Method for preparing kilogram grade thermistor material

A thermistor, kilogram technology, applied in the field of preparing kilogram negative temperature coefficient thermal materials, can solve the problems of slow scale production of thermal materials and limited research, and achieve the effect of accurate stoichiometric ratio and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

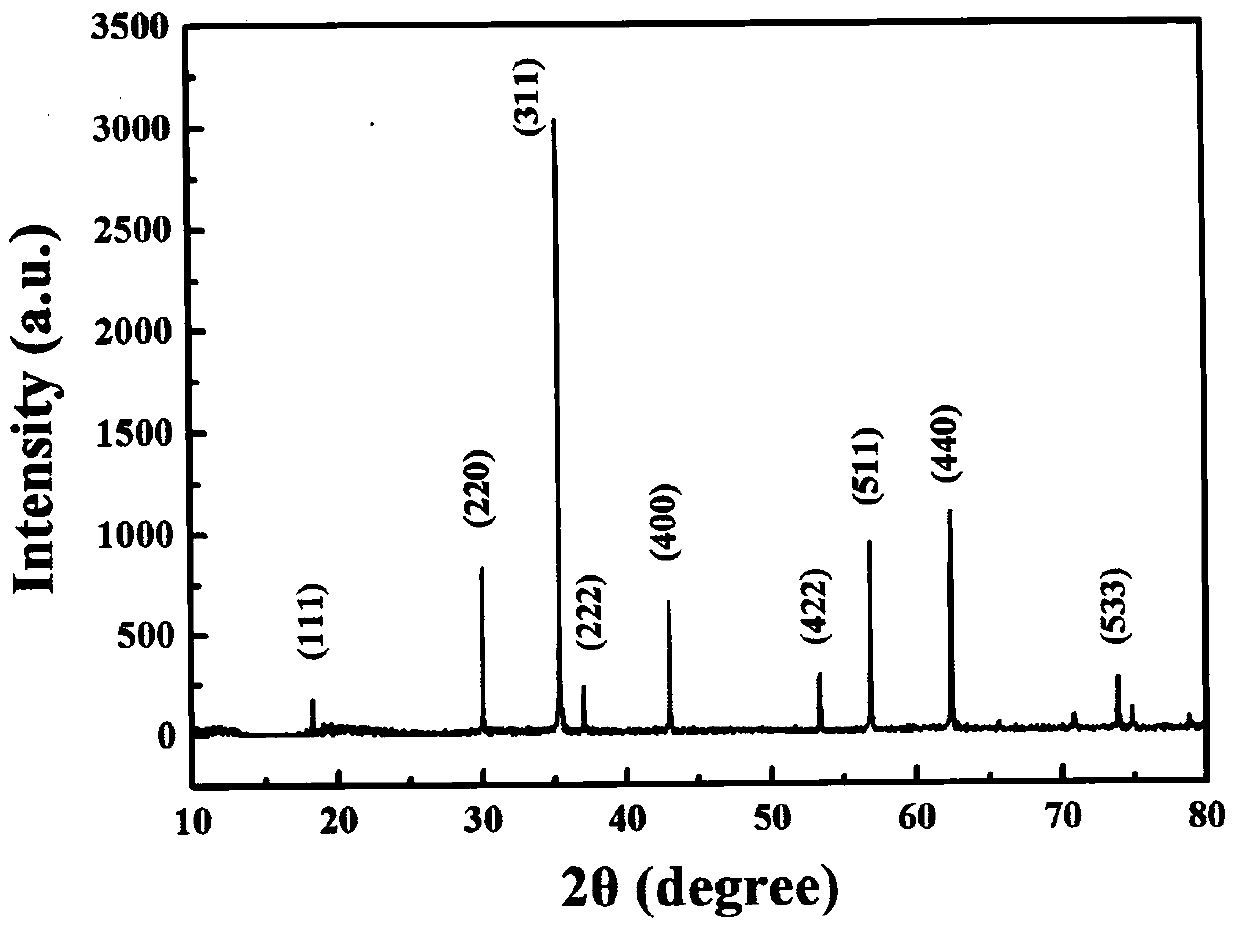

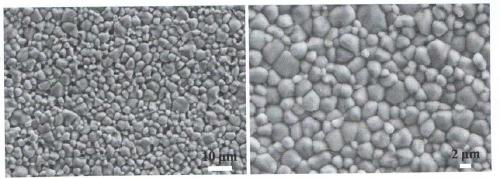

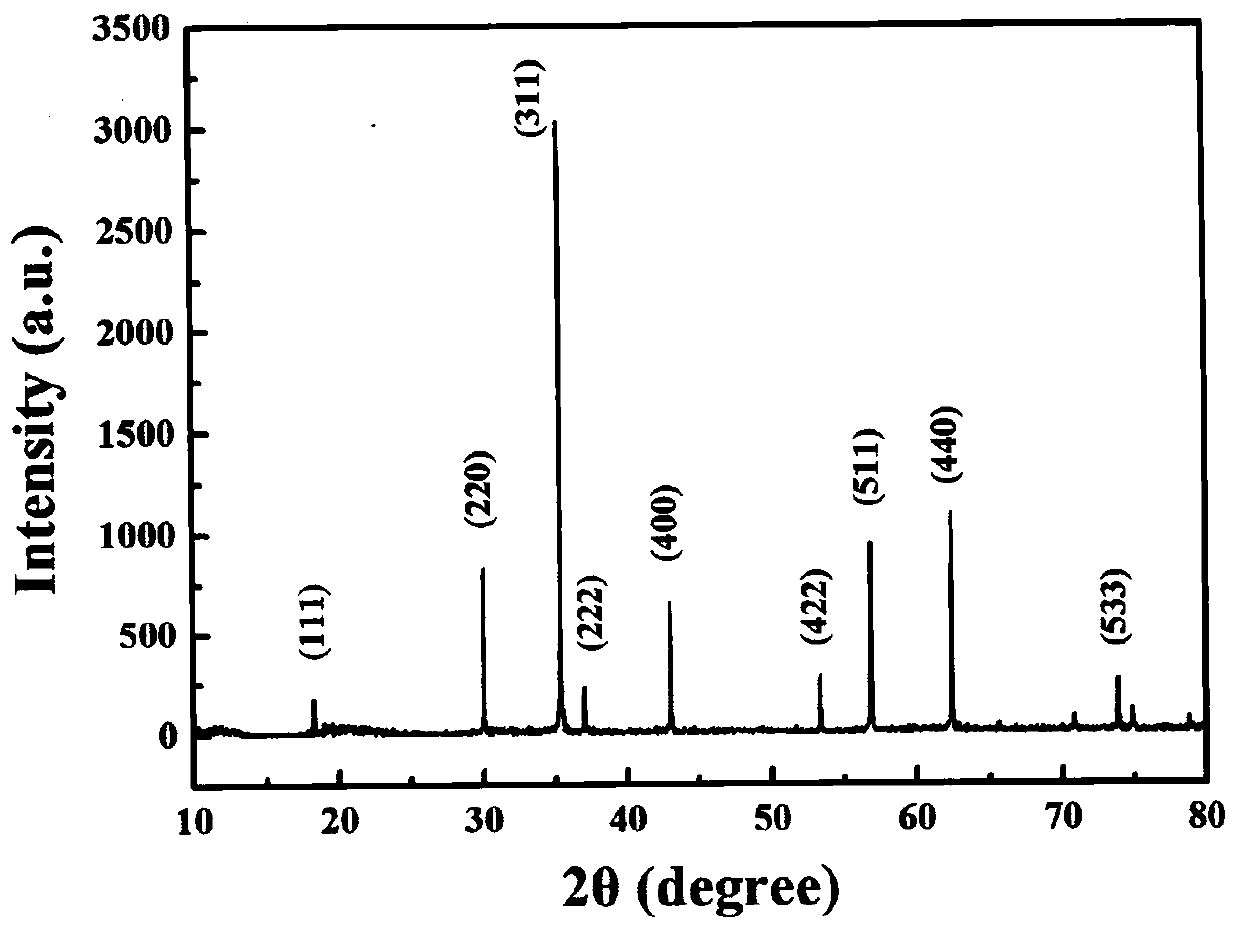

Image

Examples

Embodiment 1

[0014] a. According to the molar ratio of the element Co:Mn:Fe:Zn is 3:0.5:2.5:0, with 193.24g CoSO 4 ·7H 2 O, 19.46gMnSO 4 ·H 2 O and 160.07 g FeSO 4 ·7H 2 O is the raw material, respectively placed in beakers, according to the concentration ratio of the precipitant solution and the raw material solution is 3:1, add 760mL deionized water as the dispersion medium to form a raw material solution, then add 159.41g ammonium bicarbonate dissolved in 2240mL deionized The precipitant ammonium bicarbonate solution formed from water was continuously magnetically stirred at a temperature of 40° C. for 5 hours, and ammonia water was added to adjust the pH of the mixed solution to 7 to obtain a mixed solution;

[0015] b. Transfer the mixed solution obtained in step a into a 5L hydrothermal kettle with a filling degree of 60%, set the reaction temperature at 90°C, the reaction time for 12h, and the stirring speed at 300rpm. After the reaction is complete, cool down naturally. The sl...

Embodiment 2

[0018] According to the molar ratio of the element Co:Mn:Fe:Zn is 1:2.5:1.7:0.8, with 110.18g CoSO 4 ·7H 2 O, 166.46gMnSO 4 ·H 2 O, 186.18g FeSO 4 ·7H 2 O and 90.17g ZnSO 4 ·7H 2 O is the raw material, placed in beakers respectively, according to the concentration ratio of the precipitant solution and the raw material solution is 2:1, add 1300mL deionized water as the dispersion medium to form a raw material solution, then add 270.41g ammonium bicarbonate dissolved in 5700mL deionized The precipitant ammonium bicarbonate solution formed from water was continuously magnetically stirred at a temperature of 40° C. for 3 hours, and ammonia water was added to adjust the pH of the mixed solution to 8 to obtain a mixed solution;

[0019] b. Transfer the mixed solution obtained in step a into a 10L hydrothermal kettle with a filling degree of 70%, set the reaction temperature at 180°C, the reaction time for 6h, and the stirring speed at 100rpm. After the reaction is complete, co...

Embodiment 3

[0022] a. According to the molar ratio of the element Co:Mn:Fe:Zn 2:1.5:2.1:0.4, with 84.75g CoSO 4 ·7H 2 O, 38.41gMnSO 4 ·H 2 O, 88.46g FeSO 4 ·7H 2 O and 17.34 g ZnSO 4 ·7H 2 O is the raw material, placed in beakers respectively, according to the concentration ratio of the precipitant solution and the raw material solution is 4:1, add 500mL deionized water as the dispersion medium to form a raw material solution, then add 104.37g ammonium bicarbonate dissolved in 1100mL deionized The precipitant ammonium bicarbonate solution formed from water was continuously magnetically stirred at a temperature of 40° C. for 4 hours, and ammonia water was added to adjust the pH of the mixed solution to 9 to obtain a mixed solution;

[0023]b. Transfer the mixed solution obtained in step a into the lining of a 2L hydrothermal kettle with a filling degree of 80%, set the reaction temperature at 150°C, the reaction time for 9 hours, and the stirring speed at 150rpm. After the reaction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com