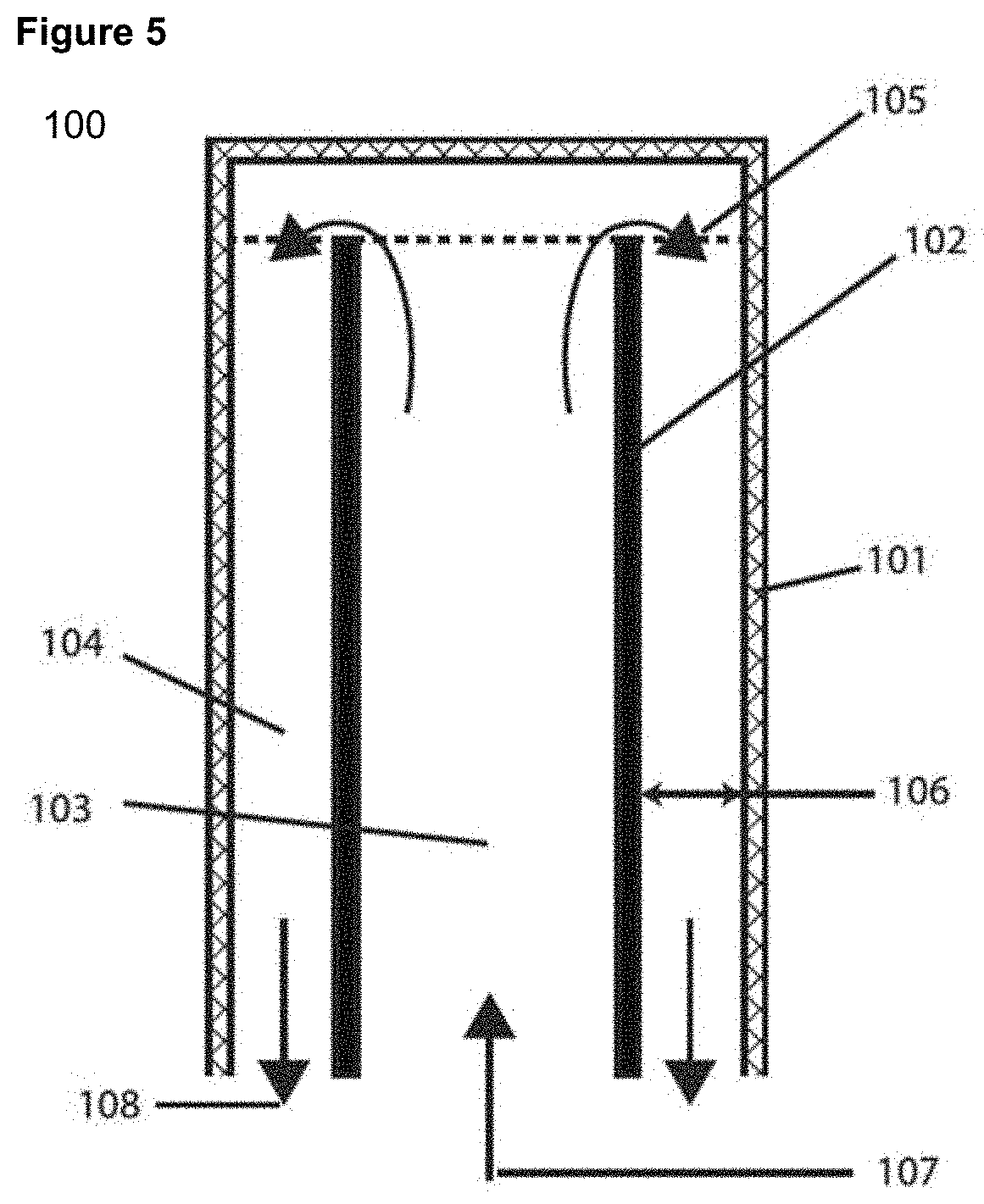

Fluidic exfoliation

PendingUS20200255294A1Settling time is shortAvoid process stepsNitrogen compoundsGraphenePhysicsMechanical engineering

The invention provides an apparatus for fluidic exfoliation of a layered material comprising: a housing of circular cross-section defined by a housing wall; a hollow rotor of circular cross-section having a first end and a second end and a wall positioned therebetween arranged concentrically within the housing, wherein the wall of the hollow rotor defines an inner chamber and the space in between the wall of the hollow rotor and the housing wall defines an outer chamber, and wherein a fluid flow path is provided between the inner chamber and the outer chamber; a fluid inlet in fluid communication with the inner chamber or the outer chamber; and a fluid outlet in fluid communication with the other of the inner chamber or the outer chamber; wherein the outer chamber has a width such that on passage of a fluid comprising the layered material from the inlet to the outlet through the outer chamber, a shear rate sufficient to exfoliate the layered material may be applied to the fluid comprising the layered material in the outer chamber by rotation of the hollow rotor.

Owner:IMPERIAL INNOVATIONS LTD

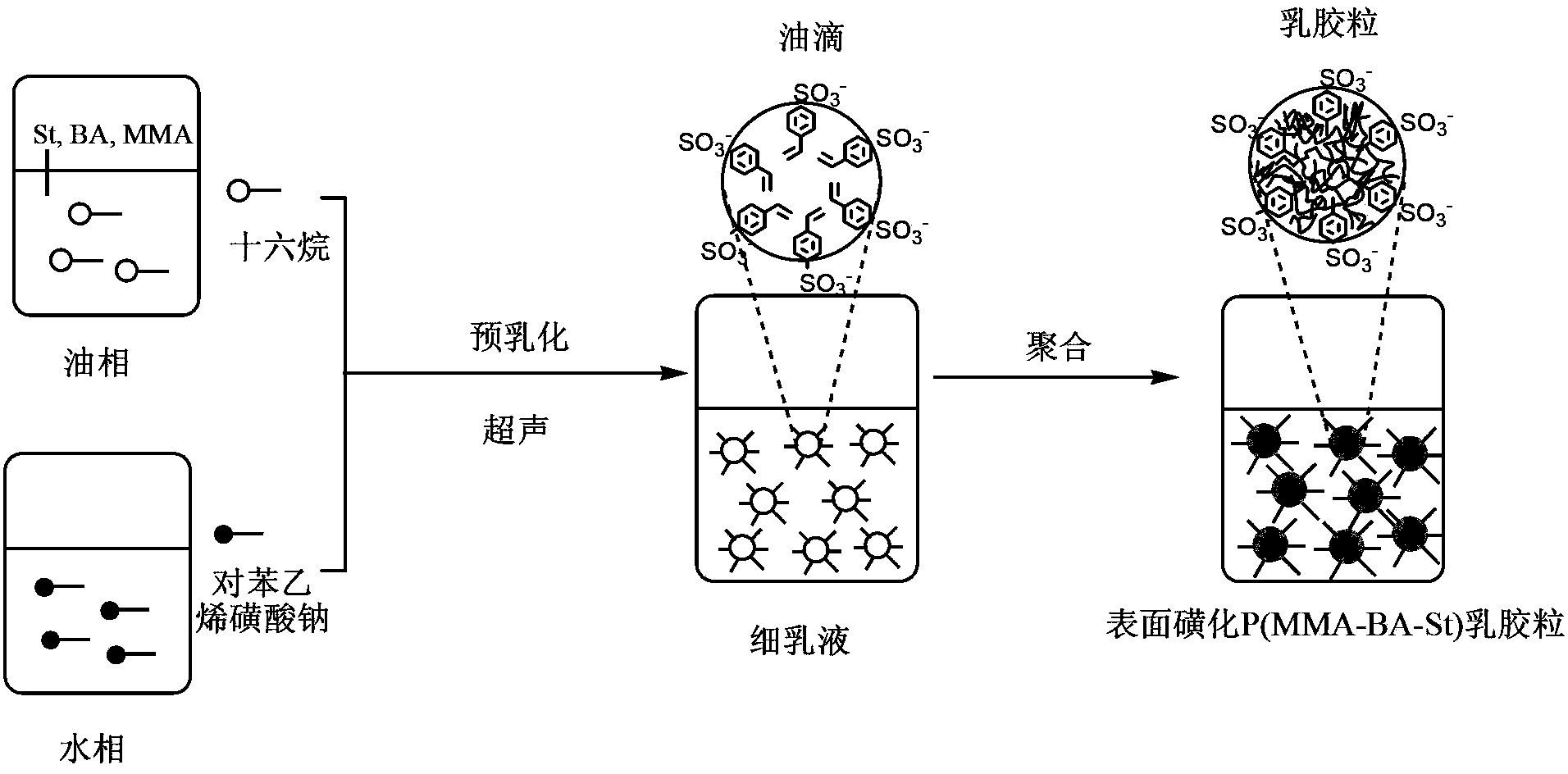

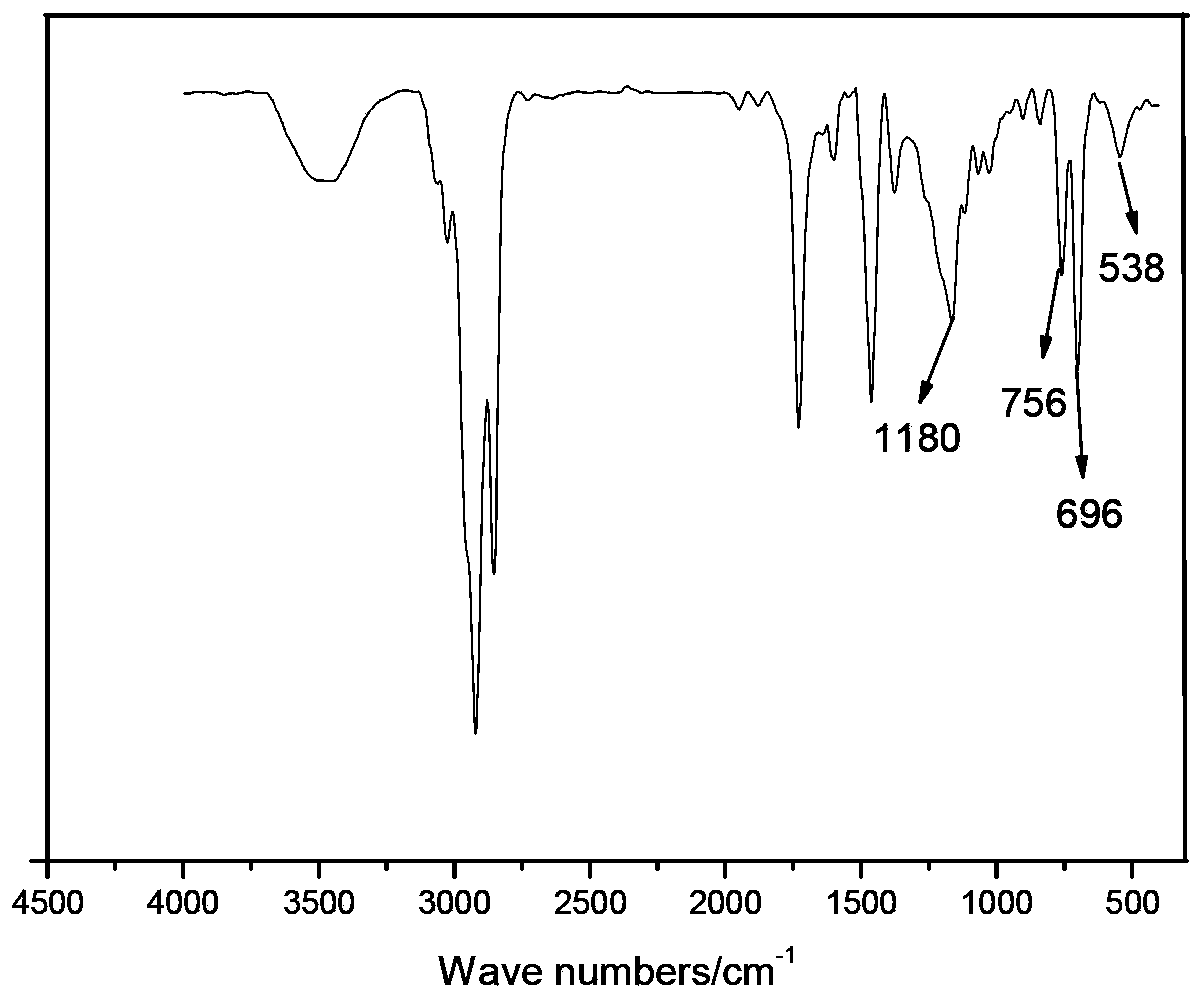

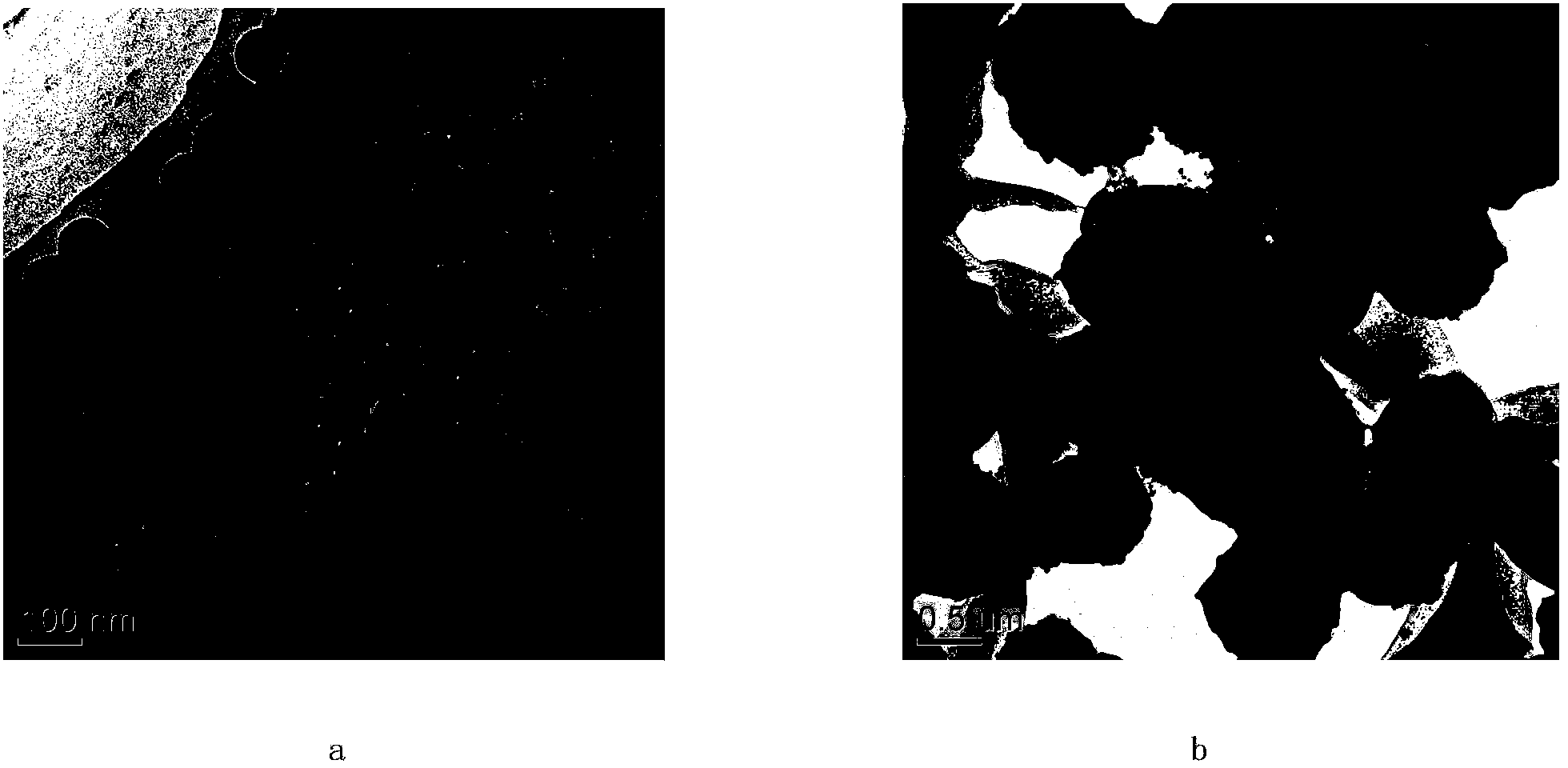

Surface-sulfonated monodisperse P(MMA-BA-St) polymer latex nanoparticles and preparation method thereof

ActiveCN102731702BReduce usageExcellent stability against harsh environmentsDevelopersPolymer scienceEmulsion

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com