Novel acid furnace lining refractory material

A technology of acidic lining and refractory materials, which is applied in the field of acidic refractory lining materials for induction furnaces. It can solve the problems of large volume expansion and easy formation of cracks, and achieve the effects of improving compactness, prolonging service life, and improving volume density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Coarse crystalline quartz sand is selected as the raw material, and the mass percentage of each raw material is: 3-5mm high-purity microcrystalline quartz sand 21%; 1-2mm high-purity microcrystalline quartz sand 30%; 0-1mm semi-sintered microcrystalline quartz sand 22%; 325 mesh semi-sintered microcrystalline quartz sand 26%; boric anhydride (B 2 o 3 ) is 1%; special sintering agent XO is 0.05%. It is made through mineral processing, coarse crushing, material washing, fine crushing, sieving, testing, drying, testing, batching, mixing, testing, packaging and other steps.

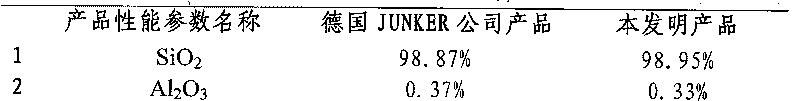

[0018] After testing, the product of the present invention is compared with the main performance of the product of JUNKER company in Germany as follows:

[0019]

[0020]

[0021] The above test data show that the thermal expansion (1000° C.) of the product of the present invention is lower than that of similar products of JUNKER, Germany, so the volume expansion produced in the use process dec...

Embodiment 2

[0023] Coarse crystalline quartz sand is selected as the raw material, and the mass percentage of each raw material is: 3-5mm high-purity microcrystalline quartz sand 20%; 1-2mm high-purity microcrystalline quartz sand 30%; 0-1mm semi-sintered microcrystalline quartz sand 23%; 325 mesh semi-sintered microcrystalline quartz sand 26%; boric anhydride (B 2 o 3 ) is 1%; special sintering agent XO is 0.04%. It is made through mineral processing, coarse crushing, material washing, fine crushing, sieving, testing, drying, testing, batching, mixing, testing, packaging and other steps.

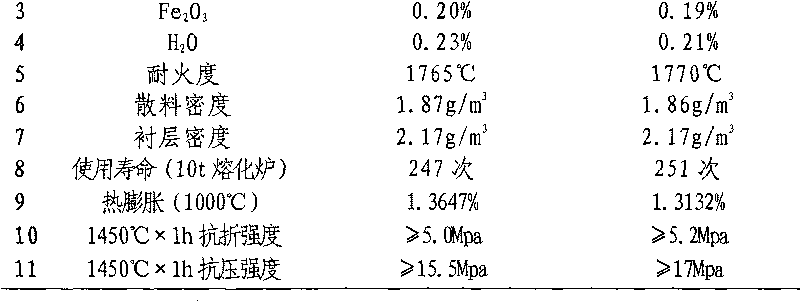

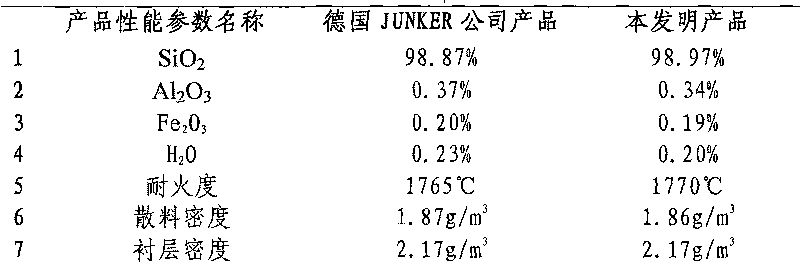

[0024] After testing, the product of the present invention is compared with the main performance of the product of JUNKER company in Germany as follows:

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com