Micro-fluidic combined chemical reaction chip

A microfluidic chip and chemical reaction technology, applied in the field of microfluidics, can solve the problems of cumbersome operation, large consumption of reagents, and high requirements for operators, and achieve the effect of low sample consumption and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

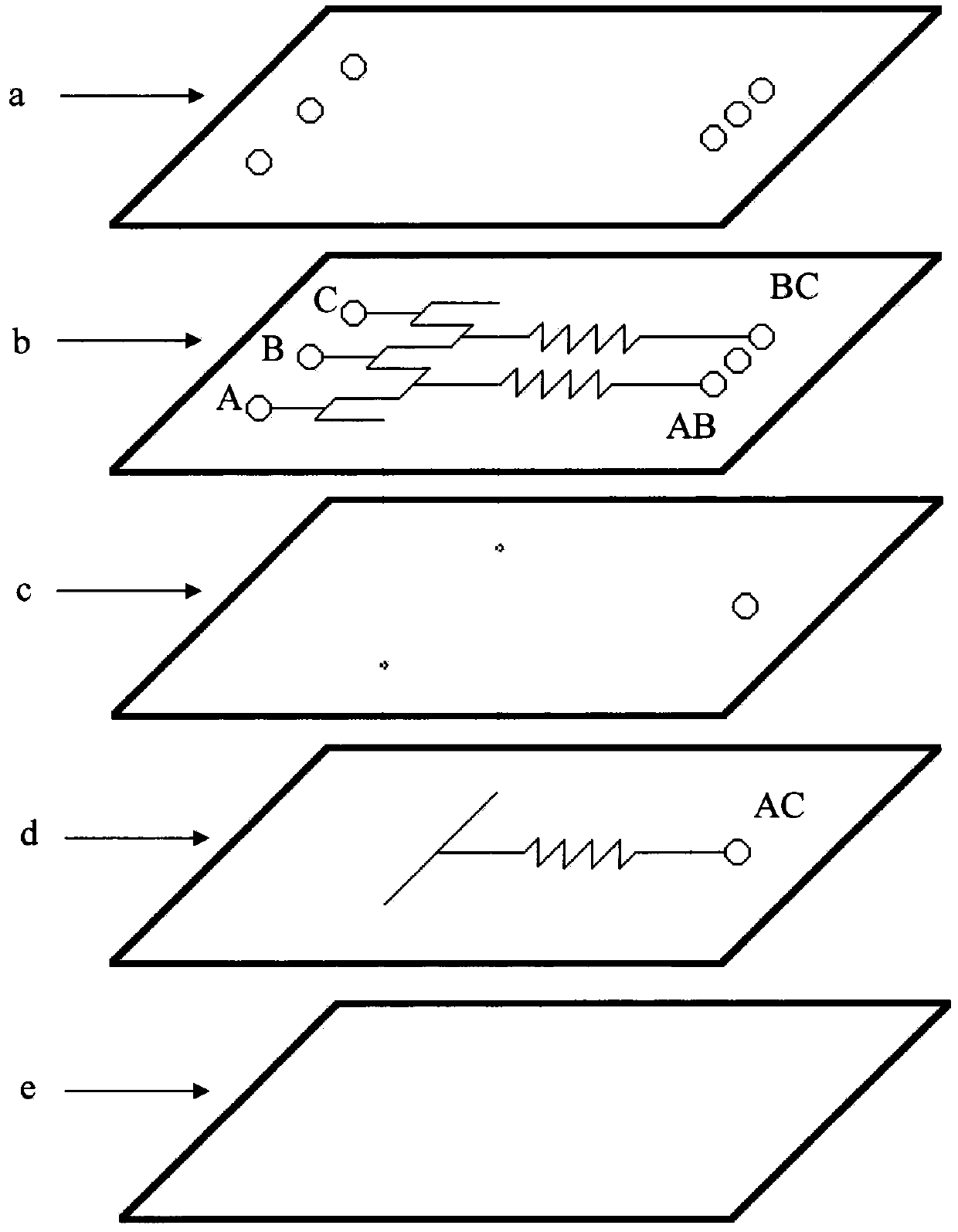

[0017] Example 1 A microfluidic chip for pairwise reaction of three samples

[0018] In order to realize the combination chemical reaction of three samples in pairs, this embodiment proposes a microfluidic reaction chip, which is processed by PMMA. Such as figure 1 As shown, the microfluidic chip is composed of five layers of substrates, which are cover sheet a with fluid inlet and outlet holes, substrate b with mixed reaction unit, substrate c with through holes, and another mixed reaction unit with Substrate d, blank substrate e. Among them, different sample inlets are processed on the cover sheet a, which are used to introduce three different samples A, B, and C; Sheet c has a through-hole structure connecting the upper and lower substrates; substrate d has AC mixing intersection, mixing reaction and product outlets for use.

[0019] When using the above-mentioned microfluidic chip for combinatorial chemical synthesis, it is only necessary to pass samples A, B, and C int...

Embodiment 2

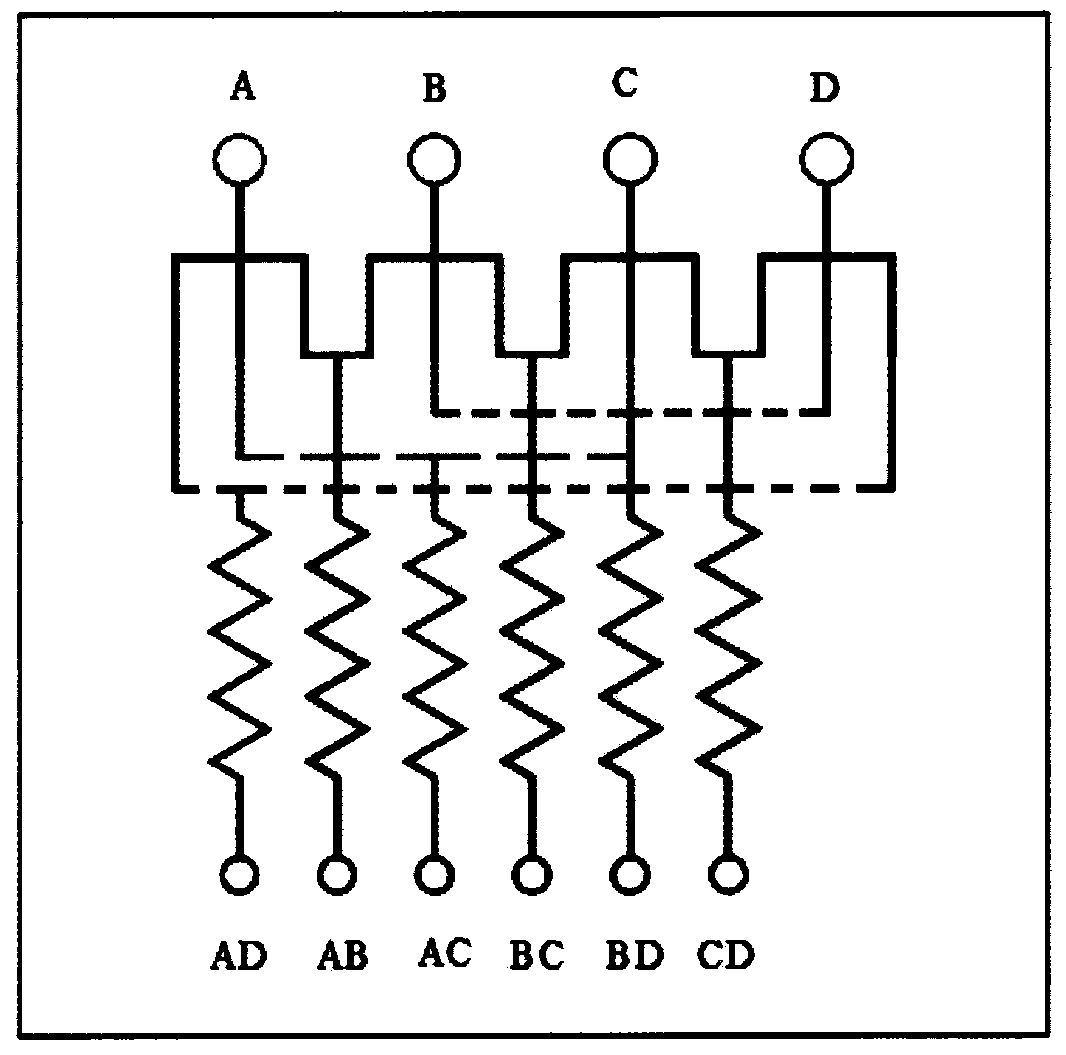

[0020] Example 2 A microfluidic chip for pairwise reaction of four samples

[0021] In order to realize chemical reactions in pairs of four samples, this embodiment proposes a microfluidic reaction chip processed by PMMA. Such as figure 2 As shown, the microfluidic chip is composed of a sample inlet, a sample converging channel, a mixing channel and a product outlet.

[0022] When using the above-mentioned microfluidic chip for combinatorial chemical synthesis, it is only necessary to pass samples A, B, C, and D into the sample inlet, and adjust a certain flow rate, then the sample solution flows through the intersection channel and the mixing channel in the microfluidic chip. Finally, a chemical reaction occurs, and six products of AB, AC, AD, BC, BD and CD can be collected continuously at the product outlet of the microfluidic chip.

Embodiment 3

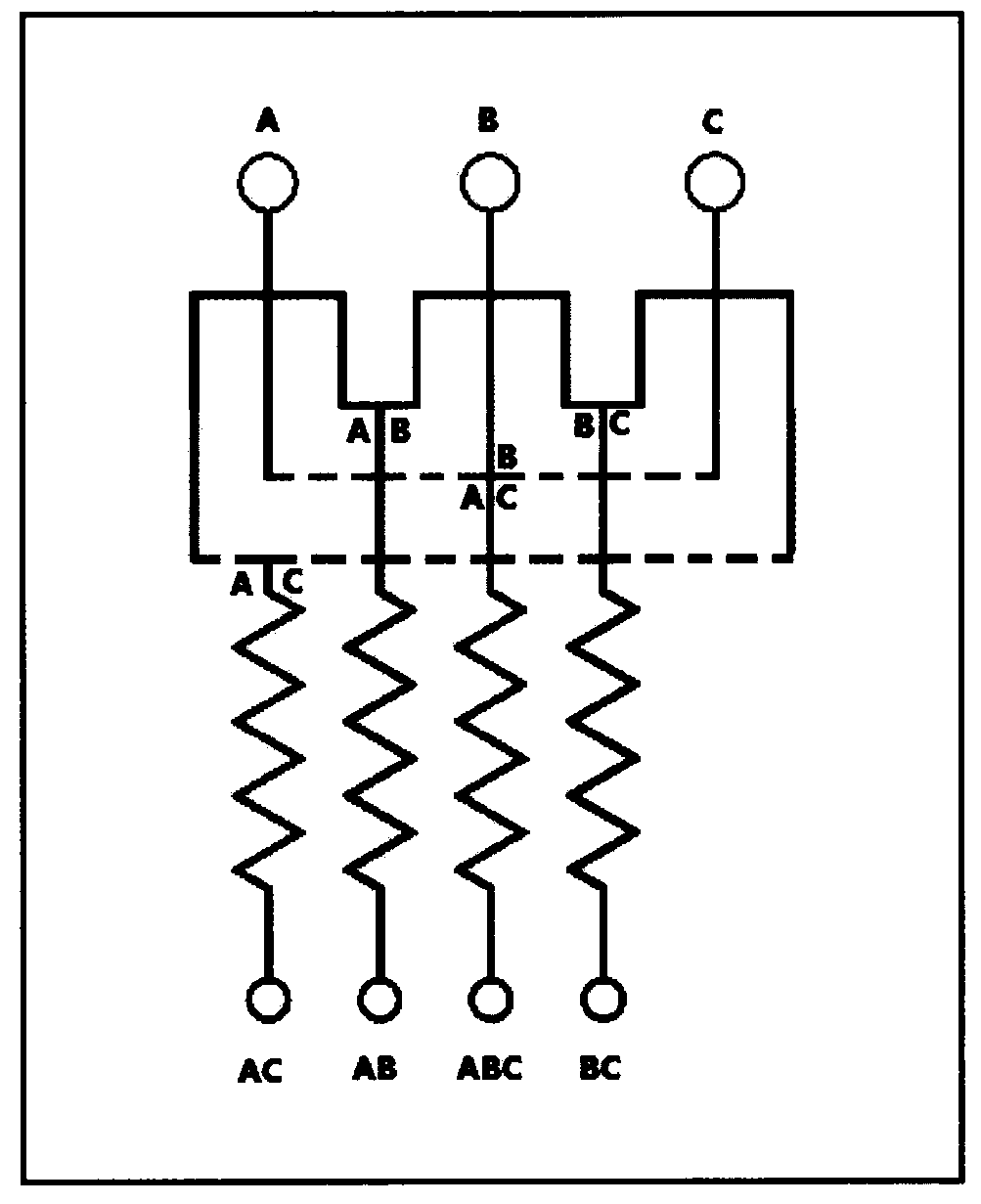

[0023] Example 3 Schematic diagram of a microfluidic chip for any combination of three samples.

[0024] In order to realize the chemical reaction of any combination of the three samples, this embodiment proposes a microfluidic reaction chip, which is processed by polycarbonate. Such as image 3 As shown, the microfluidic chip is composed of a sample inlet, a sample converging channel, a mixing channel and a product outlet.

[0025] When using the above-mentioned microfluidic chip for combinatorial chemical synthesis, it is only necessary to pass samples A, B, and C into the sample inlet, and adjust a certain flow rate. After the sample solution flows through the converging channel and mixing channel in the microfluidic chip, When a chemical reaction occurs, four products AB, AC, BC and ABC can be collected continuously at the product outlet of the microfluidic chip.

[0026] Compared with the existing combinatorial chemical reaction methods, the combinatorial chemical react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com