Method for manufacturing micro-mechanical cantilever beam array with substrate silicon as fixing column

A manufacturing method and a cantilever beam technology are applied in the process, microstructure technology, microstructure device and other directions for producing decorative surface effects, which can solve the problems of cumbersome time-consuming, unsuitable for large-scale production, etc., and achieve low cost and high strength. The effect of practical value and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

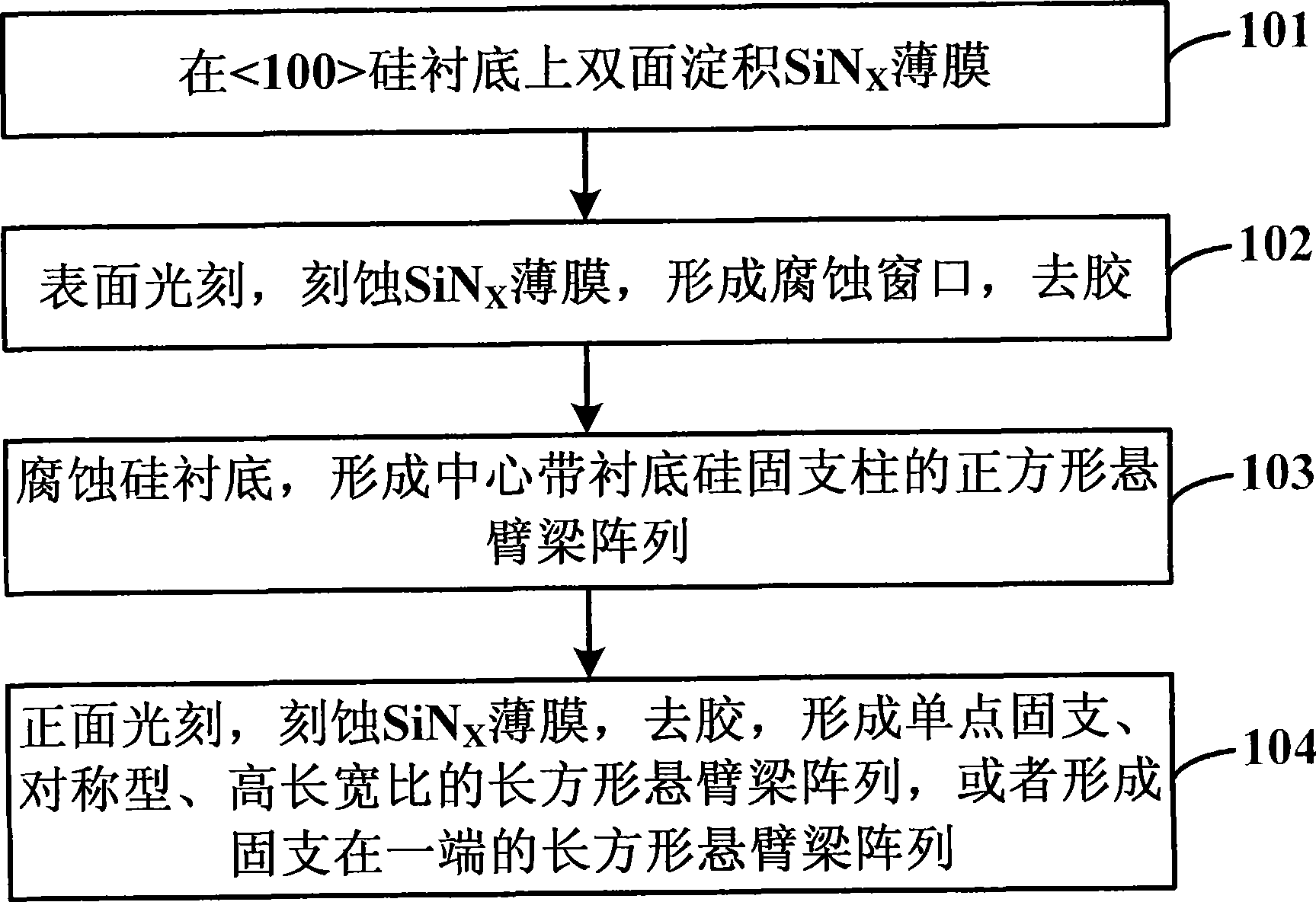

[0025] Such as figure 1 as shown, figure 1 It is a flow chart of a method for manufacturing a micromechanical cantilever array based on substrate silicon as a fixed support provided by the present invention, and the method includes:

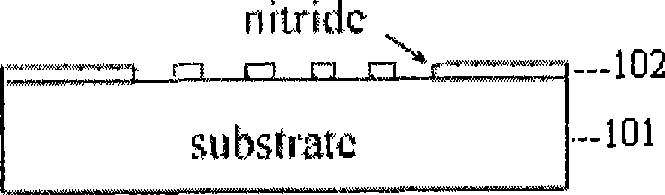

[0026] Step 101: Deposit SiN on both sides of the silicon substrate X Thin film; in this step, the LPCVD method is used for deposition.

[0027] Step 102: surface photolithography, etching SiN X thin film, form the corrosion window, and remove the glue; in this step, SF 6 Gas, isotropic etching of SiN at a flow rate of 60 to 70sccm and a power of 60 to 70w X The thin film reaches the silicon substrate, forming an etching window.

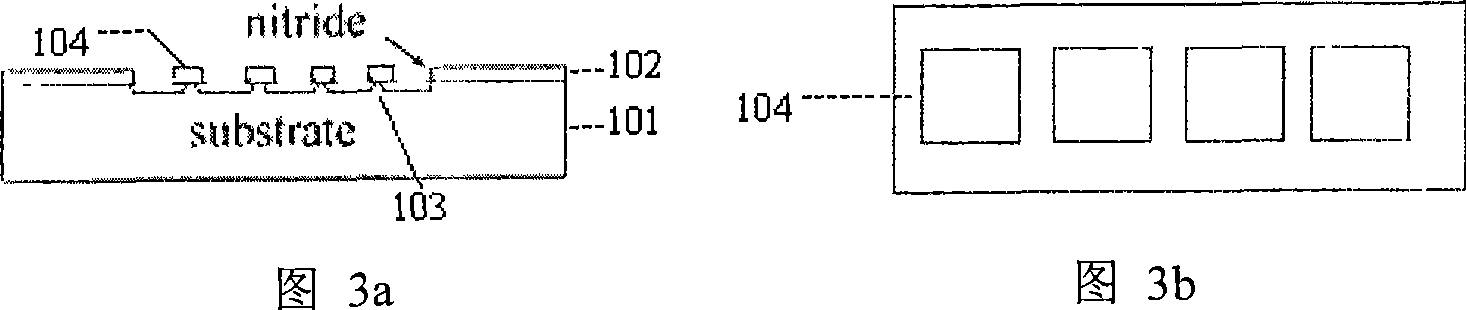

[0028] Step 103: Etching the silicon substrate to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com