Surface-sulfonated monodisperse P(MMA-BA-St) polymer latex nanoparticles and preparation method thereof

A nano-latex and polymer technology, used in instruments, optics, electrography, etc., can solve the problems of harsh environment requirements, increase product production costs, poor stability against harsh environments, etc., and achieve high resistance to harsh environments. , the effect of simplifying the production process and reducing the expected cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

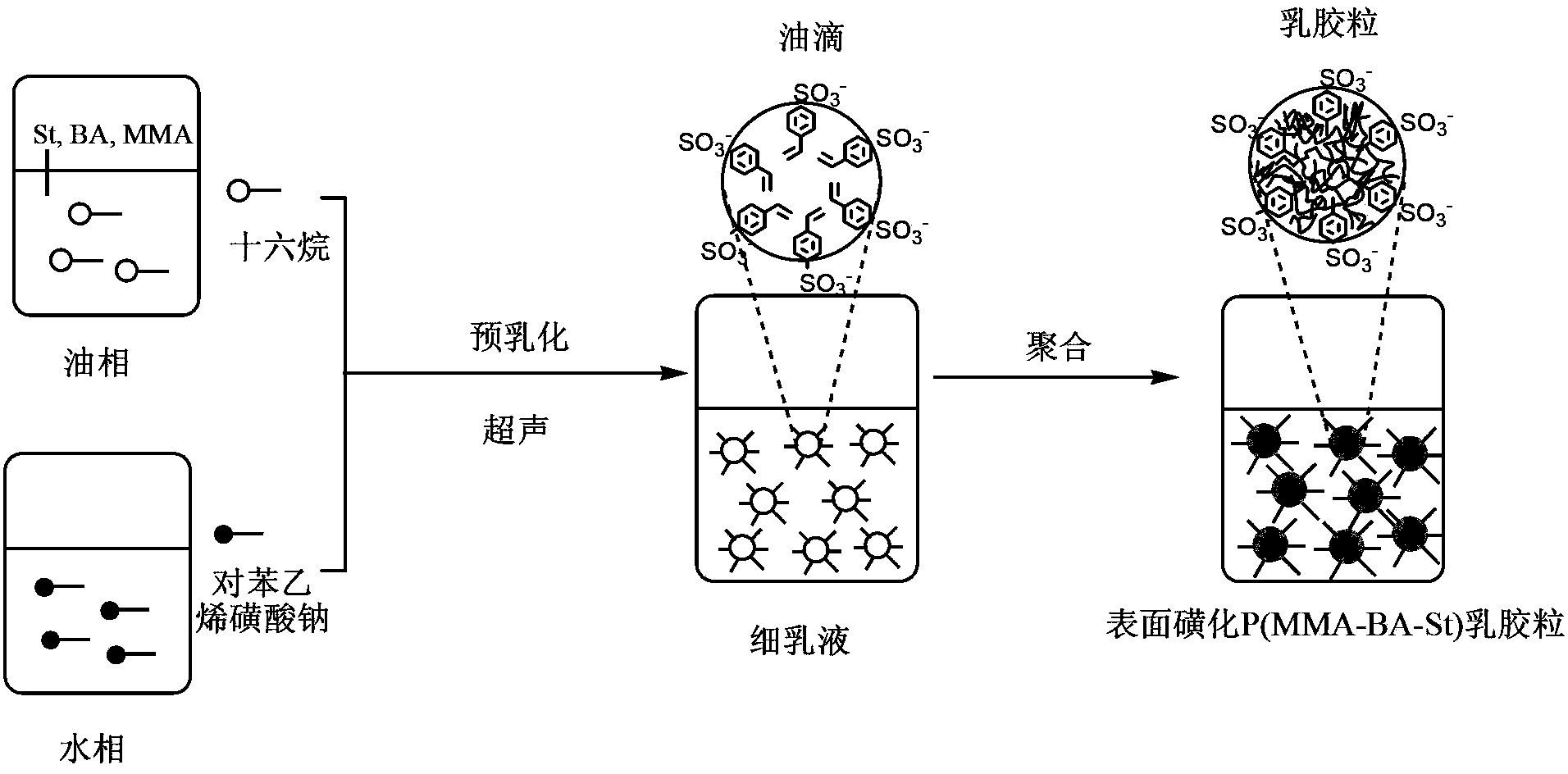

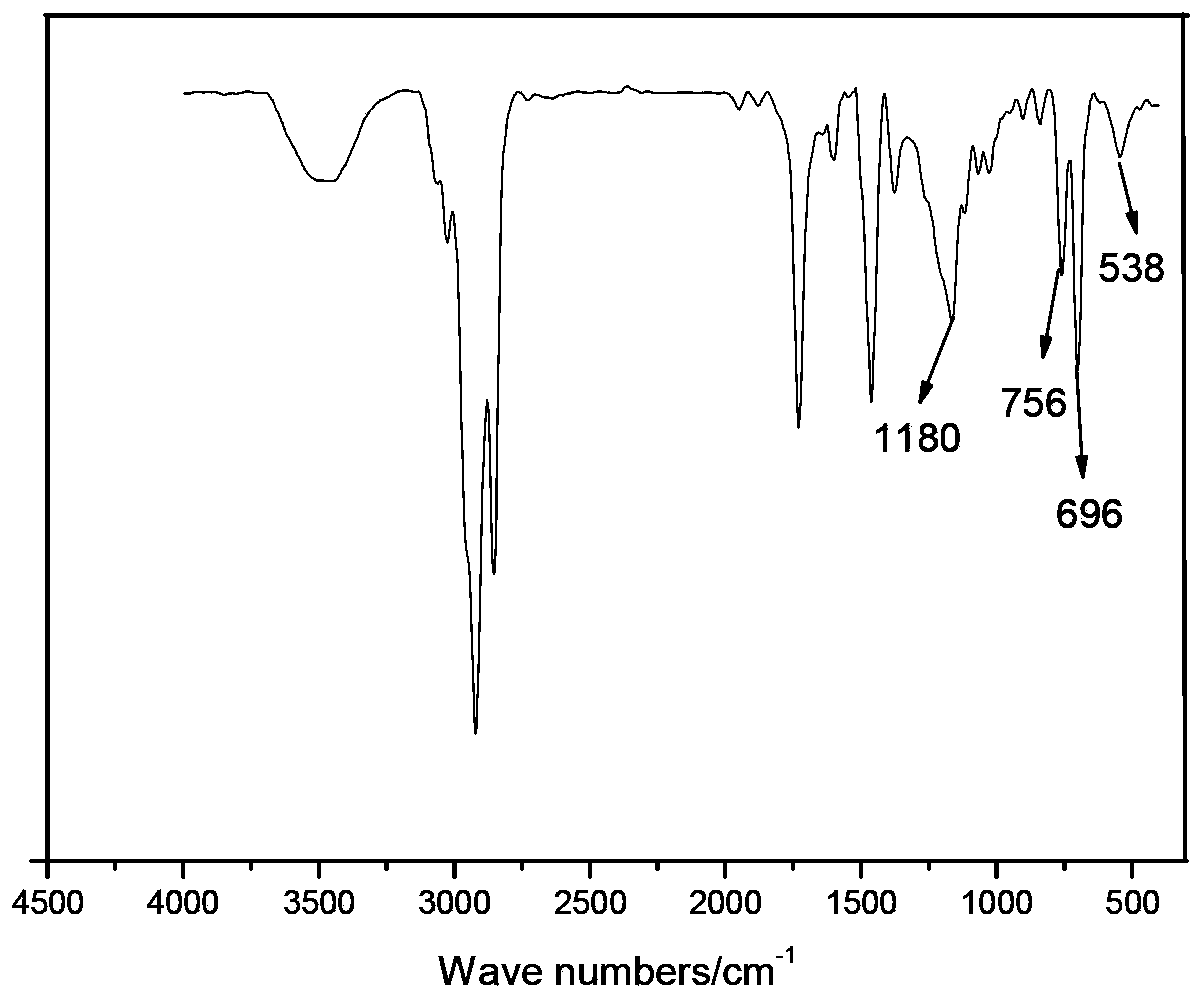

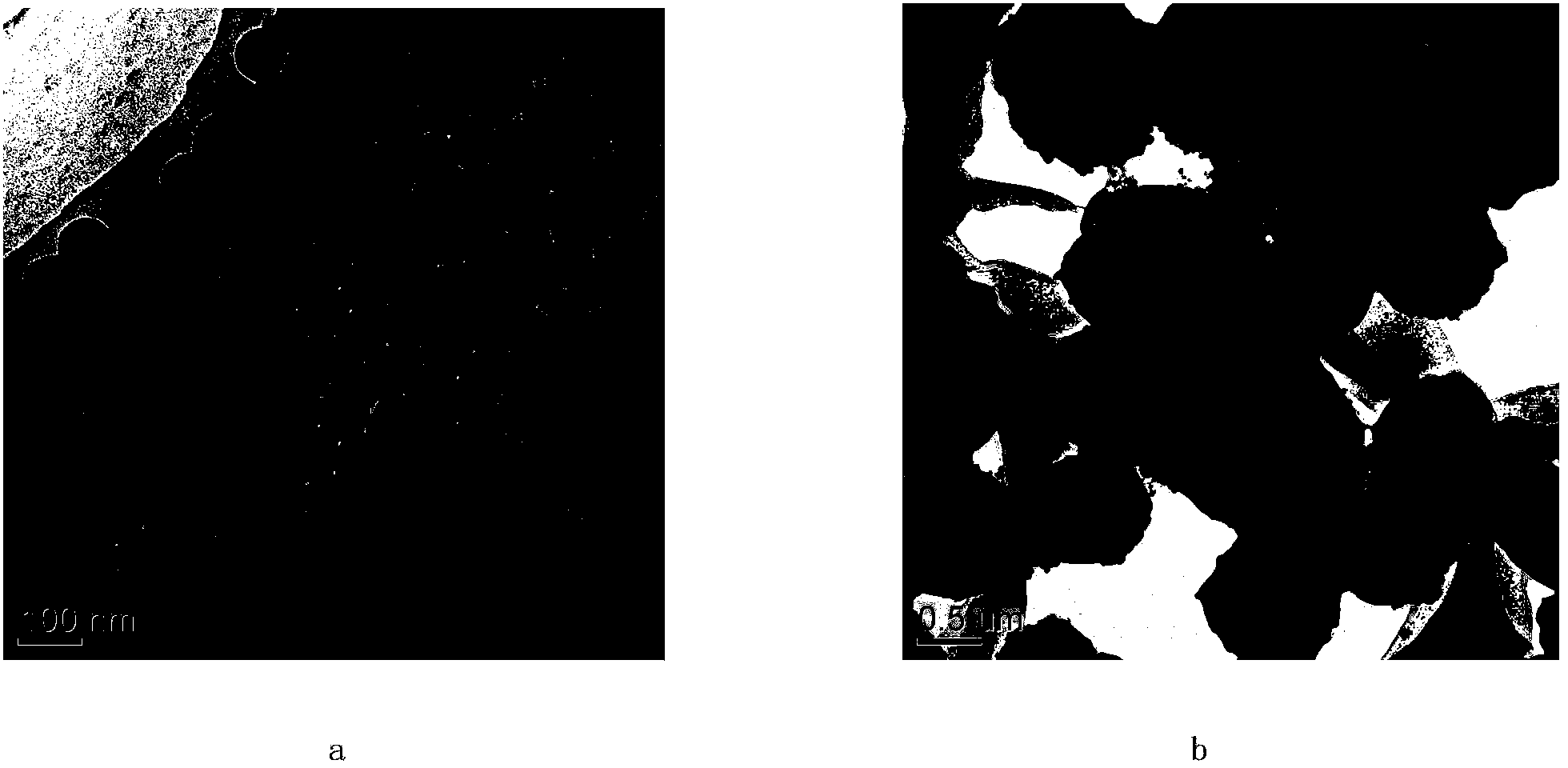

[0043] In a container equipped with an electric stirrer, condensed water, and a thermometer, add 0.33 g of reactive surfactant sodium p-styrenesulfonate and deionized water to fully dissolve the sodium p-styrenesulfonate at room temperature. Mix 1.0g of methyl methacrylate, 3.0g of butyl acrylate, 6.67g of styrene and 0.55g of co-emulsifier hexadecane and add them to the above-mentioned aqueous solution of sodium p-styrenesulfonate, at 40°C, 500rpm / Stir and pre-emulsify for 15 minutes under the condition of min, and then use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd. to ultrasonic fine emulsify for 10 minutes under the condition of output power 100%. Then transfer the system to a water bath with a set temperature of 70°C. Under the stirring condition of 300rpm / min, add 10.55g of potassium persulfate water-soluble (including 0.55g of potassium persulfate and 10.0g of water) dropwise to the system within 5min, and continue Reaction 3h...

Embodiment 2

[0046] In a container equipped with an electric stirrer, condensed water, and a thermometer, add 0.55 g of reactive surfactant sodium p-styrenesulfonate and deionized water to fully dissolve the sodium p-styrenesulfonate at room temperature. Mix 1.0g of methyl methacrylate, 3.0g of butyl acrylate, 6.45g of styrene and 0.55g of co-emulsifier hexadecane and add them to the above aqueous solution of sodium p-styrene sulfonate, at 40°C, 500rpm / Stir and pre-emulsify for 15 minutes under the condition of min, and then use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd. to ultrasonic fine emulsify for 10 minutes under the condition of output power 100%. Then transfer the system to a water bath with a set temperature of 70°C. Under the stirring condition of 300rpm / min, add 10.55g of potassium persulfate water-soluble (including 0.55g of potassium persulfate and 10.0g of water) dropwise to the system within 5min, and continue Reaction 3h. After ...

Embodiment 3

[0049] In a container equipped with an electric stirrer, condensed water, and a thermometer, add 0.77 g of reactive surfactant sodium p-styrenesulfonate and deionized water to fully dissolve the sodium p-styrenesulfonate at room temperature. Mix 1.0g of methyl methacrylate, 3.0g of butyl acrylate, 6.23g of styrene and 0.55g of co-emulsifier hexadecane and add them to the above aqueous solution of sodium p-styrenesulfonate, at 40°C, 500rpm / Stir and pre-emulsify for 15 minutes under the condition of min, and then use the KQ-300DE ultrasonic instrument produced by Kunshan Ultrasonic Instrument Co., Ltd. to ultrasonic fine emulsify for 10 minutes under the condition of output power 100%. Then transfer the system to a water bath with a set temperature of 70°C. Under the stirring condition of 300rpm / min, add 10.55g of potassium persulfate water-soluble (including 0.55g of potassium persulfate and 10.0g of water) dropwise to the system within 5min, and continue Reaction 3h. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com