One-way low-voltage TVS device and manufacturing method thereof

A low-voltage, device technology, applied in the field of unidirectional low-voltage TVS devices and their manufacture, can solve problems such as waste, misoperation energy, device leakage increase, etc., and achieve the effect of simple and easy manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

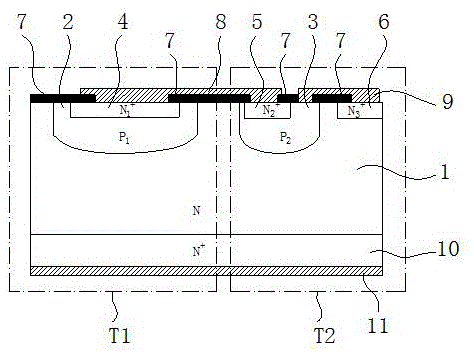

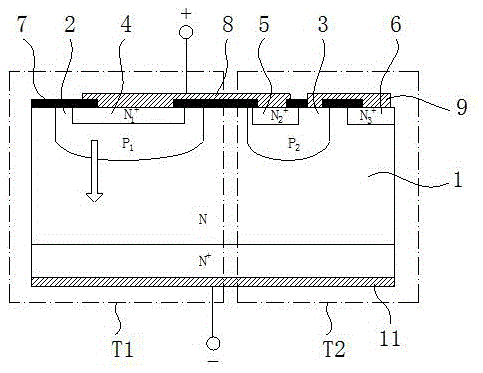

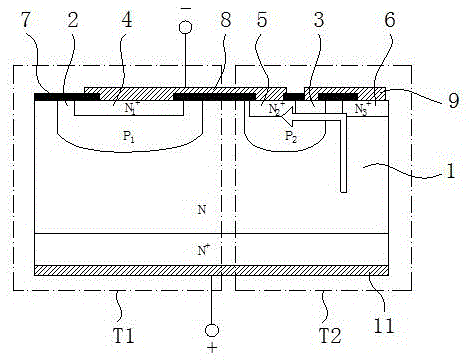

[0029] see figure 1 , a unidirectional low-voltage TVS device, including an N-type silicon chip 1, which is provided with a P 1 doped region 2 and P 2 Doped region 3, P 1 Doped region 2 is provided with N 1 + Doped region 4, P 2 Doped region 3 is provided with N 2 + Doped region 5, located at P 2 Doped region 3 is away from P 1 The N-type silicon wafer 1 on one side of the doped region 2 is provided with N 3 + The doped region 6; the front side of the N-type silicon chip 1 is provided with an oxide layer 7, and the upper surface of the oxide layer 7 is provided with an upper metallization electrode 8 and an interconnection metal layer 9, and the upper metallization electrode 8 passes through the opening of the oxide layer 7 hole with N 1 + doped region 4 and N 2 + The upper surface of the doped region 5 is connected, and the interconnection metal layer 9 is connected to the P 2 doped region 3 and N 3 + The upper surface of the doped region 6 is connected; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com