A kind of spraying tube winding protection device

A protection device and tube technology, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, can solve the problems of reducing product quality and affecting the aesthetics of transparent fiber-reinforced PVC hoses, so as to ensure the quality of products quality, reduce the probability of contamination, and enhance the effect of protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

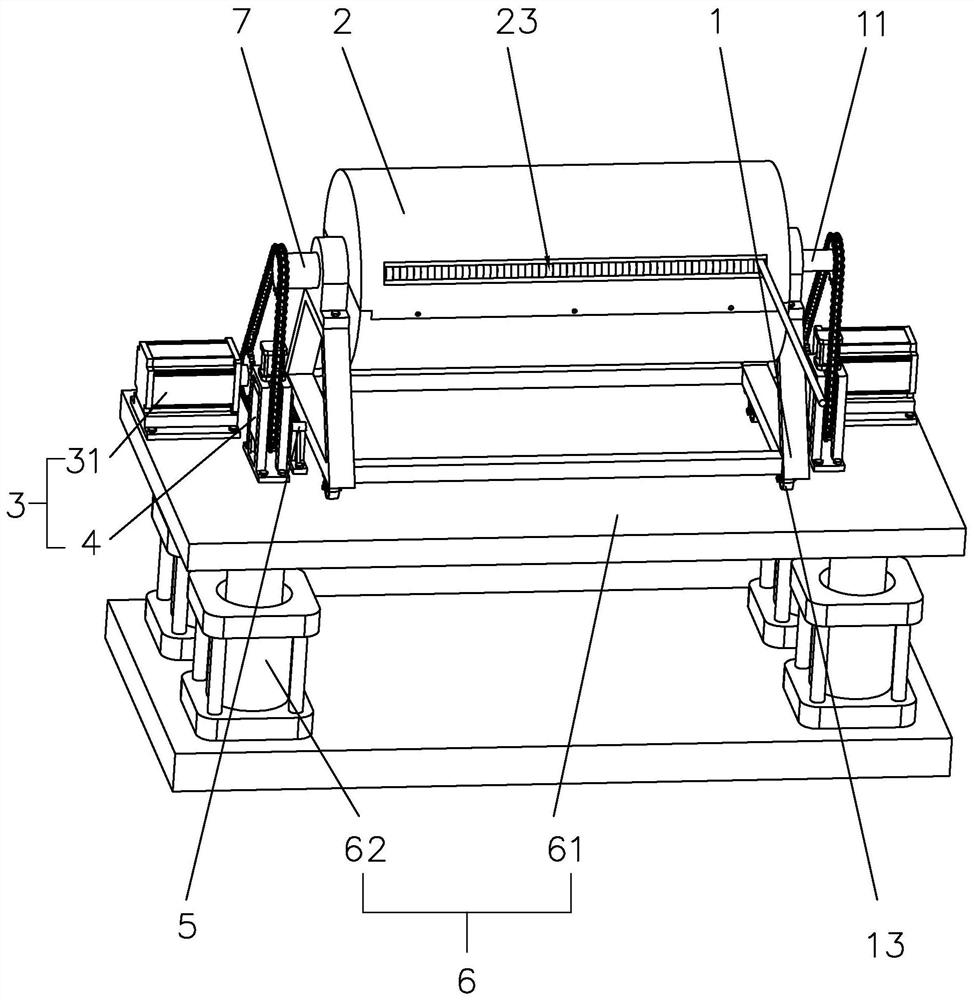

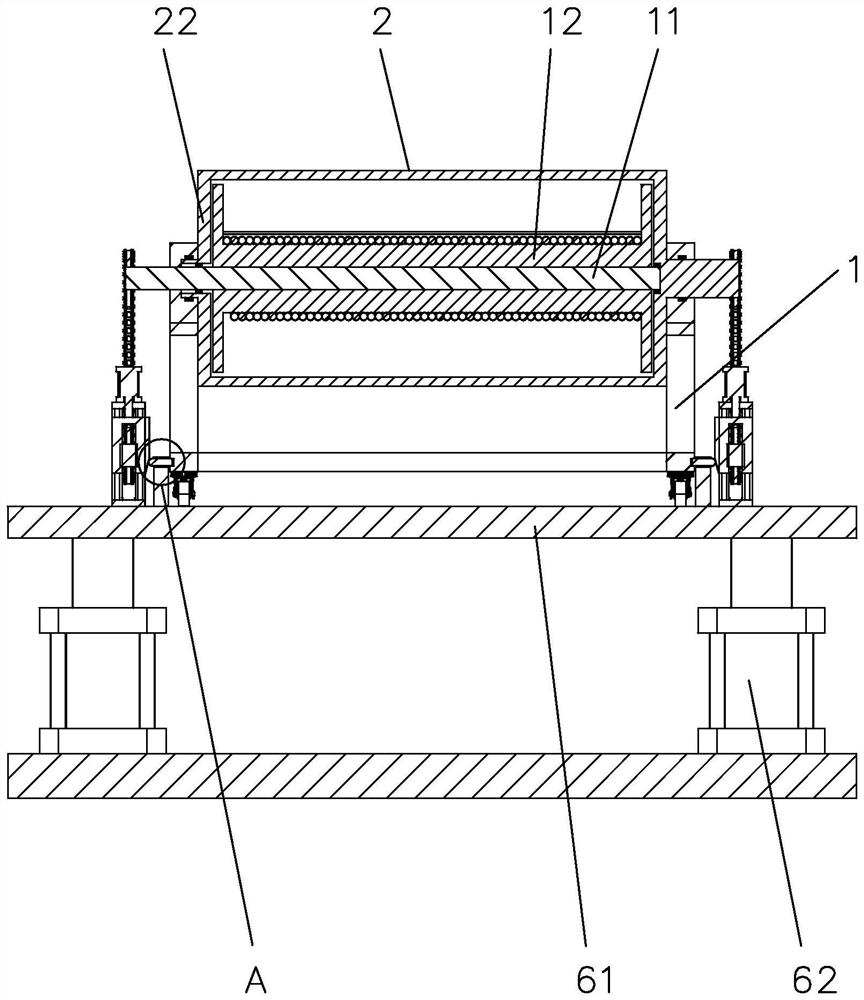

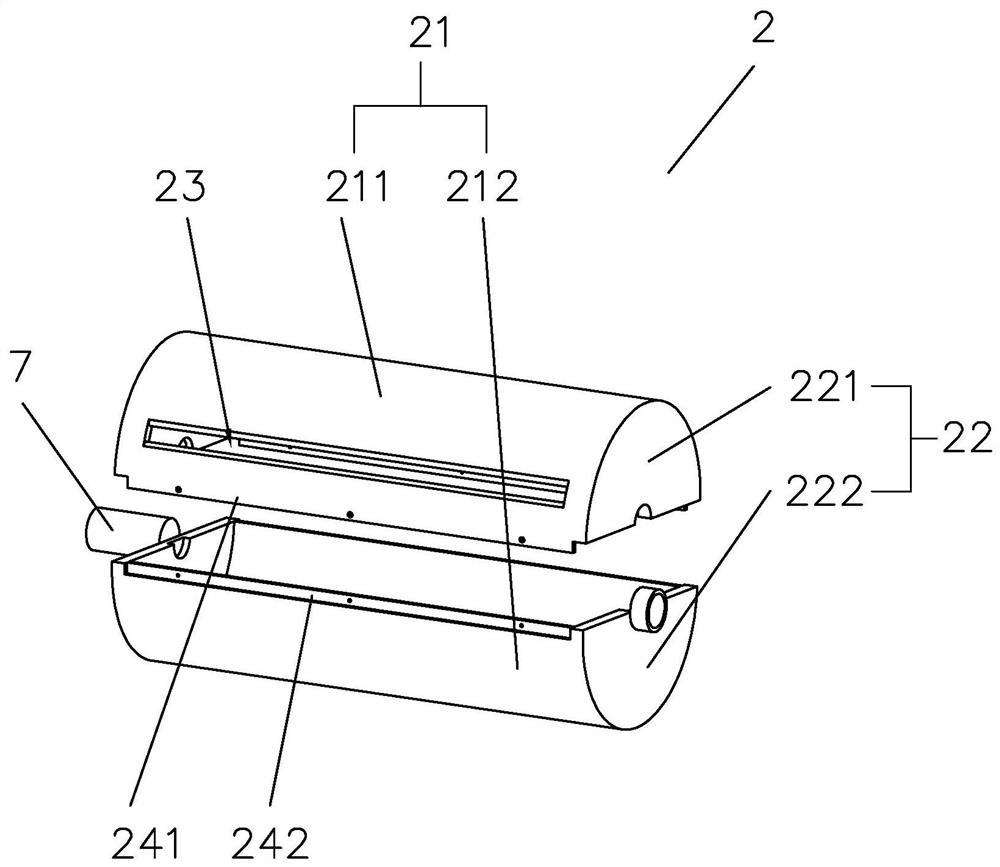

[0035] refer to figure 1 and figure 2 , which is a rewinding protection device for spraying tubes disclosed in the present invention, comprising a bracket 1 and a lifting mechanism 6, an installation pit for installing the lifting mechanism 6 is provided on the ground, a roller 13 is provided on the bracket 1, and a retracting mechanism is provided on the bracket 1. The reel 11 and the winding roller 12 fixedly connected with the winding shaft 11 are also provided with a protective tube 2 concentrically arranged with the winding roller 12 and a rotating member 7 for rotating the protective tube 2 on the support 1, and the winding roller 12 is located in the protective Inside the tube 2, the protective tube 2 is provided with a tube inlet groove 23. The upper and lower surfaces of the pipe inlet groove 23 are arc-shaped and covered with a polytetrafluoroeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com