An automatic production device for all-wood discs

A production device and wooden disc technology, which is applied in wood processing equipment, manufacturing tools, etc., can solve the problems of not being able to meet the requirements of modern industrial production, manual production is time-consuming and labor-intensive, and disc specifications are not uniform, so as to shorten production preparation Time saving, labor cost saving, high controllability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

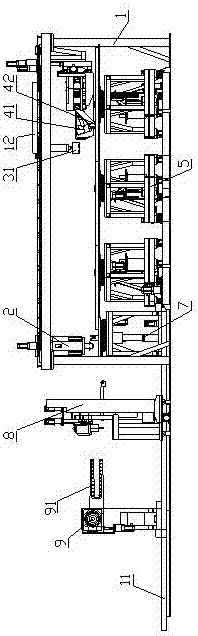

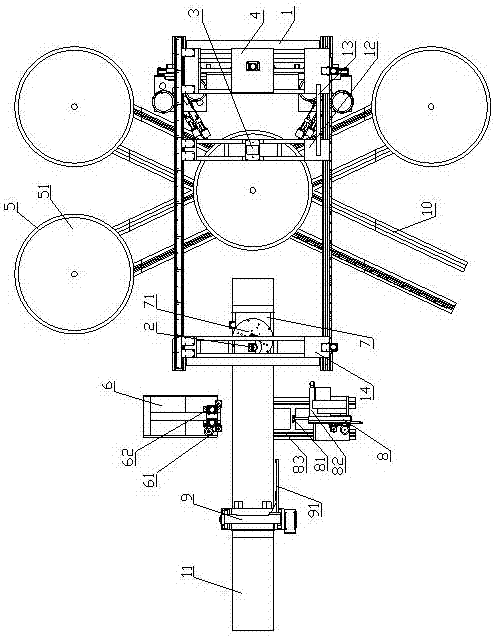

[0014] Such as figure 1 and figure 2 As shown, an automatic production device for all wooden discs includes a frame 1, a cross rail 10 is provided at the bottom of the frame 1, and a conveying trolley 5 is respectively movable at each end of the cross rail 10, and a conveying trolley 5 is provided on the top of the conveying trolley 5 Place platform 51, the top two ends of frame 1 are provided with nailing machine 4 and cross arm II14 movable respectively, and nailing machine 4 is provided with two groups of nail arms 41 symmetrically near the side of cross arm II14, and the bottom of nail arm 41 is provided with There is a pressing wheel 42, the center of the cross arm II14 is provided with a cable hole drilling machine 2, the bottom of the cable hole drilling machine 2 is provided with a slotting trolley 7, the top of the slotting trolley 7 is provided with a slotting platform 71, and the bottom is provided with a straight line Guide rail 11, the linear guide rail 11 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com