Floating type vegetation concrete and preparation method thereof

A technology for planting raw concrete and concrete, applied in the field of building materials, which can solve the problems of bulk density, concrete corrosion, and brittleness of the slurry coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

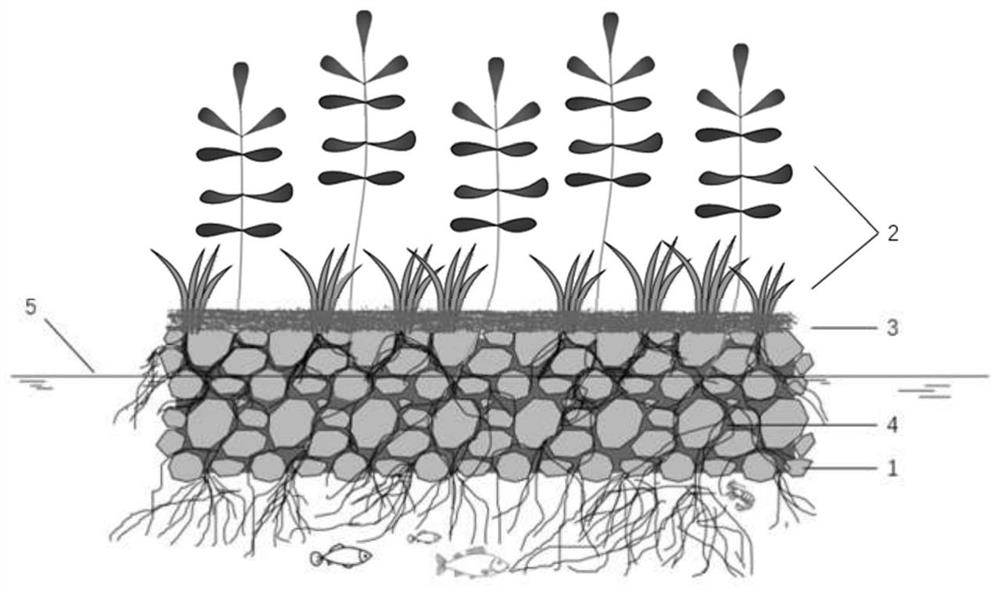

[0060] Embodiment 1 A kind of floating type planting concrete

[0061] The floating type vegetation concrete described in this embodiment includes a concrete matrix and a vegetation matrix. The raw material composition of the concrete matrix is (1 weight part=1Kg):

[0062] 105 parts by weight of low alkalinity sulfoaluminate cement, 30 parts by weight of fly ash, 15 parts by weight of modified rubber powder, 364 parts by weight of ceramsite, 2.3 parts by weight of polycarboxylate water reducing agent and 45 parts by weight of water; wherein, Low alkalinity sulfoaluminate cement, fly ash and modified rubber powder are cementitious materials, and ceramsite is coarse aggregate.

[0063] The vegetative substrate includes plant seeds and nutrient soil.

[0064] The floating lightweight plant concrete is prepared by the following method:

[0065] I. Preparation of concrete matrix

[0066] I-1. Weigh each raw material according to the proportion;

[0067] 1-2. Add an appropri...

Embodiment 2

[0075] Embodiment 2 A kind of floating type planting concrete

[0076] The floating type vegetation concrete described in this embodiment includes a concrete matrix and a vegetation matrix. The raw material composition of the concrete matrix is (1 weight part=1Kg):

[0077] 99 parts by weight of low alkalinity sulfoaluminate cement, 28 parts by weight of fly ash, 14 parts by weight of modified rubber powder, 364 parts by weight of ceramsite, 2.1 parts by weight of polycarboxylate water reducing agent and 42 parts by weight of water.

[0078] The vegetative substrate includes plant seeds and nutrient soil.

[0079] The floating lightweight plant concrete is prepared by the following method:

[0080] I. Preparation of concrete matrix

[0081] I-1. Weigh each raw material according to the proportion;

[0082] 1-2. Add an appropriate amount of water to the ceramsite, fully infiltrate, leave standstill for 1 hour, and after removing the surface free water, obtain the ceramsit...

Embodiment 3

[0089] Embodiment 3 A kind of floating type planting concrete

[0090] The floating type vegetation concrete described in this embodiment includes a concrete matrix and a vegetation matrix. The raw material composition of the concrete matrix is (1 weight part=1Kg):

[0091] 92 parts by weight of low alkalinity sulfoaluminate cement, 26 parts by weight of fly ash, 13 parts by weight of modified rubber powder, 364 parts by weight of ceramsite, 2 parts by weight of polycarboxylate water reducing agent and 39 parts by weight of water.

[0092] The vegetative substrate includes plant seeds and nutrient soil.

[0093] The floating lightweight plant concrete is prepared by the following method:

[0094] I. Preparation of concrete matrix

[0095] I-1. Weigh each raw material according to the proportion;

[0096] 1-2. Add an appropriate amount of water to the ceramsite, fully infiltrate, leave standstill for 1 hour, and after removing the surface free water, obtain the ceramsite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com