Steel security door section and hemming process

A security, door leaf technology, applied in the direction of anti-war damage, anti-theft, sealing devices, etc., can solve the problems of door leaves leaving welding scars, reducing production efficiency, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

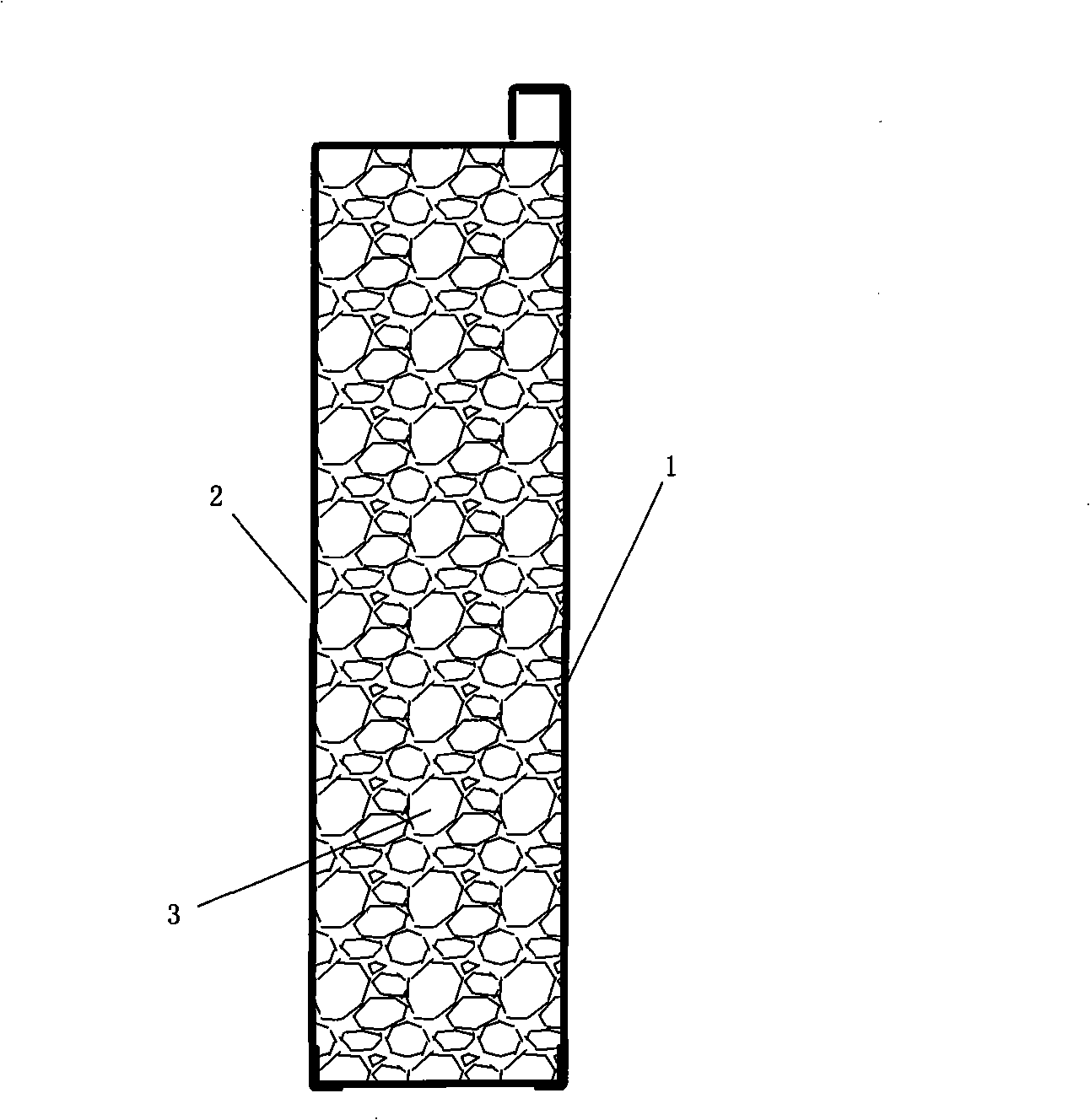

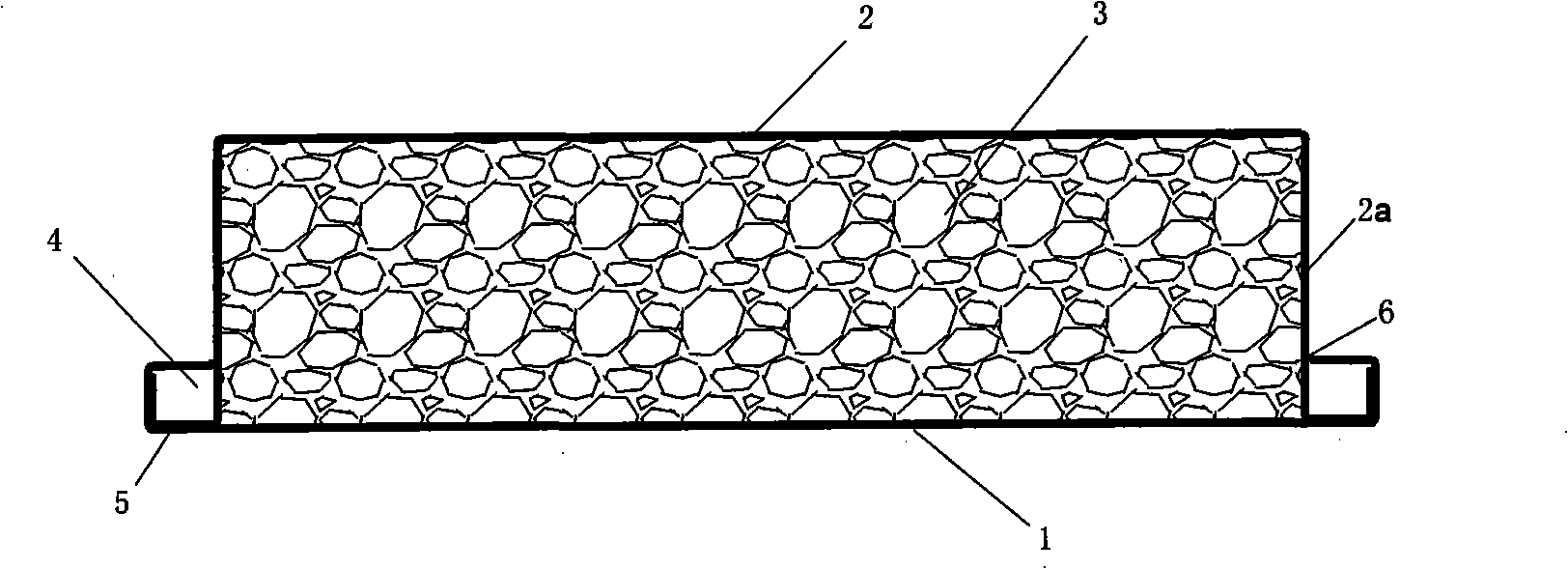

[0032] Embodiment 1 is the steel safety door leaf of prior art, as figure 1 , figure 2 shown. Existing safety door leaves are generally made of steel, including a front door panel 1 and a rear door panel 2. The cavity of the rear door panel is filled with soft fireproof door core material 3, and the edge of the front door panel is rolled inward to form a Parallel draw-in groove 4, rear door panel cavity opening side is provided with flange 5, and this flange 5 is inserted in the draw-in groove 4 of front door panel, and the flange 5 of rear door panel is clamped with the draw-in groove 4 of front door panel like this. The edge 4a of the slot of the front door panel is connected with the side wall 2a of the cavity of the rear door panel by welding spots 6 .

[0033] The door leaf of this structure has the following disadvantages. The combination between the rear door panel 2 and the front door panel 1 is mainly due to the elasticity of the cavity side wall 2a of the rear doo...

Embodiment 2

[0035] Embodiment 2 is the steel safety door leaf among the present invention, as image 3 , Figure 4 , Figure 5 , Figure 6, Figure 7, Figure 8 shown. A steel safety door leaf, comprising a front door panel 7 and a rear door panel 8, the cavity of the rear door panel is filled with a hard fireproof door core material 9, the overall width of the front door panel 7 is 933cm, the length is 1999cm, the overall width of the rear door panel 8 The width is 913cm and the length is 1979cm. The four edges 7a of the front door panel are all wider than the four flanges of the rear door panel by 10d 10cm, and the edges 7a of the front door panel are wider than the rear door panel. A three-layer sandwich-shaped wrapping edge 11 is formed at the upper part; the three-layer sandwich-shaped wrapping edge 11 is bent toward the opposite direction of the cavity opening of the rear door panel, and forms a 90-degree bend with the main body of the front door panel. In this way, the three-layer...

Embodiment 3

[0037] Embodiment 3 is the hemming process of the steel safety door leaf in the present invention, as shown in Fig. 6 , Fig. 7 and Fig. 8 .

[0038] Hemming process of steel safety door leaves:

[0039] The first step is to bend the edge 7a of the front door panel upwards, and the bending angle is ≥90°;

[0040] In the second step, attach one side of the cavity opening of the rear door panel to the side where the edge of the front door panel bends, and the flange 8d of the rear door panel is bonded to the front door panel 7;

[0041] The third step is to fold the bent portion 7a of the front door panel inwards, and cover the edge of the flange 8d of the rear door panel to form a three-layer sandwich-like wrapping edge 11;

[0042] The fourth step is to bend the three-layer sandwich-like wrapping 11 toward the opposite direction of the cavity opening of the rear door panel, and the overall bending angle is 90 degrees, so that a groove 10 is formed at the edge of the rear door pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com