Apparatus and method for hydrogen oxygen composite reaction

A reaction, hydrogen and oxygen technology, applied in the direction of chemical methods, reactors, emergency protection devices, etc. that make gaseous medium react with gaseous medium, can solve the problem of heat removal, etc., and achieve high operating flexibility, no hot spots, and convenient heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

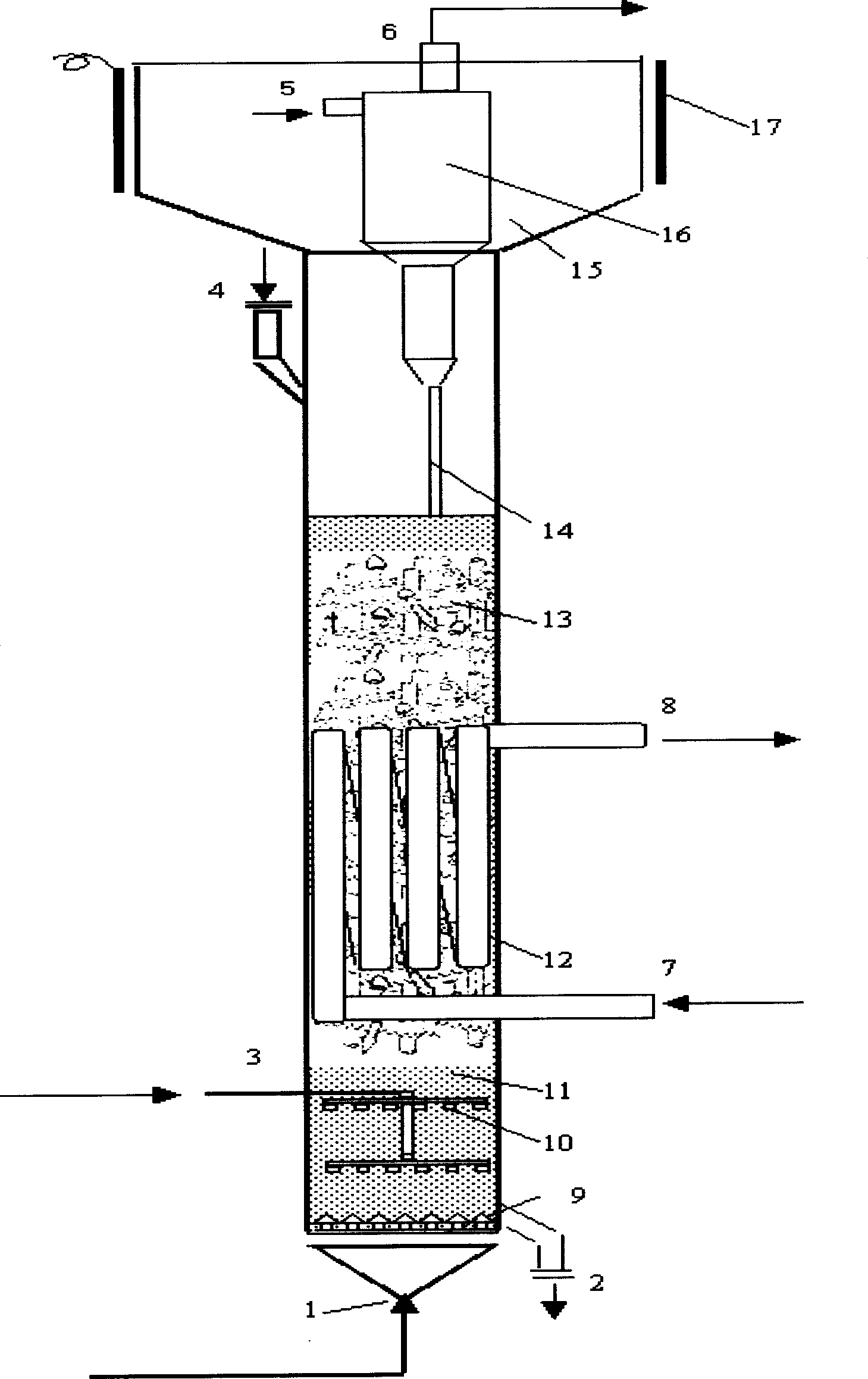

[0052] figure 1 It is a schematic diagram of the structure of the hydrogen-oxygen recombination reaction device provided by the present invention. The oxygen distributor 9 adopts a hood structure, the hydrogen distributor 10 adopts a double-layer ring pipe structure, the internal member 13 is a ridge-shaped internal member, and the catalyst dense phase zone 11 A built-in heat exchanger 12 is adopted, and a heater 17 is provided in the expansion section 15 of the reactor, and the heater 17 adopts an external heating method.

[0053] in such as figure 1 The reaction is carried out in the fluidized bed reactor shown for the hydrogen-oxygen recombination reaction. A catalyst with a platinum content of 200 mg / kg is used, its average particle size is 60 μm, and its loading capacity is 1000 g. First feed pure oxygen from the oxygen distributor 9 with a flow rate of 1Nm 3 / h, start the heating device to make the temperature of the catalyst zone higher than 100°C. Then, pure hydrog...

Embodiment 2

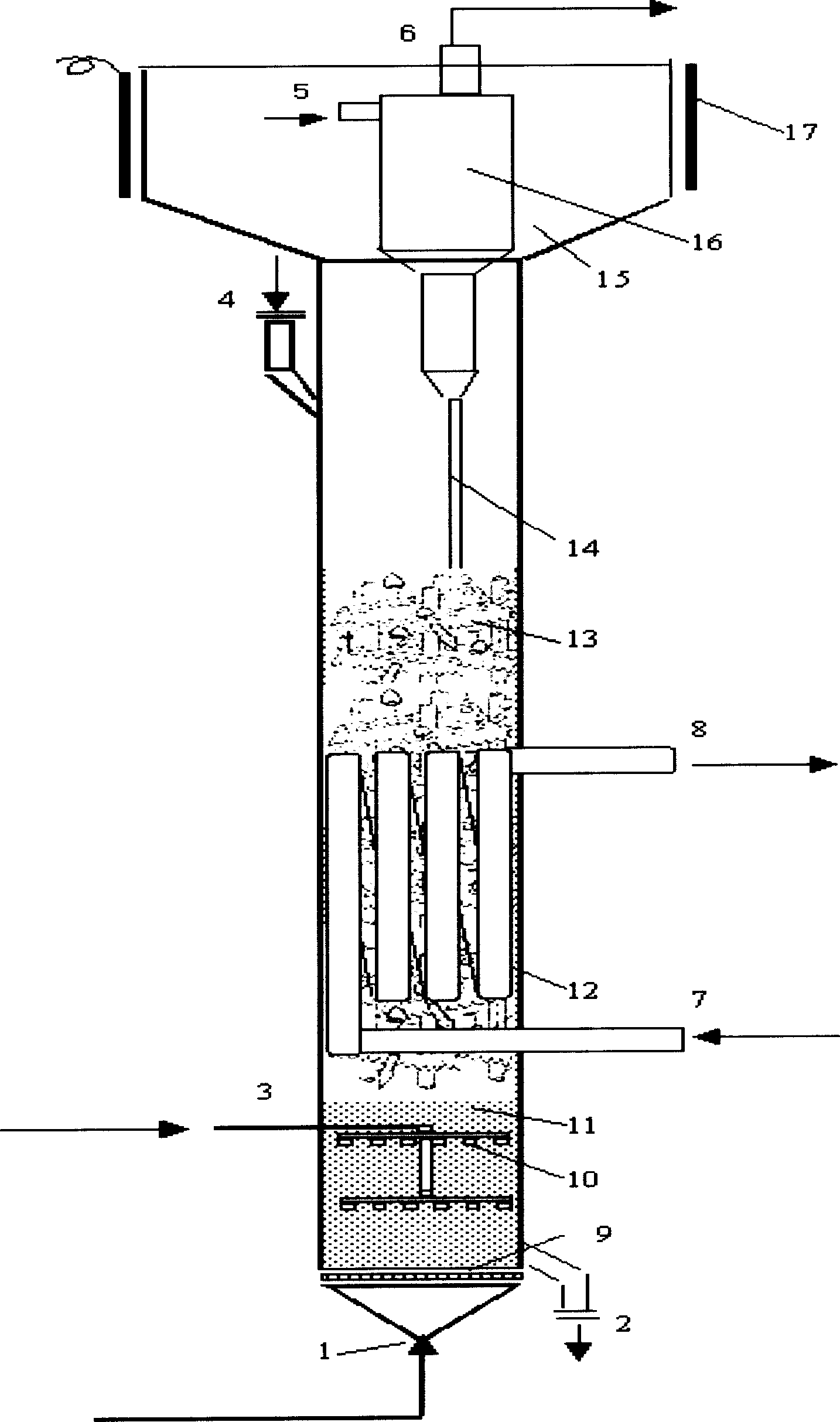

[0055] figure 2 It is a schematic diagram of the structure of the hydrogen-oxygen recombination reaction device provided by the present invention. The oxygen distributor 9 adopts a plate structure, the hydrogen distributor 10 adopts a double-layer ring pipe structure, the internal member 13 is a ridge-shaped internal member, and the catalyst dense phase zone 11 adopts Built-in heat exchanger, the reactor expansion section 15 is provided with a heater 17, and the heater 17 adopts an external heating method.

[0056] in such as figure 2 The reaction is carried out in the fluidized bed reactor shown for the hydrogen-oxygen recombination reaction. A catalyst with a platinum content of 300 mg / kg was used, its average particle size was 300 μm, and its loading capacity was 360 g. First feed pure oxygen from the oxygen distributor 9 with a flow rate of 1Nm 3 / h, start the heating device to make the temperature of the catalyst zone higher than 100°C. Then, pure hydrogen is gradua...

Embodiment 3

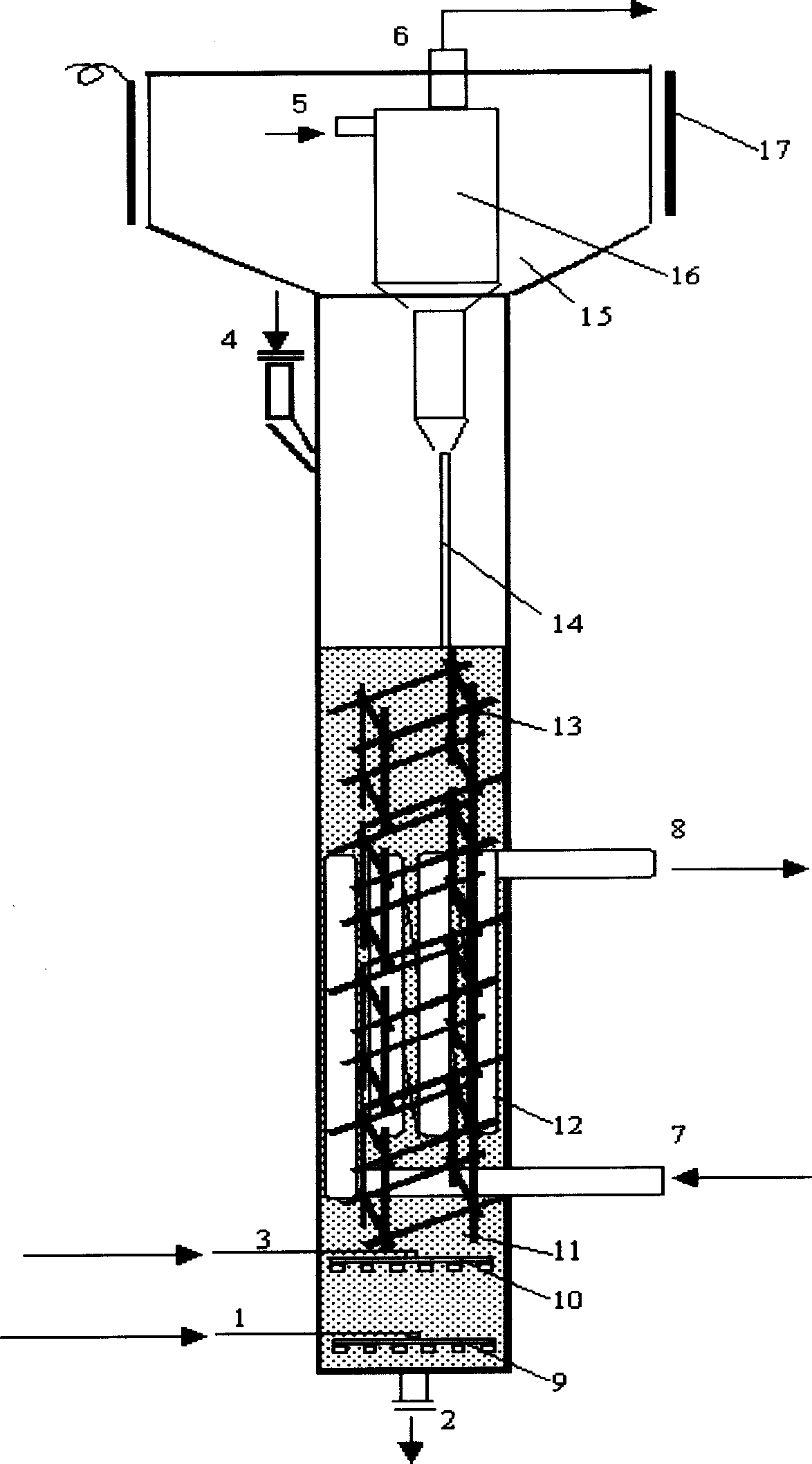

[0058] image 3 It is a schematic diagram of the structure of the device for the hydrogen-oxygen recombination reaction provided by the present invention. The oxygen distributor 9 adopts an annular structure, the hydrogen distributor 10 adopts a single-layer annular structure, and the internal member 13 is a grid-shaped internal member, and the catalyst is densely phased. The zone 11 adopts a built-in heat exchanger, and the reactor expansion section 15 is provided with a heater 17, and the heater 17 adopts an external heating method.

[0059] in such as image 3 The reaction is carried out in the fluidized bed reactor shown for the hydrogen-oxygen recombination reaction. A catalyst containing 200 mg / kg of palladium is used, the average particle size is 45 μm, and the loading amount is 1000 g. First feed pure oxygen from the oxygen distributor 9 with a flow rate of 1.5Nm 3 / h, start the heating device to make the temperature of the catalyst zone higher than 100°C. Then, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com