Silicon carbide-magnesium aluminum spinel composite refractory material

A technology of magnesium aluminum spinel and refractory materials, which is applied in the field of refractory materials, can solve the problems of low operating temperature and poor slag resistance, and achieve high refractory performance, improved slag resistance, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

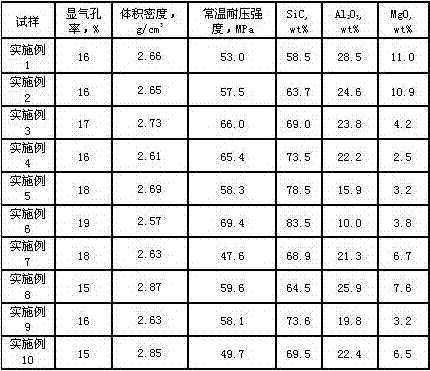

Examples

Embodiment 1

[0021] The chemical composition of the particle size greater than 10 μm and less than or equal to 90 μm was weighed as w (Al 2 o 3 +MgO)≥99.5%, Al 2 o 3 35 kg of ≈72% sintered magnesia-aluminum spinel fine powder, the chemical composition of which is greater than 43 μm and less than or equal to 74 μm is w (Al 2 o 3 ) ≥ 99.0% fused white corundum fine powder 3 kg, light-burned magnesia fine powder 1 kg, elemental Si fine powder 1 kg with a particle size greater than 5 μm and less than or equal to 15 μm, fully premixed by a ball mill to prepare matrix fine powder; w (SiC) ≥ 98.0% fused silicon carbide particles, of which 15 kg of particles with a particle size greater than 0.1 mm and less than or equal to 1 mm, 30 kg of particles with a particle size greater than 1 mm and less than or equal to 3 mm, 15 kg of particles with a particle size greater than 3 mm and less than or equal to 5 mm Add it to the wheel-type sand mixer and mix it evenly; add about 3 kg of binder phenoli...

Embodiment 2

[0023] The chemical composition of the particle size greater than 10 μm and less than or equal to 90 μm was weighed as w (Al 2 o 3 +MgO)≥99.5%, Al 2 o 3 ≈65% sintered magnesia-aluminum spinel fine powder 27 kg, the chemical composition of particle size greater than 43 μm and less than or equal to 74 μm is w (Al 2 o 3 ) ≥ 99.0% tabular corundum fine powder 5 kg, fused magnesia fine powder 1.5 kg, metal aluminum powder 1.5 kg with a particle size greater than 20 μm and less than or equal to 50 μm, fully premixed by a ball mill to prepare matrix fine powder; w (SiC) ≥ 98.0% fused silicon carbide particles, of which 15 kg of particles with a particle size greater than 0.1 mm and less than or equal to 1 mm, 30 kg of particles with a particle size greater than 1 mm and less than or equal to 3 mm, 25 kg of particles with a particle size greater than 3 mm and less than or equal to 4 mm Add it to the wheel-type sand mixer and mix it evenly; add about 4 kg of binder water-soluble ...

Embodiment 3

[0025] The chemical composition of the particle size greater than 10 μm and less than or equal to 74 μm was weighed as w (Al 2 o 3 +MgO)≥99.0%, Al 2 o 3 The chemical composition of ≈85% fused magnesia-aluminum spinel fine powder 15 kg, particle size greater than 43 μm and less than or equal to 74 μm is w (Al 2 o 3 )≥99.0% fused white corundum fine powder 6 kg, particle size D 50 =5 μm, w (Al 2 o 3 )≥99.0% of α-Al 2 o 3 5 kg of fine powder, 2 kg of sintered magnesia fine powder, 1 kg of spherical graphite powder with a particle size greater than 30 μm and less than or equal to 50 μm, fully pre-mixed by a ball mill to prepare matrix fine powder; weigh w (SiC) ≥ 98.5% fused silicon carbide particles, of which 15 kg of particles with a particle size greater than 0.1 mm and less than or equal to 0.5 mm, 20 kg of particles with a particle size greater than 0.5 mm and less than or equal to 1.43 mm, 35 kg of particles with a particle size greater than 1.43 mm and less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com