Alumina-spinel-carbon brick containing aluminachrome slag and preparation method of alumina-spinel-carbon brick

A technology of aluminum spinel carbon brick and aluminum chromium slag, which is applied in the field of refractory materials, can solve the problems of unseen products, achieve excellent slag erosion resistance, improve density and slag resistance, enhance erosion resistance and Effect of slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

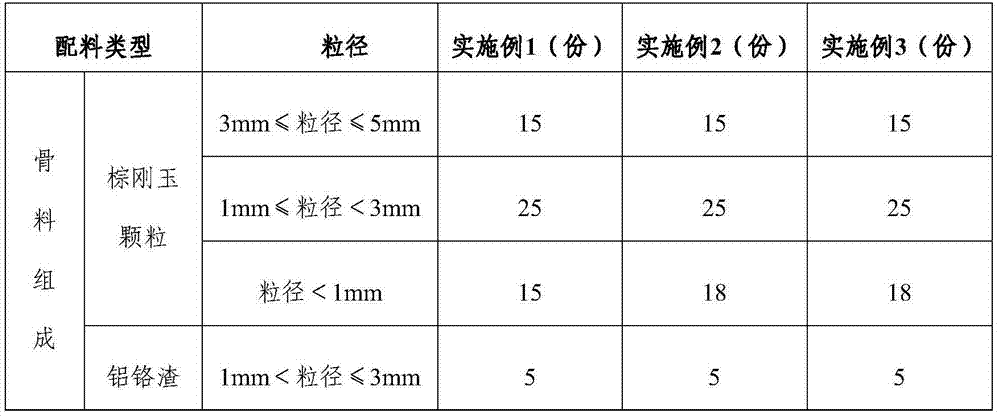

[0030] The batching that embodiment 1-3 adopts and the number of parts are as shown in the following table:

[0031]

[0032]

Embodiment 4-6

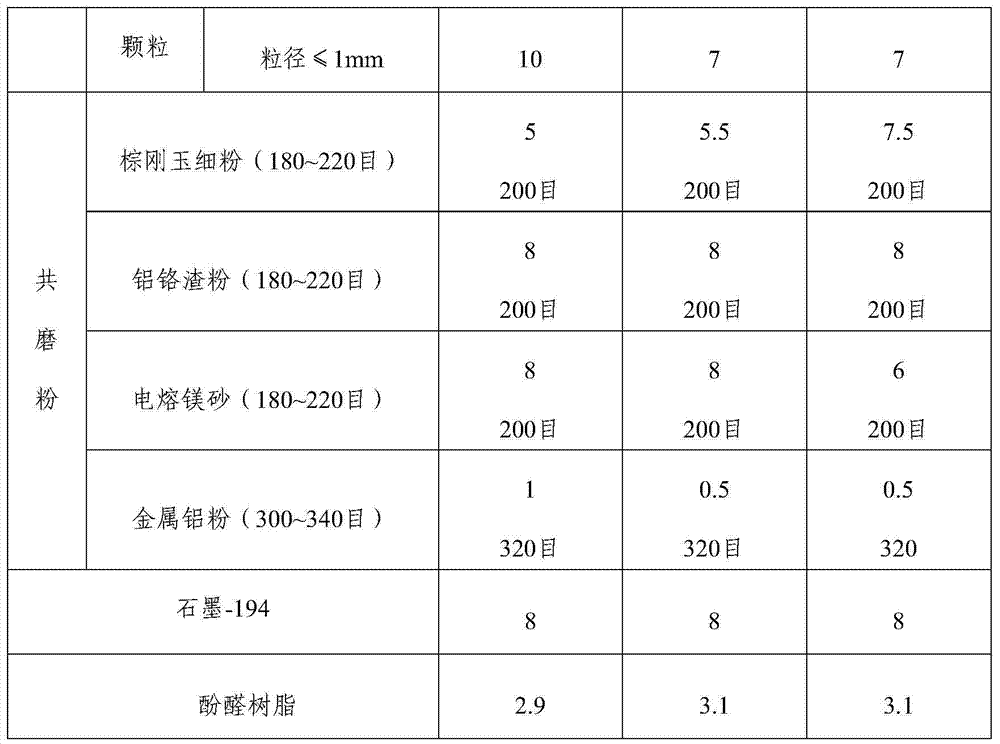

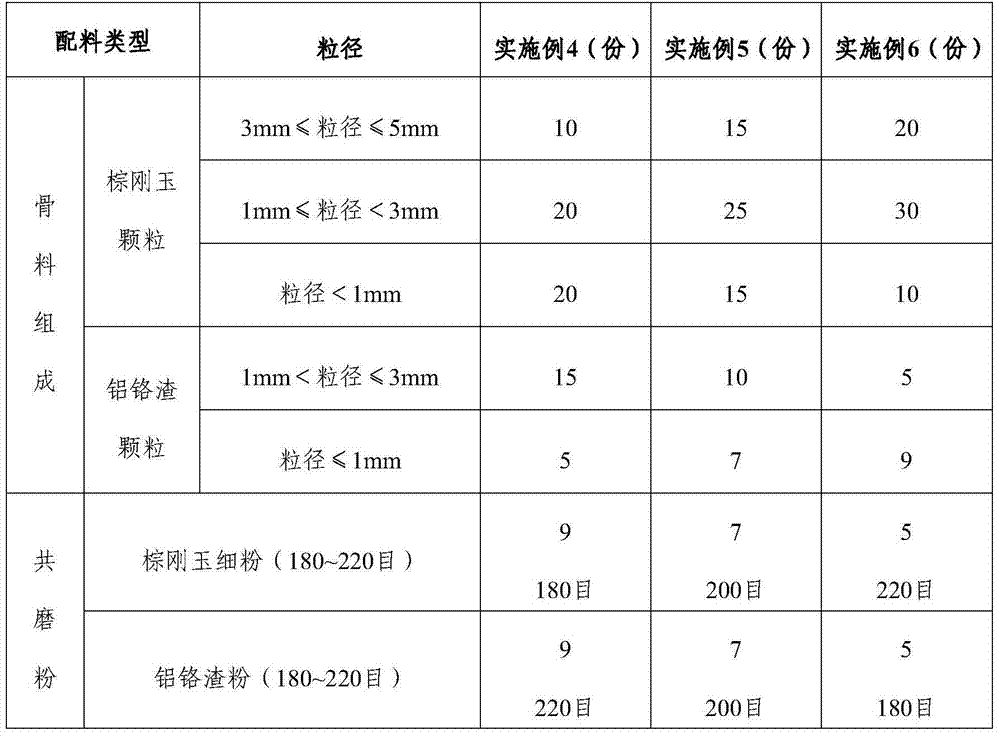

[0034] The batching that embodiment 4-6 adopts and the number of parts are as shown in the following table:

[0035]

[0036]

Embodiment 7

[0038] The present embodiment is the preparation method of the aluminum spinel carbon brick containing aluminum chromium slag, specifically comprises the following steps:

[0039] (1) Co-grind brown corundum fine powder, aluminum chromium slag fine powder, fused magnesia fine powder and metal aluminum powder according to the proportioning amount, and mix them uniformly to make co-milling powder;

[0040] (2) Dry mix brown corundum particles and aluminum chrome slag particles for 3 minutes according to the proportion, then slowly add binder (phenolic resin) and graphite within 2 minutes, and finally add the co-milled powder obtained in step (1) and mix For 30 minutes, the discharge temperature is 50-60°C, and the semi-finished product is formed on a 630-ton brick press. The forming operation must follow the principle of cutting materials at four corners, light first and then heavy. Then heat treatment for more than 24 hours, wherein the temperature at the entrance of the kiln s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com