Molybdenum disulfide thin film gas sensitive material, preparation method and application

A technology of gas-sensing materials and thin-film materials, which is applied in the field of MoS2 thin-film gas-sensing materials, molybdenum disulfide thin-film gas-sensing materials and preparation fields, can solve the problem of inability to guarantee the thickness uniformity and the consistency of the number of layers, the growth quality and the growth area. The problems of poor controllability and low detection accuracy of complex gas environment have achieved the effect of remarkable NO2 response performance, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

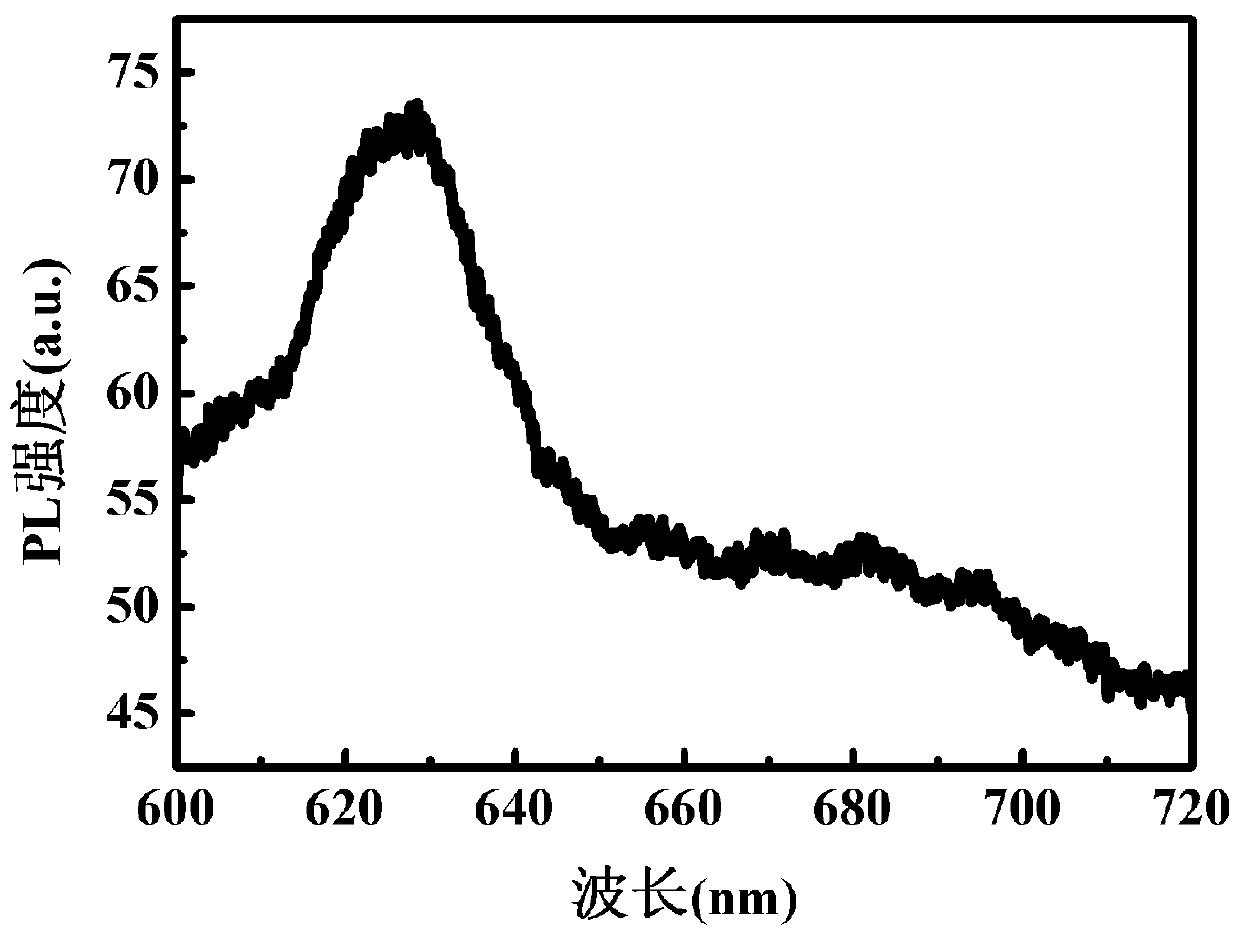

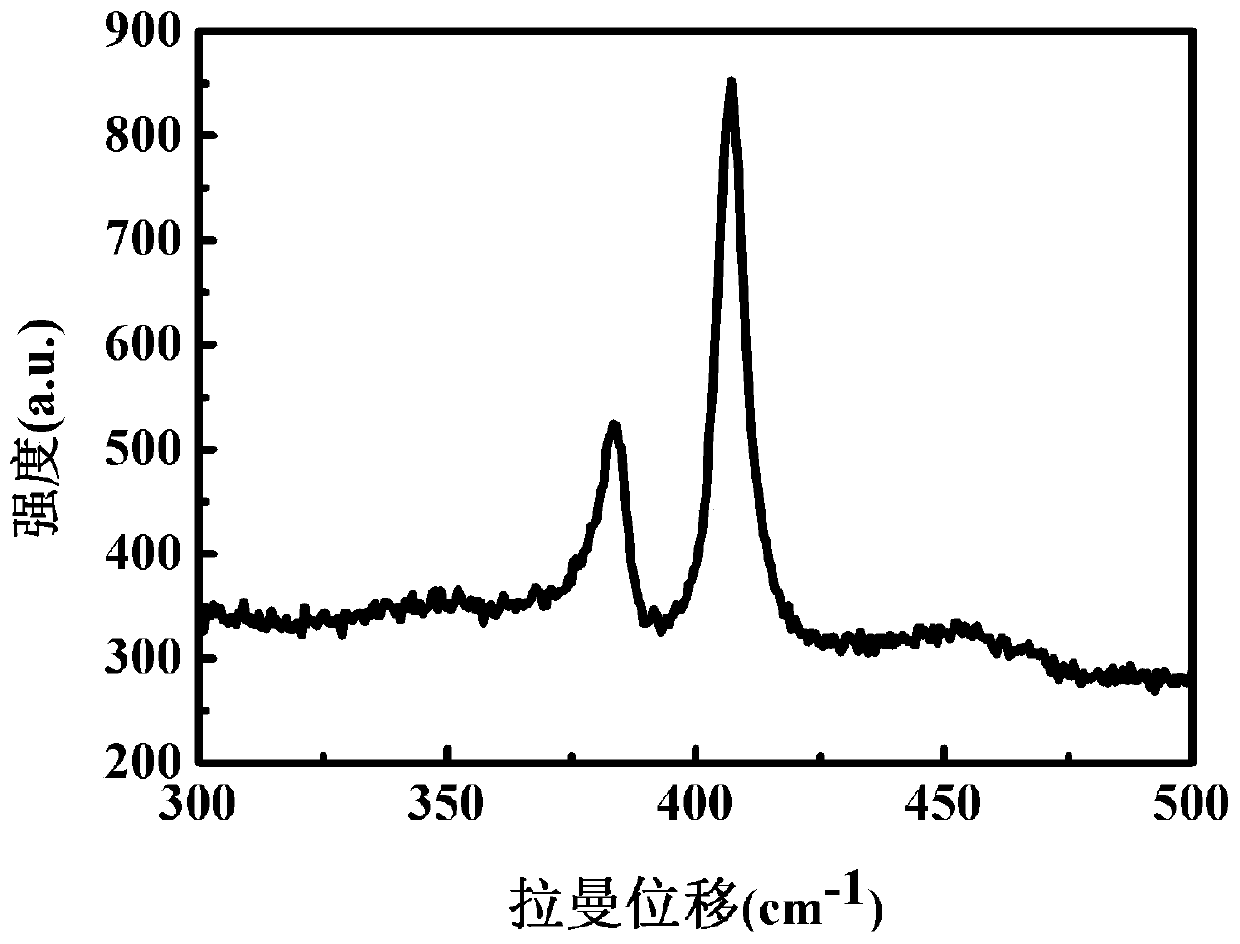

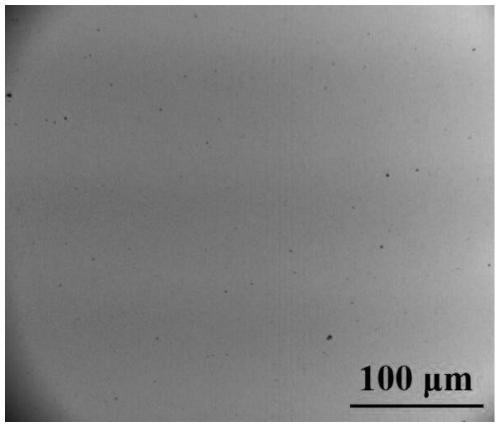

[0049] A method for detecting NO 2 Gas MoS 2 A thin-film gas-sensitive material and a preparation method thereof, the preparation method comprising the following steps:

[0050] 1. Preparation of single-layer or few-layer MoS by CVD method 2 Thin film gas sensitive materials;

[0051] The aforementioned growth on SiO 2 / MoS on the surface of Si substrate 2 Sensitive material area is about 0.25cm 2 , the 2D MoS 2 Gas-sensitive material preparation method:

[0052] ①Using electron beam evaporation on SiO 2 / Si substrate is pre-plated to obtain a molybdenum layer with a thickness of 1nm. The electron beam evaporation is plated on the substrate at a deposition rate of 0.1A / s. The above-mentioned SiO 2 / SiO in Si substrate 2 The thickness of the layer is 300 nm.

[0053] ② Grinding block sulfur into powder and laying it flat in a porcelain boat, the block sulfur is 0.8g of high purity sulfur with a purity of 99.99%;

[0054] ③ Place the porcelain boat covered with high-p...

Embodiment 2

[0067] A method for detecting NO 2 Gas MoS 2 A thin-film gas-sensitive material and a preparation method thereof, the preparation method comprising the following steps:

[0068] 1. Preparation of single-layer or few-layer MoS by CVD method 2 Thin film gas sensitive materials;

[0069] The area of the above-mentioned sensitive material grown on the surface of the substrate is about the size of a substrate, which is 0.1cm 2 , the 2D MoS 2 Nanosheets are prepared by a method comprising the following steps:

[0070] ①Using electron beam evaporation on SiO 2 / Si substrate is pre-plated to obtain a molybdenum atomic layer with a thickness of 1nm, and the electron beam evaporation is plated on the substrate with a deposition rate of 0.1A / s. The above-mentioned SiO 2 The thickness of the / Si substrate is 300 nm.

[0071] ② Grinding block sulfur into powder and laying it flat in a porcelain boat, the block sulfur is 0.8g of high purity sulfur with a purity of 99.99%;

[0072]...

Embodiment 3

[0080] A method for detecting NO 2 Gas MoS 2 A thin-film gas-sensitive material and a preparation method thereof, the preparation method comprising the following steps:

[0081] 1. Preparation of single-layer or few-layer MoS by CVD method 2 Thin film gas sensitive materials;

[0082] The area of the above-mentioned sensitive material grown on the surface of the substrate is about the size of a substrate, which is 1cm 2 , the 2D MoS 2 Nanosheets are prepared by a method comprising the following steps:

[0083] ①Using electron beam evaporation on SiO 2 / Si substrate is pre-plated to obtain a molybdenum atomic layer with a thickness of 1nm. The electron beam evaporation is plated on the substrate at a deposition rate of 0.1A / s. The above-mentioned SiO 2 The thickness of the / Si substrate is 300 nm.

[0084] ② Grinding massive sulfur into powder and laying it flat in a porcelain boat. The massive sulfur is 0.8g of high-purity sulfur with a purity of 99.99%.

[0085] ③ P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com