Special portal type numerical-control milling machine for efficiently milling arc-shaped surface of tool

A CNC milling machine and milling edge technology, which is applied in the field of CNC milling machines, can solve the problems of large spacing, small number of clamping, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

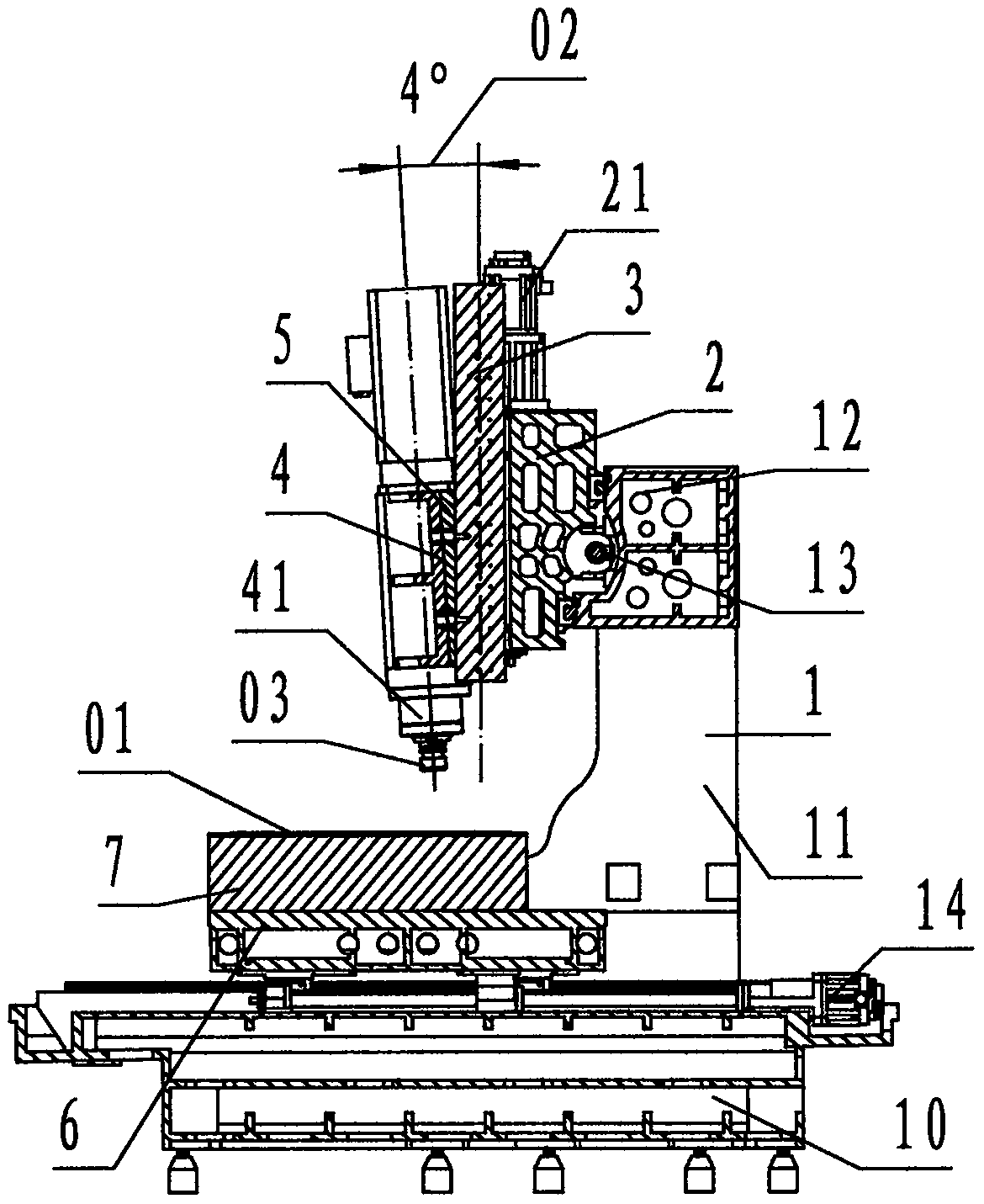

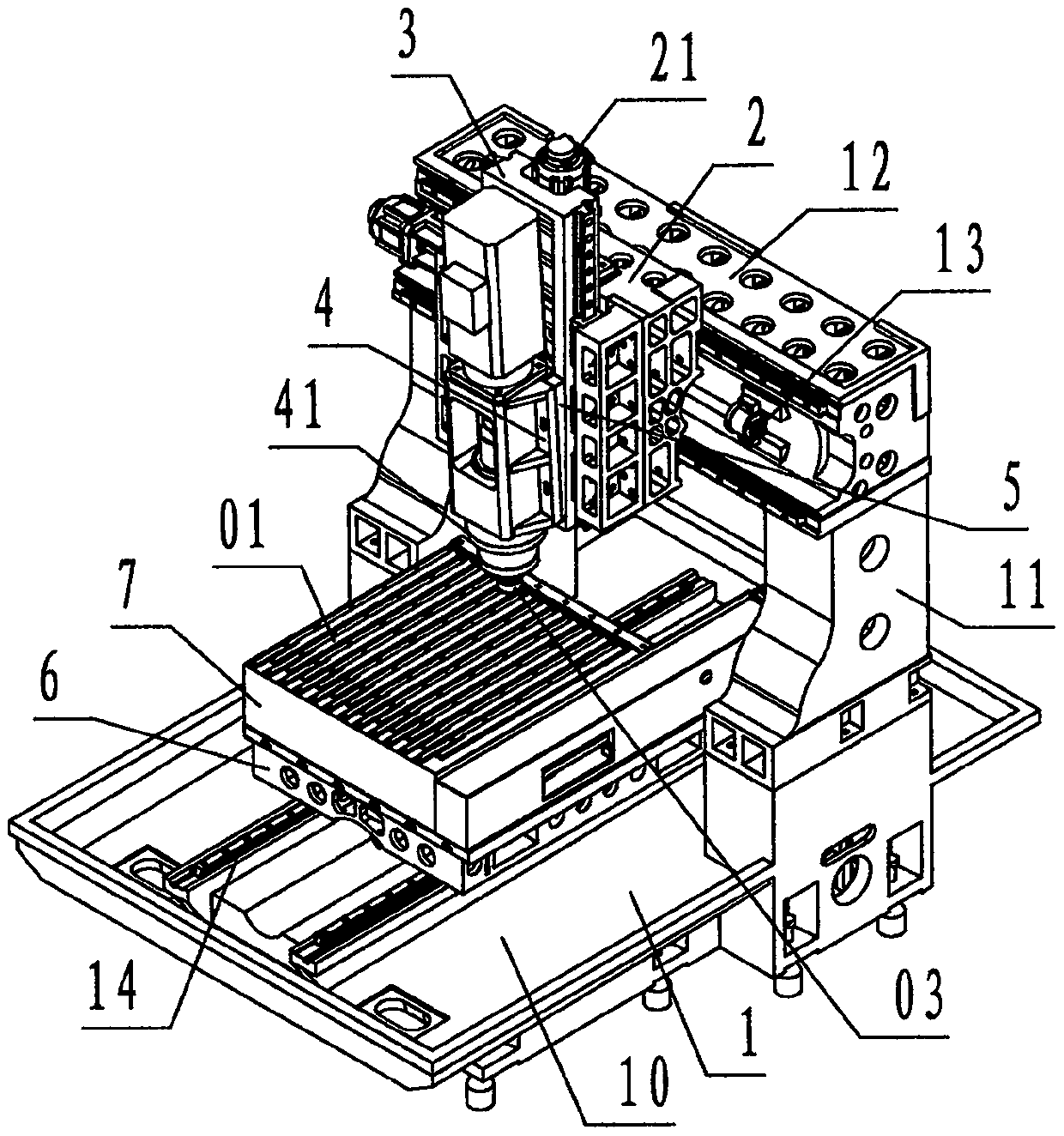

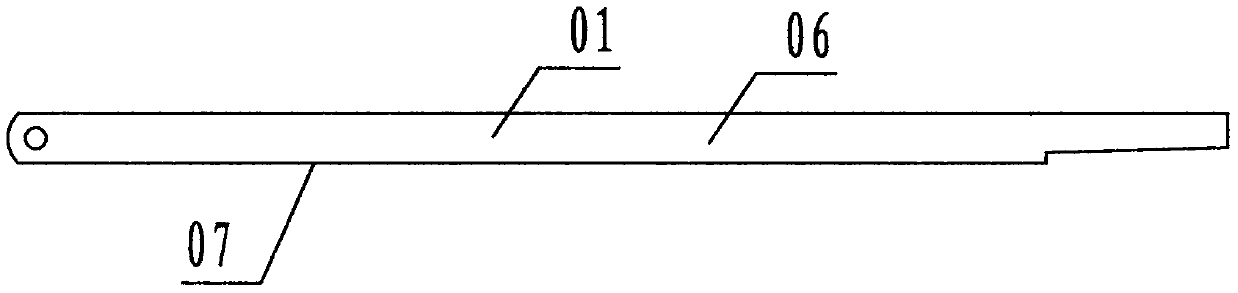

[0036] Refer to figure 1 , figure 2 , Image 6 , Figure 7 , The present invention is a special gantry-type CNC milling machine for high-efficiency milling and cutting tool arcs, including gantry bed 1, orthogonal carriage 2, Z-direction carriage 3, spindle seat 4, inclined iron 5, movable worktable 6 and Electromagnetic workbench 7, wherein: the gantry bed 1 is composed of a bed 10, a column 11, a beam 12, an X-axis 13, and a Y-axis 14. The Y-axis 14 is composed of a Y roller guide pair, Y The ball screw pair and the Y servo motor are formed, the Y axis 14 is arranged on the top of the bed 10 in the left and right direction, and the Y axis 14 is a mechanism that carries, guides, and drives the moving table 6 to move in the left and right directions; the X direction The shaft 13 is composed of X roller guide pair, X ball screw pair and X servo motor. The X axis 13 is arranged on the left side of the beam 12 along the front and rear direction. The X axis 13 is for carrying, gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com