A sealed radioactive source of a betavoltaic isotope battery and a preparation method thereof

A technology of isotope battery and radioactive source, which is applied in the field of sealed radioactive source of radioisotope battery and its preparation, can solve the problems of not meeting the requirements of radioisotope battery, low radioactivity loading, and low surface emissivity, etc. Achieve the effect of low cost, cost reduction and high surface emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

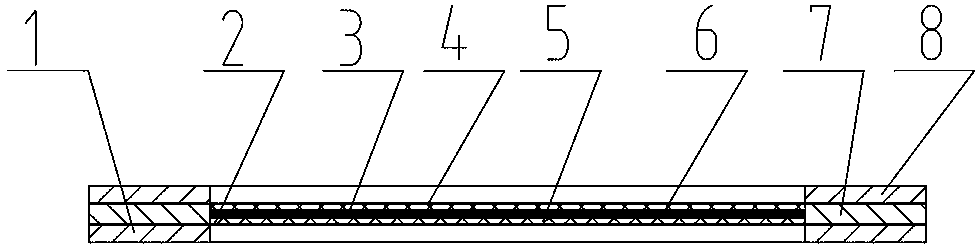

[0024] figure 1 It is the overall schematic diagram of the sealed radioactive source used in the radioisotope battery.

[0025] Such as figure 1 Among them, the lower metal film 2 and the upper metal film 4 are titanium films with a thickness of 10 μm; the lower metal support ring 1, the middle metal support ring 7 and the upper metal support ring 8 are titanium rings with a thickness of 0.3 mm and a ring width of 1 mm; source core 3 is 147 Pm radiation source; the lower organic polymer film 5 and the upper and lower organic polymer film 6 are polymethyl methacrylate with a molecular weight of 300.

[0026] The preparation steps are as follows:

[0027] Use a 10ml volumetric flask to prepare a 10g / l polymethylmethacrylate / chloroform solution. high specific activity 147 The Pm solution was diluted to 1 mCi / μl. The titanium film is attached to the circular titanium ring and laser welded to form two upper and lower shells. Add 150 μl of polymethylmethacrylate / chloroform so...

Embodiment 2

[0029] figure 1 Among them, the lower metal film 2 and the upper metal film 4 are aluminum films with a thickness of 15 μm; the lower metal support ring 1, the middle metal support ring 7 and the upper metal support ring 8 are nickel rings with a thickness of 1.0 mm and a ring width of 1.5 mm; Radioactive source core 3 is 90 The Sr radiation source; the lower organic polymer film 5 and the upper and lower organic polymer film 6 are polyimide / chloroform solutions with a molecular weight of 3000.

[0030] The preparation steps are as follows:

[0031] A 15 g / l polyimide / chloroform solution with a molecular weight of 3000 was prepared in a 10 ml volumetric flask. high specific activity 90The Sr solution was diluted to 0.5 mCi / μl. The aluminum film is attached to the square titanium metal ring and laser welded to form two upper and lower shells. Add 300 μl of polyimide / chloroform solution dropwise to the lower shell. Put the 170 μm thick cellulose material into the lower she...

Embodiment 3

[0033] figure 1 Among them, the lower metal film 2 and the upper metal film 4 are titanium films with a thickness of 10 μm; the lower metal support ring 1, the middle metal support ring 7 and the upper metal support ring 8 are titanium rings with a thickness of 0.8 mm and a ring width of 2 mm; source core 3 is 63 Ni radiation source; the lower organic polymer film 5 and the upper and lower organic polymer film 6 are polystyrene acetonitrile solutions with a molecular weight of 15,000.

[0034] The preparation steps are as follows:

[0035] Use a 10ml volumetric flask to prepare a 15g / l polystyrene / acetonitrile solution. high specific activity 63 The Ni solution was diluted to 50 μCi / μl. The titanium film is attached to the square titanium metal ring and laser welded to form two upper and lower shells. Add 100 µl of polystyrene / acetonitrile solution dropwise to the lower shell. Put the 210 μm thick cellulose material into the lower shell and add 300 μl of 63 Ni solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com