Flue gas dry-type method for simultaneously desulfurizing and denitrating

A technology for desulfurization, denitrification and flue gas, which is applied in the field of flue gas purification, can solve the problems of operating cost, limited reaction activity operating temperature, high equipment investment and operating cost, and large floor space, so as to achieve the removal rate and efficiency, The effect of small footprint and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

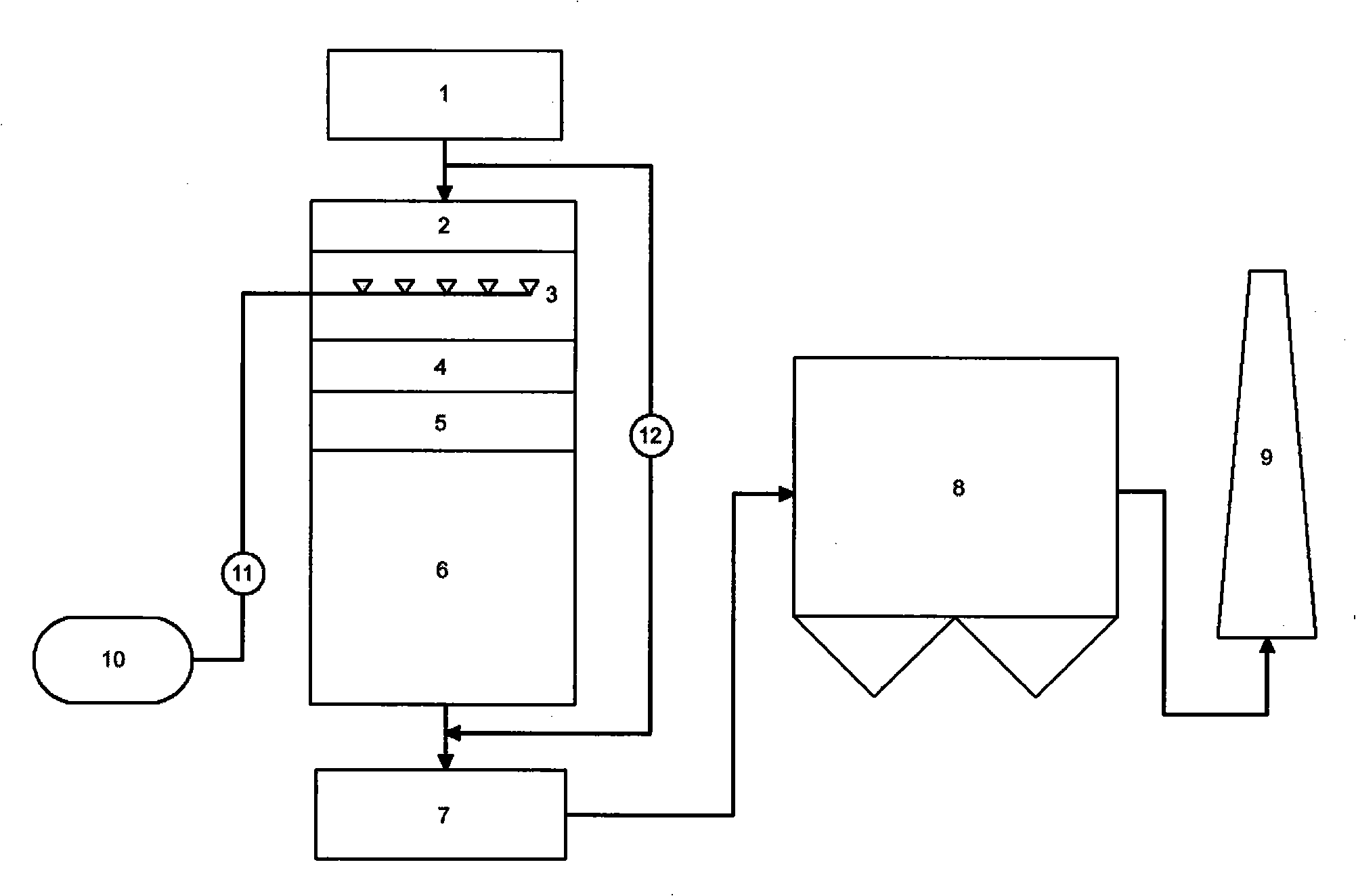

Method used

Image

Examples

Embodiment 1

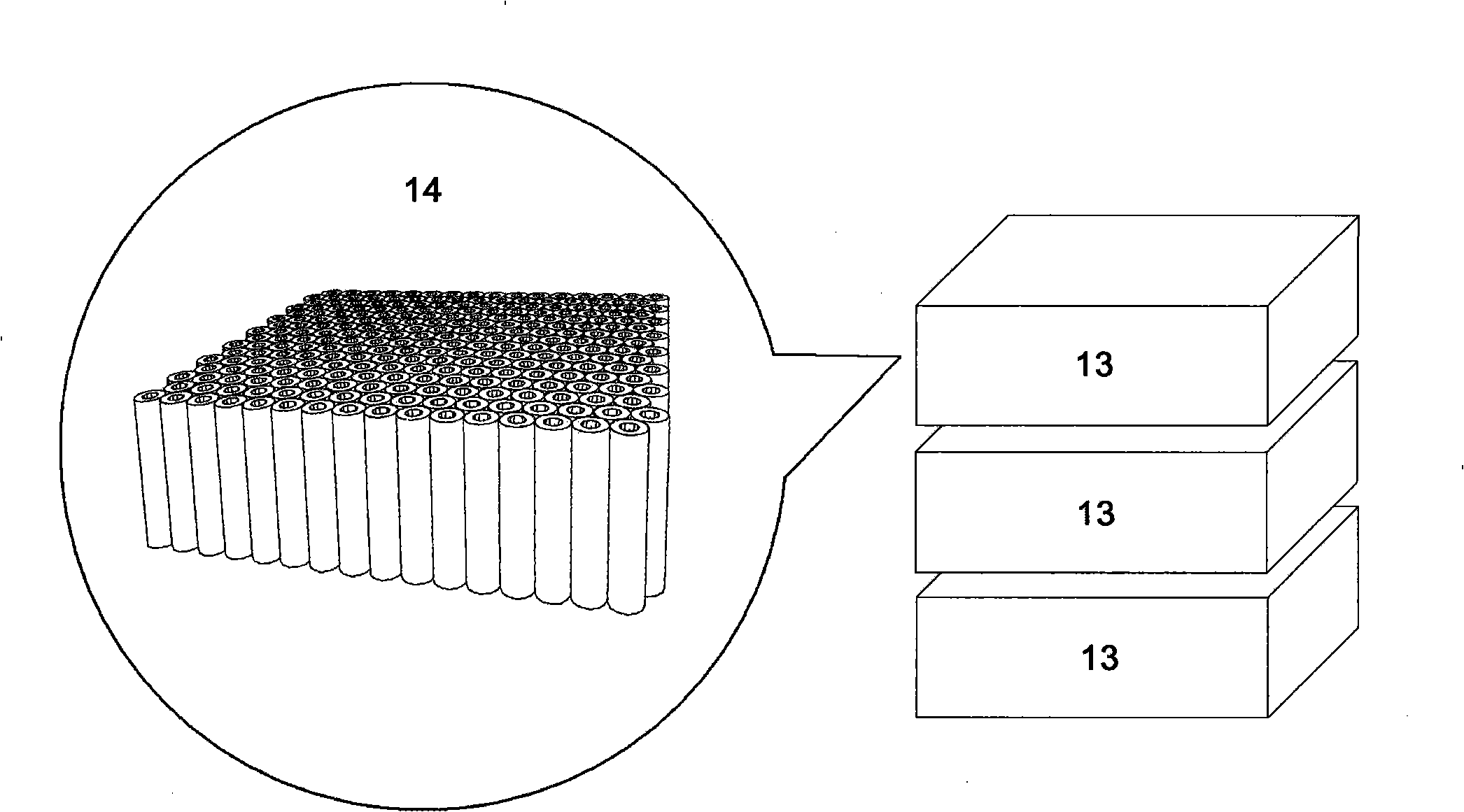

[0024] One composition is: 64wt% SiO 2 , 29 wt% Al 2 o 3 , 5 wt% Fe 2 o 3 , 1 wt% Fe 2 (SO 4 ) 3 , 1wt% CaO circular tube catalysts are closely arranged in a matrix into modules whose growth, width, and height are 150mm×144mm×100mm, and 4 modules are placed in series and vertically, and the interval between adjacent modules is 50mm; a filter screen is arranged before the catalyst bed , grid width 10mm.

[0025] The catalyst bed layer obtained by the above method, at 1050ppm SO 2 , 5% O 2 , 500ppm NO, humidity is 2%, the rest is N 2 In the atmosphere, the space velocity is 5000h -1 , NH 3 Under the test condition that the molar ratio of injection amount to NO content in the flue gas is 1, the denitrification rate is higher than 80%, the desulfurization rate is higher than 60%, and the sulfur capacity reaches 4 %(weight).

[0026] After the catalyst is saturated with sulfur, it is ventilated and calcined at 450°C for 5 hours, and then tested under the same condition...

Embodiment 2

[0028] One composition is: 80wt% SiO 2 , 8 wt% Al 2 o 3 , 8 wt% Fe 2 o 3 , 1 wt% Fe 2 (SO 4 ) 3, 3wt% CaO circular tube-shaped catalysts are closely arranged in a matrix into modules whose growth, width and height are 150mm×144mm×50mm respectively. Two modules are placed in series and vertically, and the interval between adjacent modules is 1000mm; a filter screen is arranged in front of the catalyst bed , grid width 50mm.

[0029] The catalyst bed layer obtained by the above method, at 1050ppm SO 2 , 5% O 2 , 500ppm NO, 10% H 2 O (volume concentration, the rest is N 2 ) atmosphere, the space velocity is 2000h -1 , NH 3 Under the test condition that the molar ratio of the injection amount to the NO content in the flue gas is 1.2, the denitrification rate is higher than 80%, the desulfurization rate is higher than 60%, and the sulfur capacity reaches 6 %(weight).

[0030] After the catalyst is saturated with sulfur, it is ventilated and calcined at 500°C for 2 hou...

Embodiment 3

[0032] One composition is: 61wt% SiO 2 , 18.8 wt% Al 2 o 3 , 20wt% Fe 2 o 3 , 0wt% Fe 2 (SO 4 ) 3 , the circular tubular catalyst of 0.2wt% CaO is closely arranged in a matrix into modules whose growth, width, and height are 150mm×144mm×200mm respectively, and are placed vertically in series with 3 modules, with an interval of 50mm between adjacent modules; a filter is arranged before the catalyst bed Mesh, grid width 50mm.

[0033] The catalyst bed layer obtained by the above method, at 1050ppm SO 2 , 5% O 2 , 500ppm NO, 2% H 2 O (volume concentration, the rest is N 2 ) atmosphere, the space velocity is 20000h -1 , NH 3 Under the test condition that the molar ratio of the injection amount to the NO content in the flue gas is 1.2, the denitrification rate is higher than 75%, the desulfurization rate is higher than 50%, and the sulfur capacity reaches 17wt in the flue gas temperature range of 310 ° C ~ 400 ° C %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com