A high-strength high-elongation high-alloy steel and its manufacturing method

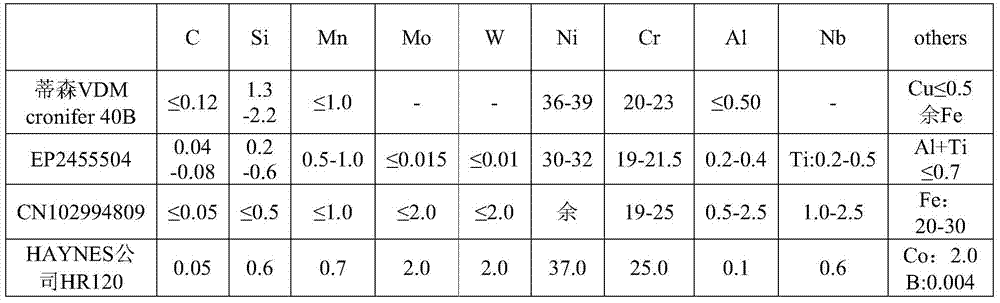

A high-elongation, high-alloy steel technology, applied in the field of high-alloy steel, to achieve the effect of small expansion coefficient and excellent resistance to high temperature oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

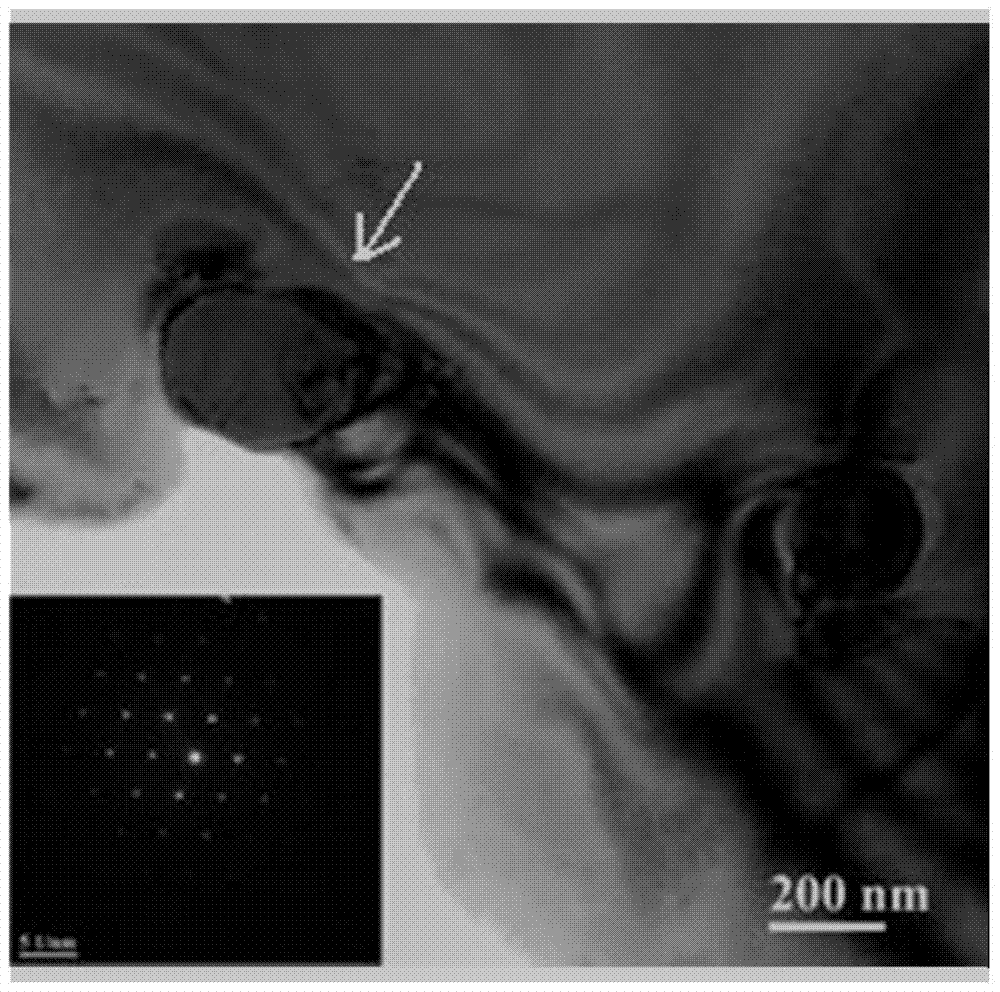

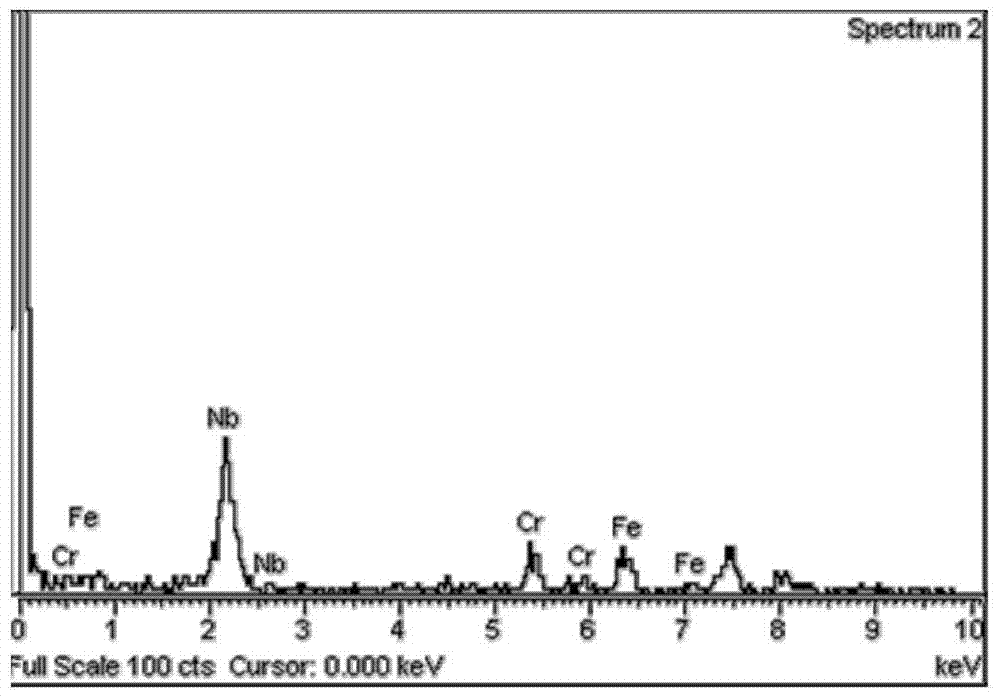

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0068] Refer to Table 3 for the specific ingredients of the examples of the present invention.

[0069] According to the chemical composition requirements of the steel grade of the present invention, the steel billet is smelted in an electric furnace and refined in an LF furnace, softly stirred for a period of time, then added with Al and Nb, cast by a bloom continuous casting machine, and the continuous casting slab is ground at room temperature; The billets are rough-rolled at 1150-1250°C, and then finish-rolled at 1050-1150°C to ensure a reduction rate of 60-95%.

[0070] Before hot rolling, the scale on the surface of the slab is removed first, then 5-7 passes of rough rolling (temperature range 1150-1250°C), and then 5-7 passes of finish rolling (temperature range 1050-1150°C). Annealing and pickling after hot rolling, the hot-rolled sheet is full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| creep strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com