Method for producing thin ta4 titanium material by coil cold rolling method

A cold rolling, titanium technology, applied in the production field of thin TA4 titanium, can solve the problems of structure and performance fluctuation, batch-to-batch fluctuation, poor surface quality, etc., to achieve fine and uniform structure, strong batch consistency, Good batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Select high-quality grade 0 small particles (3~12.7mm particle size) sponge titanium, screen out fine titanium powder, edge skin, bluish black particles and hard blocks and other defective sponge titanium, and evenly add small pieces of pure iron flakes on the automatic material distribution system and TiO 2 Powder (purity ≥ 99%), electrode welding is performed in a vacuum welding chamber after pressing the electrode. The German ALD vacuum consumable electric arc furnace is used for three times of melting, peeling, forging and shaping to obtain a square slab. After milling, the ultrasonic flaw detection test is A-level. The nominal size of the slab is 200×1060×5500mm, and the TA4 slab Nominal composition Ti-0.3%Fe-0.25%O;

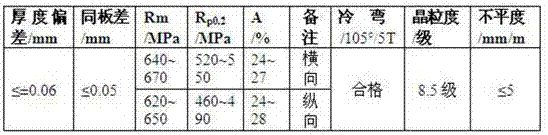

[0036] The slab is heated by natural gas in a walking furnace, and the furnace temperature is controlled at 870-920°C. When the furnace temperature is stable at ≥880°C, it is kept for 200-320 minutes and then rolled out of the furnace. The rough rol...

Embodiment 2

[0043] Select high-quality 0-grade sponge titanium, screen and pick out defective titanium sponge such as fine titanium powder, edge skin, bluish black particles and hard blocks, smelting and forging are the same as in Example 1, forging and shaping to obtain a square slab, and ultrasonically after milling The flaw detection is Class A, the nominal size of the slab is 200×1060×5500mm, and the nominal composition of the TA4 slab is Ti-0.32%Fe-0.25%O.

[0044] Production of hot-rolled coils: the production process is the same as in Example 1, and the specifications of the hot-rolled coils are 3.5mm×1050mm×about 300m.

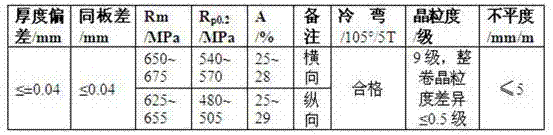

[0045] Production of cold-rolled coils: Hot-rolled coils are produced after partial surface grinding to remove defects. For 1.2mm finished coils and strips, the production design is that the thickness of hot-rolled coils is 3.5mm → the deformation in the first rolling process is 41% to 2.05mm thick→690℃vacuum bell-type furnace coil annealing→second rolling process...

Embodiment 3

[0050] Select high-quality 0-grade sponge titanium, screen and pick out defective titanium sponge such as fine titanium powder, edge skin, bluish black particles and hard blocks, smelting and forging are the same as in Example 1, forging and shaping to obtain a square slab, and ultrasonic after milling 25%O。 The flaw detection test is A grade, the nominal size of the slab is 200 × 1060 × 5500mm, and the nominal composition of the TA4 slab is Ti-0.32%Fe-0. 25%O.

[0051] Production of hot-rolled coils: the production process is the same as in Example 1, and the specifications of the hot-rolled coils are 5mm×1050mm×about 300m.

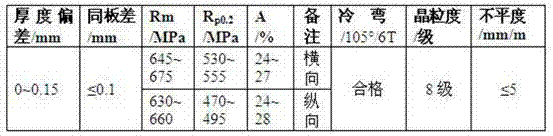

[0052] Production of cold-rolled coils: hot-rolled coils are produced after partial surface grinding to remove defects. For finished coils and strips of 3mm (required thickness tolerance 0~+0.15mm), the production design is 5mm thick for hot-rolled coils → Deformation of 38% to 3.12mm thick in the first rolling process → Slitting into plates of required ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com