Iron trough castable containing 70% or above of high-aluminum aggregates

A technology of iron trench castables and high-alumina aggregates, which is applied in the field of iron trench castables, can solve the problems of castable compactness and high-temperature performance, restricting the proportion of high-alumina aggregates added, and the amount of additions is difficult to exceed 50%. , to achieve excellent physical properties and high temperature performance, reduce the overall contracting cost of the iron trench, and achieve important economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

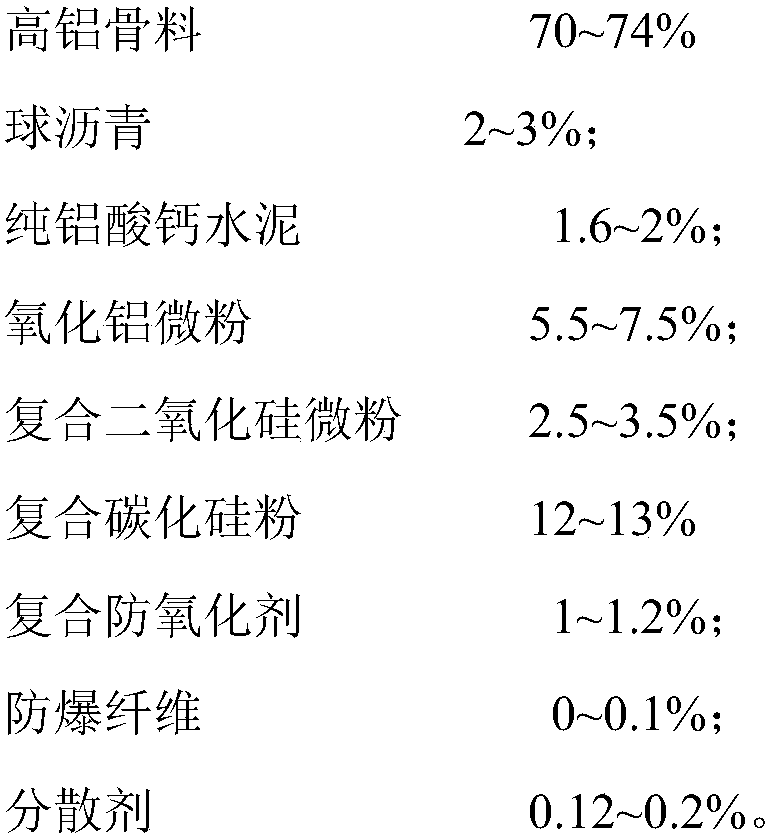

Embodiment 1

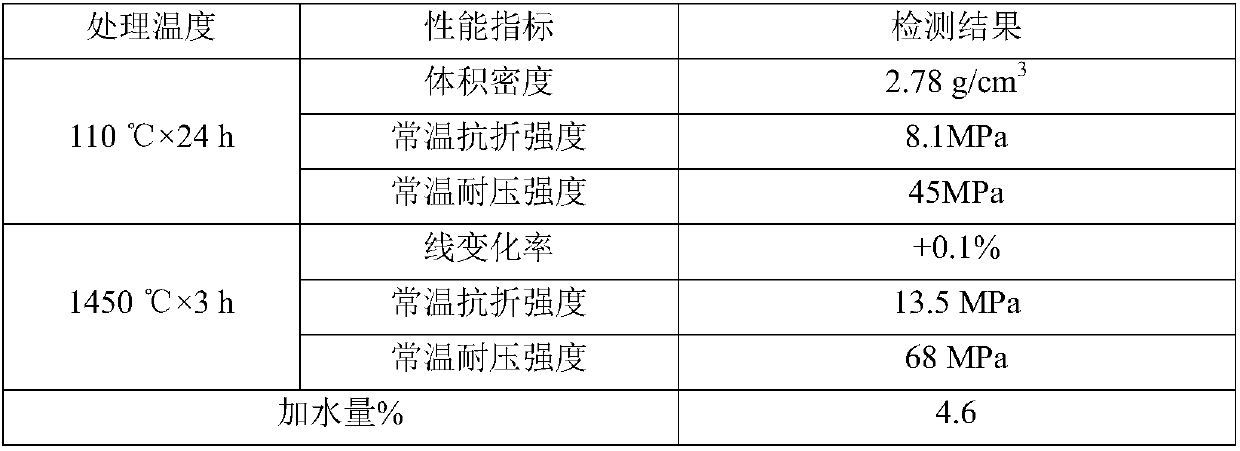

[0032] A iron ditch castable containing more than 70% high-alumina aggregate, each component and its mass percentage are: 74% of 88 high-alumina aggregate, 12% of composite silicon carbide powder, 2% of ball pitch, pure aluminum Calcium acid cement 1.83%, alumina micropowder 5.5%, composite silica micropowder 3.5%, composite antioxidant 1% (metal silicon powder 0.88%, metal aluminum powder 0.12%), explosion-proof fiber 0.05%, dispersant 0.12% (three Sodium polyphosphate 0.06%, sodium hexametaphosphate 0.06%); each raw material is weighed according to the above-mentioned ratio and fully mixed; then add water (the quality of water is 4.6% of the total mass of each raw material) and stir evenly before vibration molding; forming After the obtained sample was dried naturally for 24 hours, it was then heat-treated at 110°C for 24 hours to obtain a sample of iron trough castable containing 74% high alumina aggregate.

[0033] The performance test of the iron ditch castable sample con...

Embodiment 2

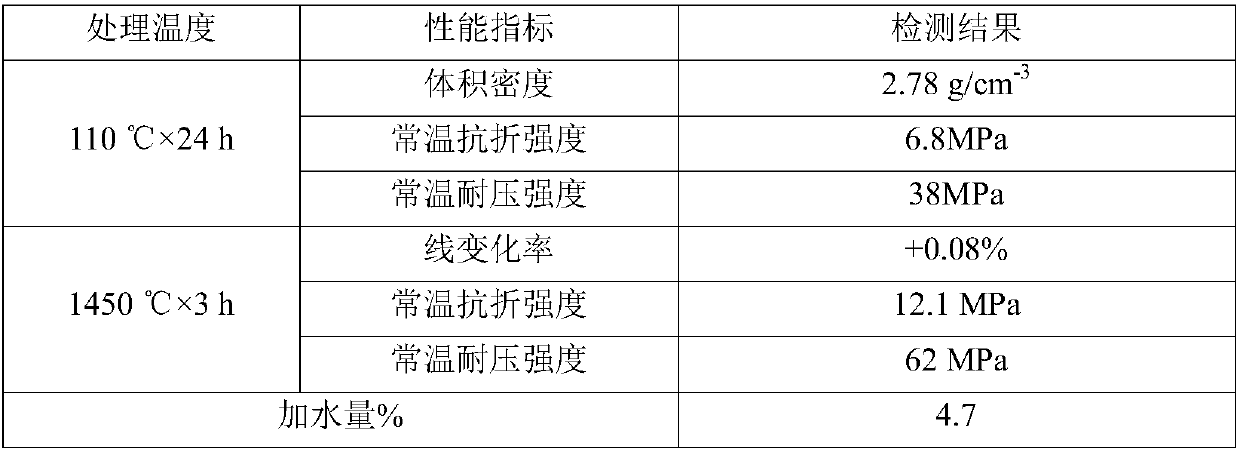

[0037] A iron ditch castable containing more than 70% high-alumina aggregate, each component and its mass percentage are: 72% of 88 high-alumina aggregate, 12.5% of composite silicon carbide powder, 2.5% of ball pitch, pure aluminum Calcium acid cement 1.64%, alumina micropowder 7.5%, composite silica micropowder 2.5%, composite antioxidant 1.1% (metal silicon powder 1%, metal aluminum powder 0.1%), explosion-proof fiber 0.1%, dispersant 0.16% (three Sodium polyphosphate 0.08%, sodium hexametaphosphate 0.08%); each raw material is weighed according to the above-mentioned ratio and fully mixed; then add water (the quality of water is 4.7% of the total mass of each raw material) and stir evenly before vibration molding; forming After the obtained sample was dried naturally for 24 hours, it was then heat-treated at 110°C for 24 hours to obtain a sample of iron trough castable containing 72% high alumina aggregate.

[0038] The iron ditch castable sample containing more than 70%...

Embodiment 3

[0042] A iron ditch castable containing more than 70% high-alumina aggregate, each component and its mass percentage are: 70% of 88 high-alumina aggregate, 13% of composite silicon carbide powder, 3% of ball pitch, pure aluminum Calcium acid cement 2%, alumina micropowder 7.5%, composite silica micropowder 3%, composite antioxidant 1.2% (metal silicon powder 1.06%, metal aluminum powder 0.14%), explosion-proof fiber 0.1%, dispersant 0.2% (three Sodium polyphosphate 0.1%, sodium hexametaphosphate 0.1%); each raw material is weighed according to the above ratio and fully mixed; then add water (the quality of water is 4.6% of the total mass of each raw material) and stir evenly and vibrate to form; After the obtained sample was dried naturally for 24 hours, it was then heat-treated at 110°C for 24 hours to obtain a sample of iron trough castable containing 70% high alumina aggregate.

[0043] The iron ditch castable sample containing more than 70% high alumina aggregate prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com